A Speckle Fabrication Method for Deformation Measurement

A production method and speckle technology, applied in the field of photomechanics, to achieve the effect of easy realization, moderate density and uniform speckle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

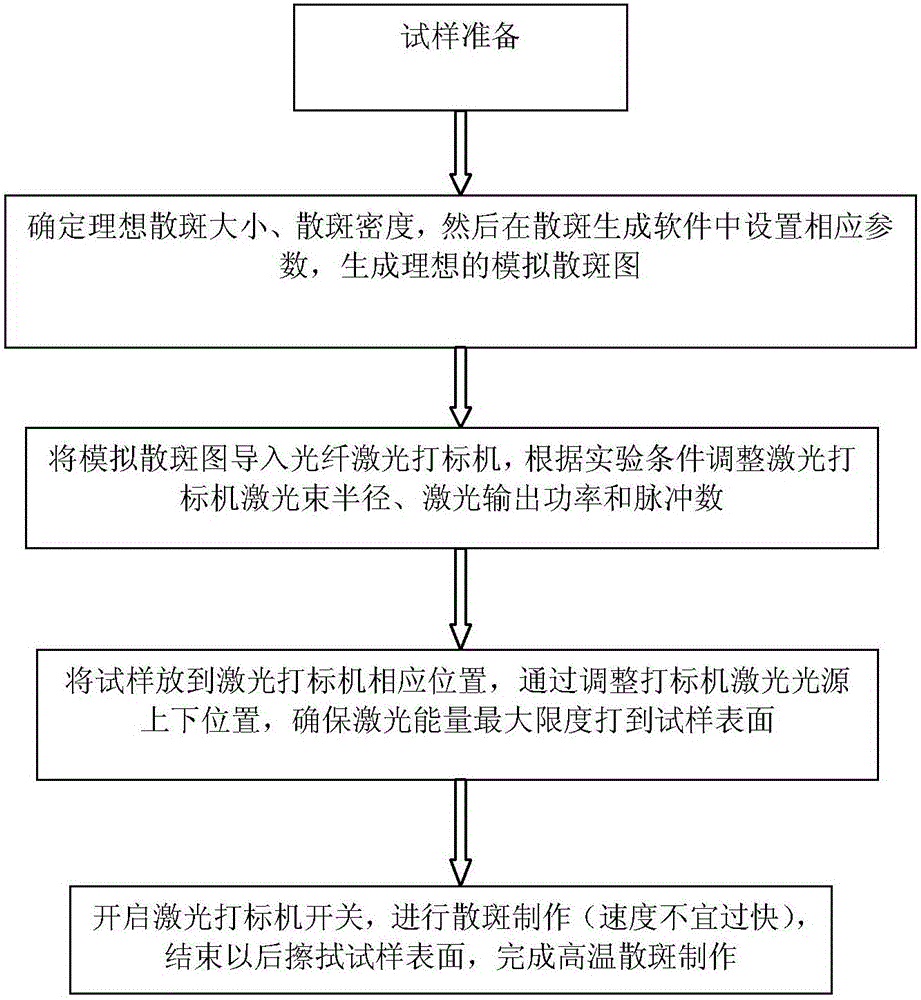

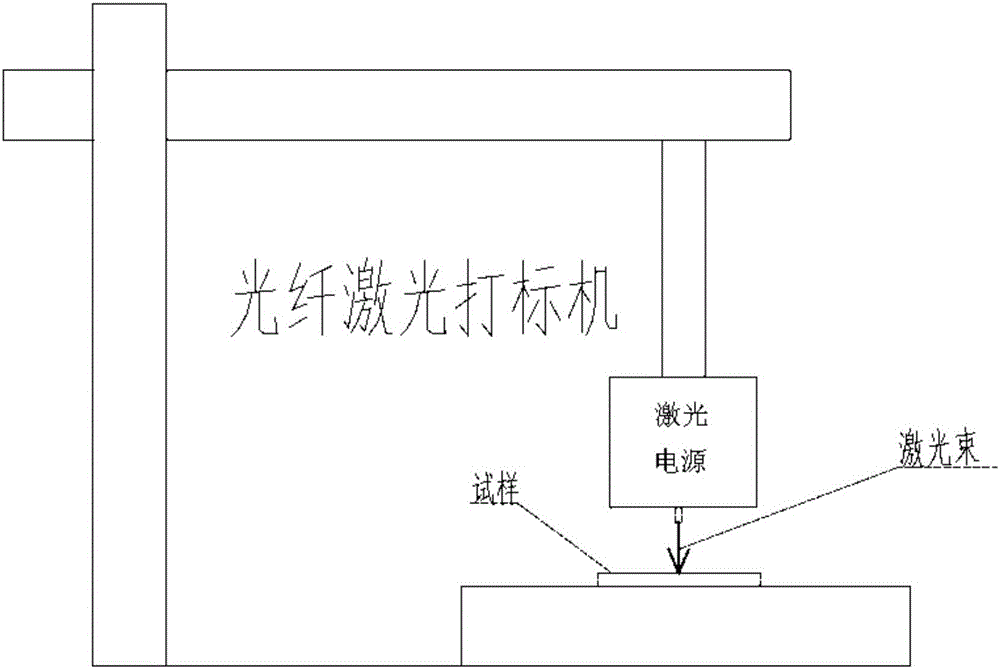

[0018] like figure 1 Operational flowchart of the speckle creation method for deformation measurement shown, figure 2 It is a schematic diagram of speckle production by fiber laser marking machine, and its specific operation steps are as follows:

[0019] a. The material of the tested piece is selected as a pure titanium plate-shaped standard tensile piece (the