Method for determining noise source position and noise directivity of high-parameter pressure-reducing valve

A high-parameter pressure reducing valve, noise source location technology, applied in the direction of the system to determine the direction or offset, direction finder using ultrasonic/sonic/infrasonic, beacon system using ultrasonic/sonic/infrasonic, etc., can solve Intense turbulence, high noise, etc., to achieve high computing efficiency, cost savings, and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

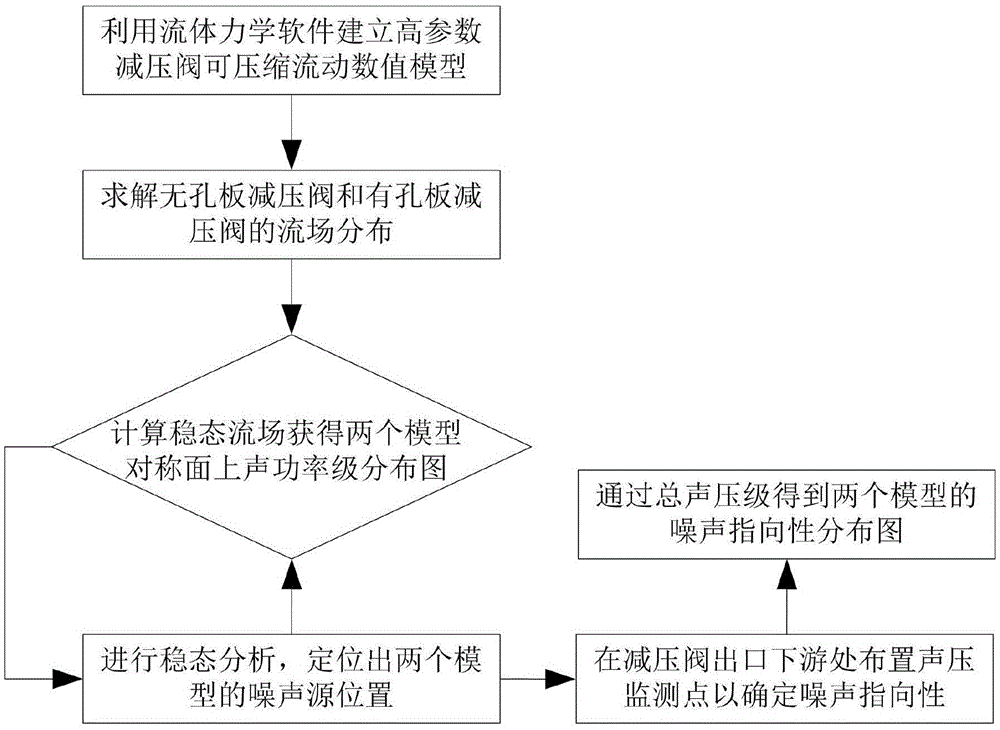

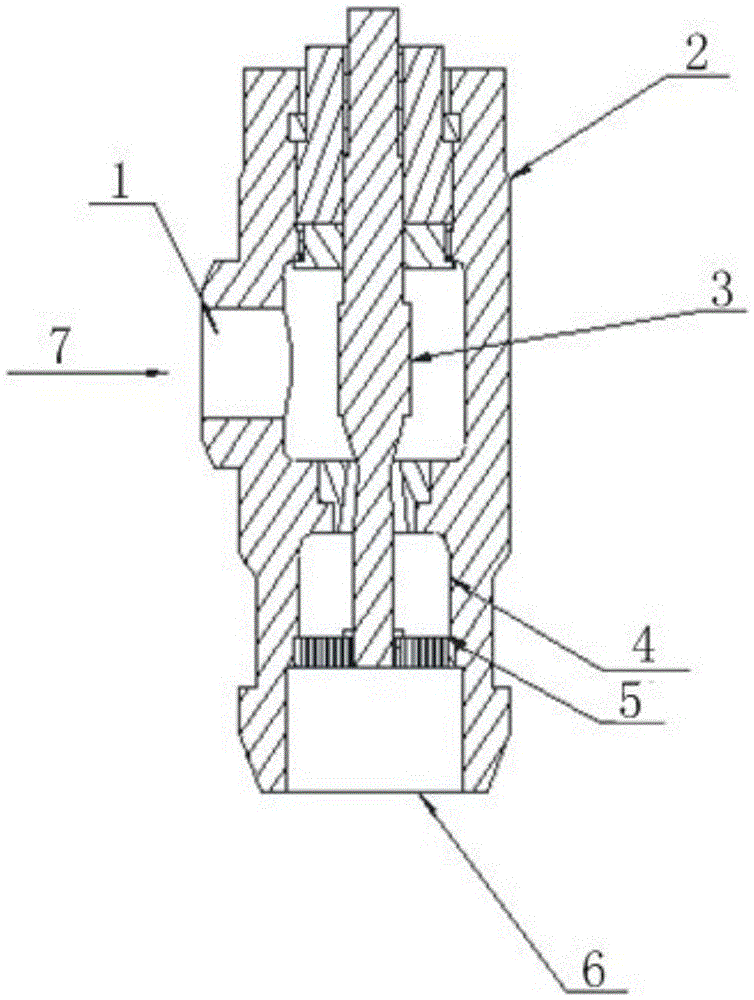

[0031] refer to Figure 1 to Figure 5 , the present invention comprises the following steps:

[0032] (1) Establish a high-parameter compressible flow numerical model of a pressure reducing valve using fluid mechanics software;

