Finned tube heat exchanger and air conditioner

A technology of heat exchanger and tube-fin type, which is applied in the field of tube-fin heat exchanger and air conditioner, can solve the problem that the air conditioner cannot obtain better heating effect, so as to reduce the impact, ensure the smoothness, and ensure the The effect of thermal effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

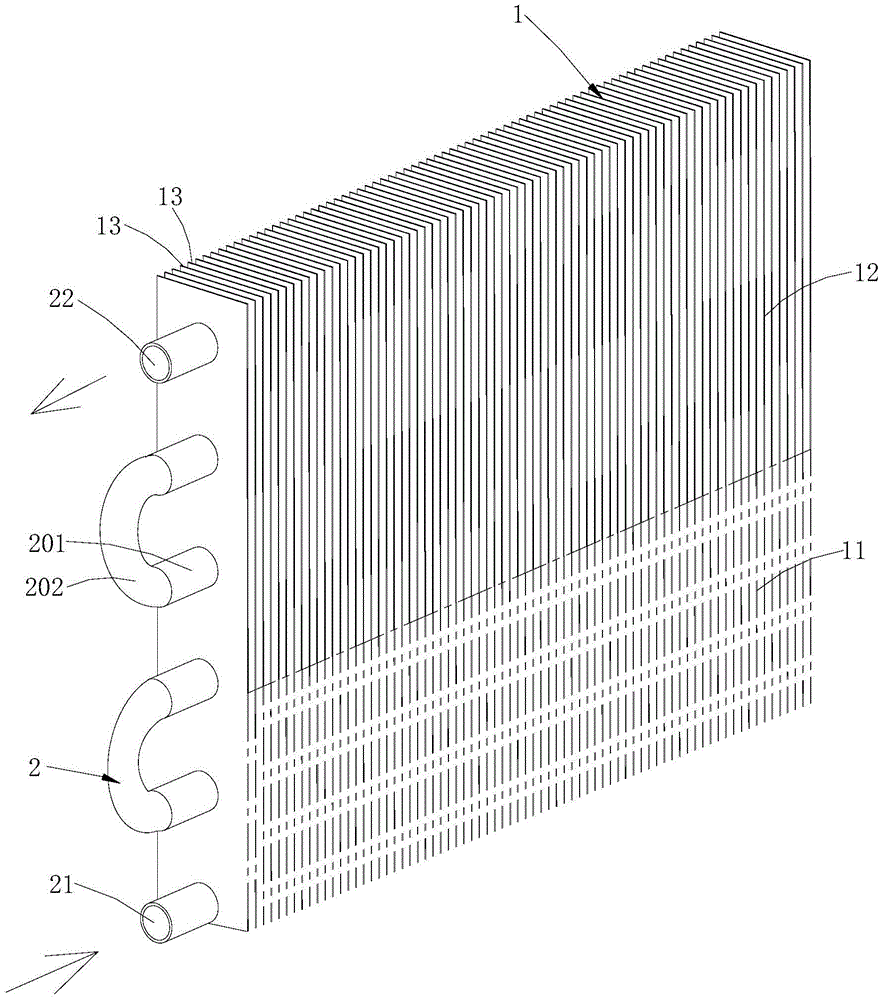

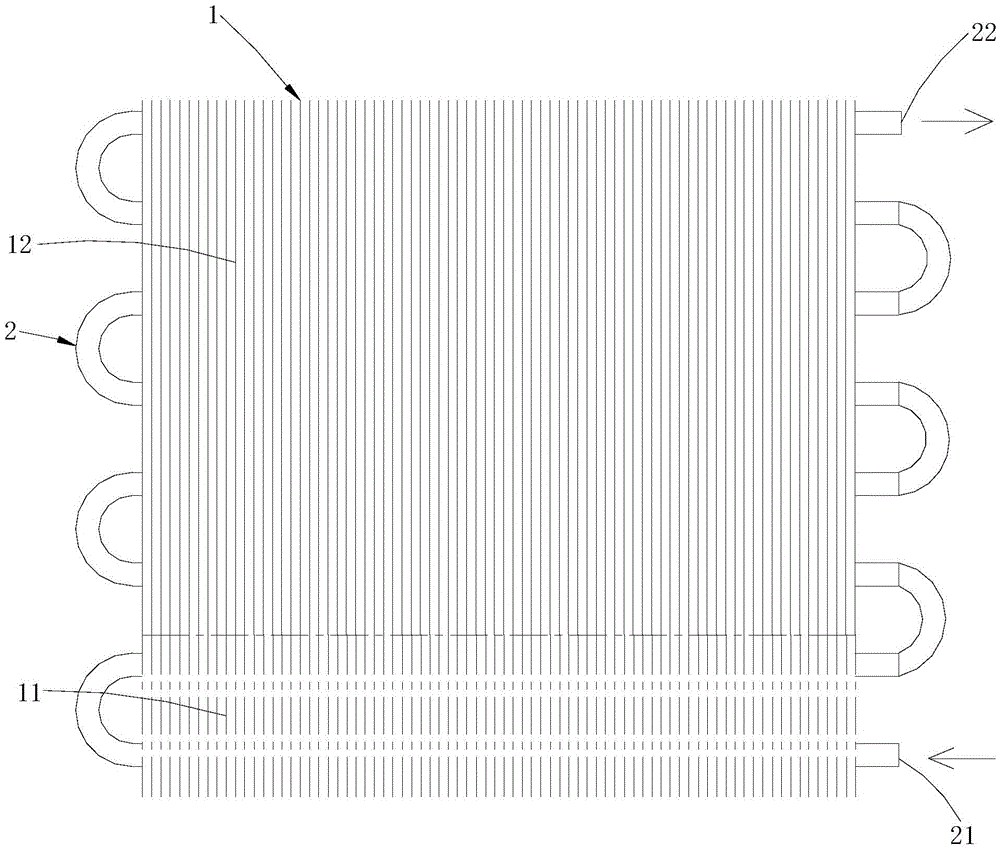

[0034] together with reference figure 1 and figure 2 As shown, in this specific embodiment, the tube-fin heat exchanger is a single-flow heat exchanger, that is, a heat exchanger with only one refrigerant heat exchange process (one-in-one-out heat exchanger), and the first port 21 number, the number of second ports 22 , the number of hydrophilic regions 11 and the number of hydrophobic regions 12 are all one, and the hydrophilic region 11 is located below the hydrophobic region 12 . When the tube-fin heat exchanger is used as an evaporator, the first port 21 is the refrigerant inlet, and the second port 22 is the refrigerant outlet. During the specific heat exchange process, the refrigerant with a lower temperature enters the fin assembly 1 from the first port 21 heat exchange in the hydrophilic area 11 of the fin assembly 1, and then enter the hydrophobic area 12 of the fin assembly 1 for further heat exchange, and finally leave the tube-fin heat exchanger from the second p...

specific Embodiment approach 2

[0036] refer to image 3 As shown, in this specific embodiment, the tube-fin heat exchanger is a multi-process heat exchanger, which has at least two heat exchangers (multi-input and multi-outlet heat exchangers) in parallel refrigerant heat exchange processes, and the first port 21, the number of