Full dielectric layer twisted glass fiber band nylon optical cable resistant to thunder, mice and ants, and manufacturing method thereof

A manufacturing method and technology of glass fiber tapes, which are applied in the directions of light guide, optics, optical components, etc., can solve the problems of low efficiency of nylon sheath, no anti-rat and anti-term, and damage to optical cables by several bites, and achieve excellent anti-rat performance, High safety and usability, quality improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

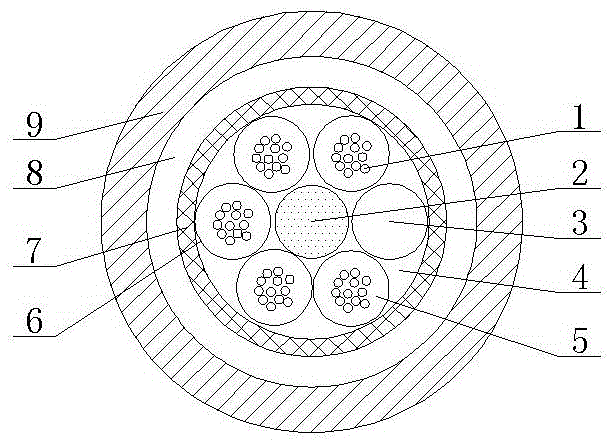

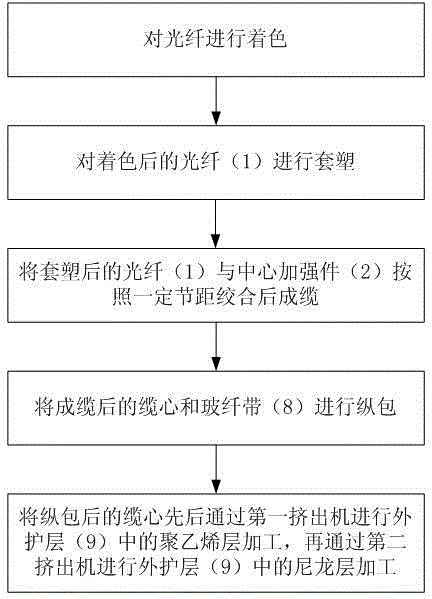

[0031] Such as figure 1 As shown, the all-dielectric stranded glass fiber ribbon nylon lightning-proof, rodent-proof and termite-proof optical cable includes at least one tight-buffered optical fiber, a central strength member 2, a filling rope 3, an inner sheath 7, a glass fiber ribbon 8 and an outer sheath 9 , the tight-buffered optical fiber includes a plurality of optical fibers 1, a loose tube 6 and fiber paste 5, the optical fiber 1 is arranged inside the loose tube 6, and the fiber paste 5 is filled between the optical fiber 1 and the loose tube 6, the fiber paste 5 can not only prevent The impact of water vapor on the optical fiber 1, and can also prevent the optical fiber 1 from stretching naturally in the loose tube 6, so that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com