[0033] (2) Solve the flow field distribution of the high-parameter pressure reducing valve without orifice plate and the high-parameter pressure reducing valve with orifice plate respectively through the basic control equation or the large eddy simulation turbulence model equation;

[0034] (3) Through the calculation of the steady-state flow field, analyze the flow field distribution of the two models respectively, and compare and analyze the turbulence intensity and the change trend of the Mach number along the streamline of the two models, and obtain the distribution diagram of the sound power level on the symmetrical surface of the two models;

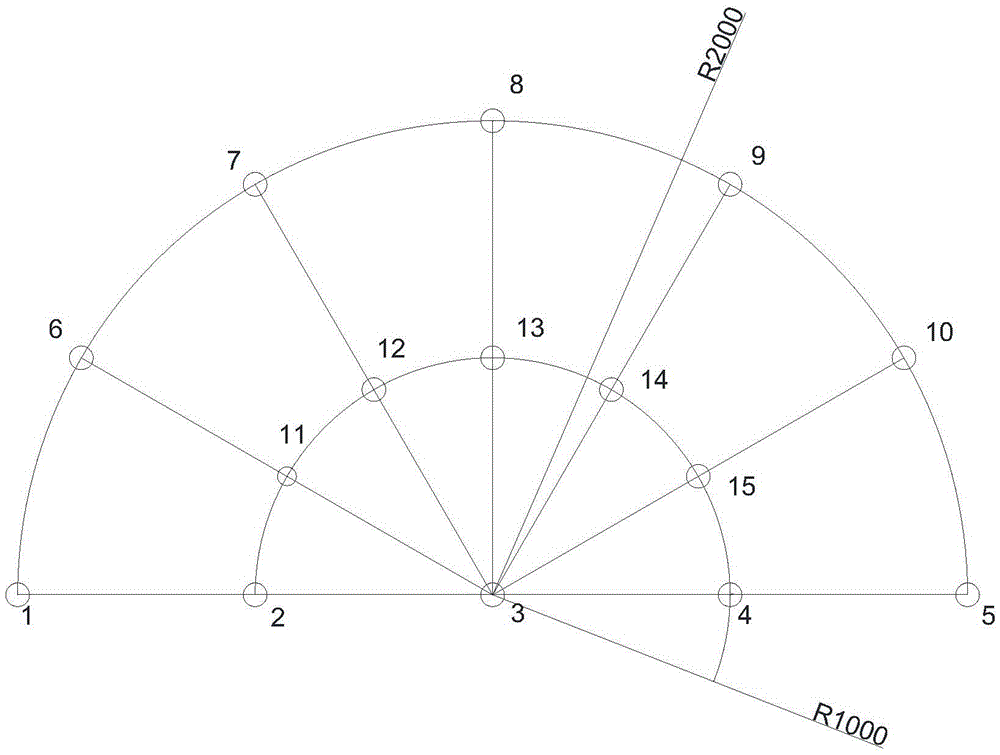

[0035] (4) Steady-state analysis is carried out to locate the noise source positions of the two models...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com