second ports 22, the number of hydrophilic regions 11 and the number of hydrophobic regions 12 are all the same and at least two, each hydrophobic region 12 and each hydrophilic region 11 are on the fin assembly 1 along it The distribution arrangement direction is alternately distributed from top to bottom. When the tube-fin heat exchanger is used as an evaporator, each first port 21 is a refrigerant inlet, and each second port 22 is a refrigerant outlet. 21 enters the hydrophilic regions 11 of the fin assembly 1 for heat exchange, then enters the hydrophobic regions 12 of the fin assembly 1 for further heat exchange, and finally leaves the tube-fin heat exchanger through the second...

specific Embodiment approach 3

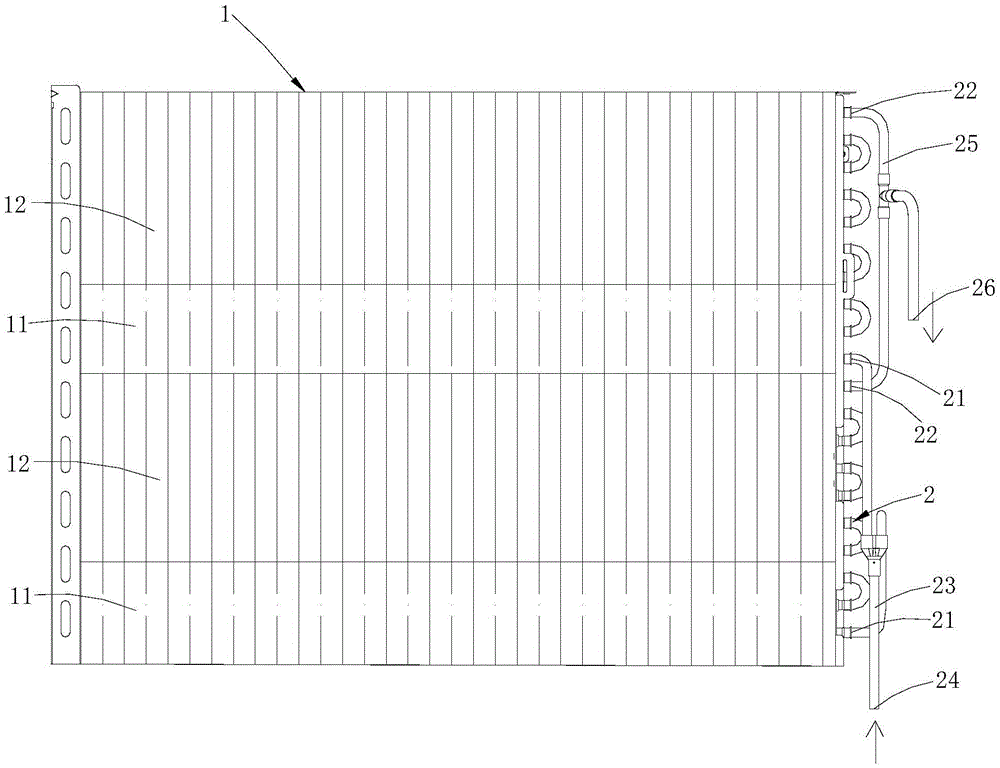

[0041] refer to Figure 4 As shown, in this specific embodiment, the tube-fin heat exchanger is also a multi-pass heat exchanger, but it is different from the above specific embodiment two in that: refer to image 3 As shown, in the second specific embodiment, after the refrigerant enters the tube-fin heat exchanger, it is branched into multiple branches, and then the multiple branches enter different regions of the fin assembly 1 for heat exchange; while referring to Figure 4As shown, in this specific embodiment, after the refrigerant enters the tube-fin heat exchanger, it will first enter a region of the fin assembly 1 for heat exchange, and then branch into multiple branches, and then make the multiple branches respectively enter into other different regions of the fin assembly 1 for heat exchange. Specifically, the number of second ports 22, the number of hydrophilic regions 11 and the number of hydrophobic regions 12 are the same and at least two, the number of first po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com