material grade is Ti6), and the size of the tested piece is 190mm×12.5mm×3mm (length×width×thick) Wipe dry with cotton balls and dry after cleaning;

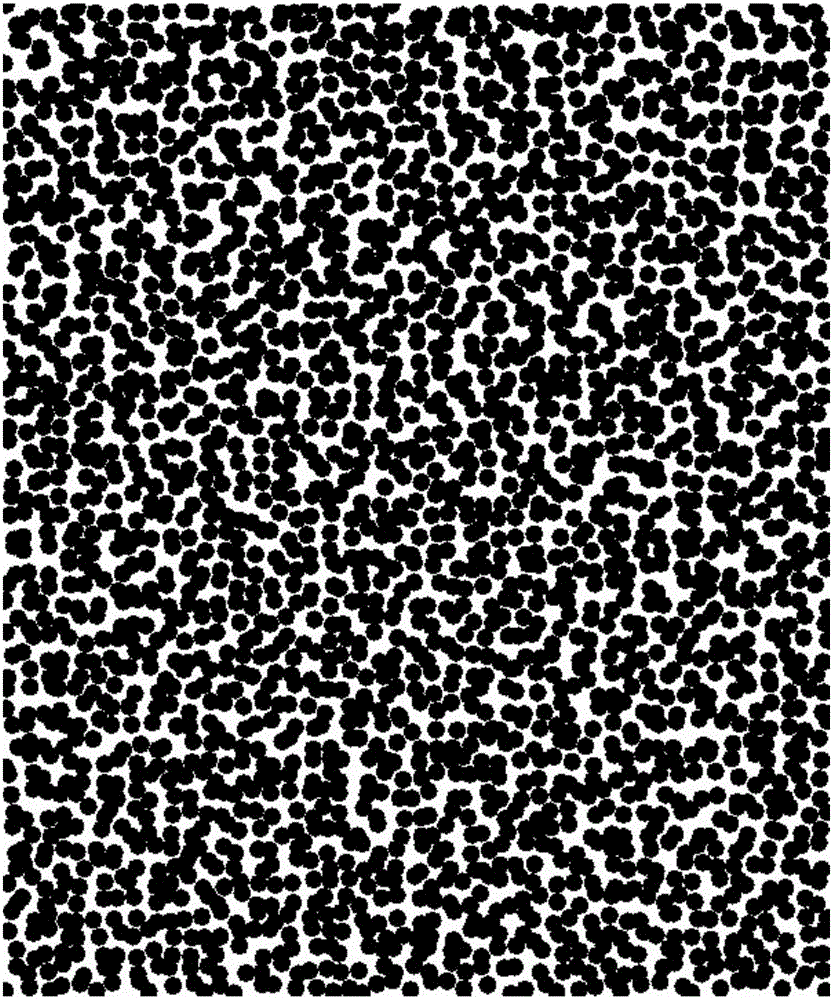

[0020] b. According to the experimental conditions and test requirements, the speckle diameter is determined to be 0.03mm, the speckle density is 85%, and the randomness is 90%. Input the corresponding parameters into the speckle generation software, and export the ideal speckle map (PDF format), such as image 3 The ideal speckle image processed by the speckle generation software shown;

[0021] c. Import the simulated ideal speckle pattern into the fiber laser mark...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com