Device and method for assembling fast reactor MOX components

A component, hexagonal technology, applied in the field of reactor engineering, to achieve the effect of simple assembly, improved pick-and-place efficiency, and easy manual operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further elaborated below in conjunction with the specific embodiments and the accompanying drawings.

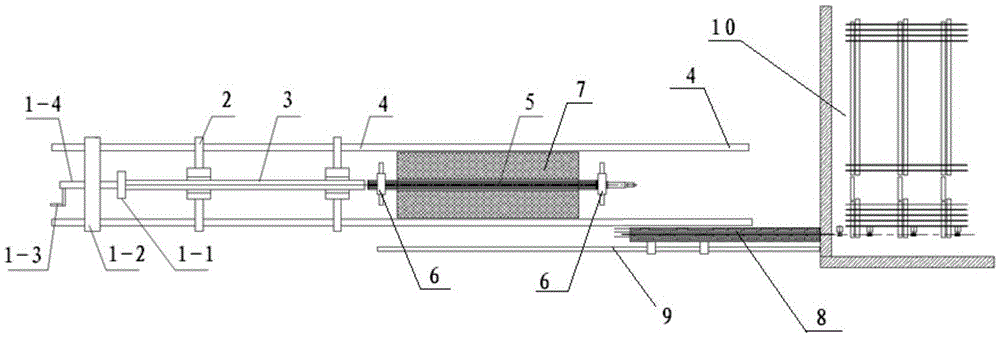

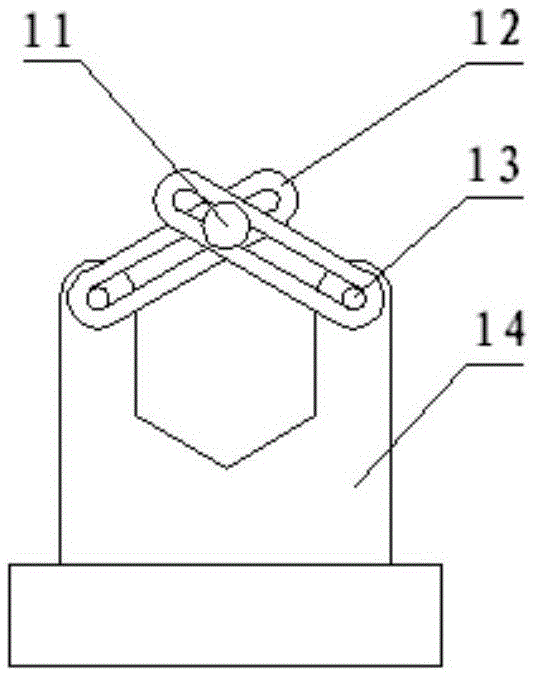

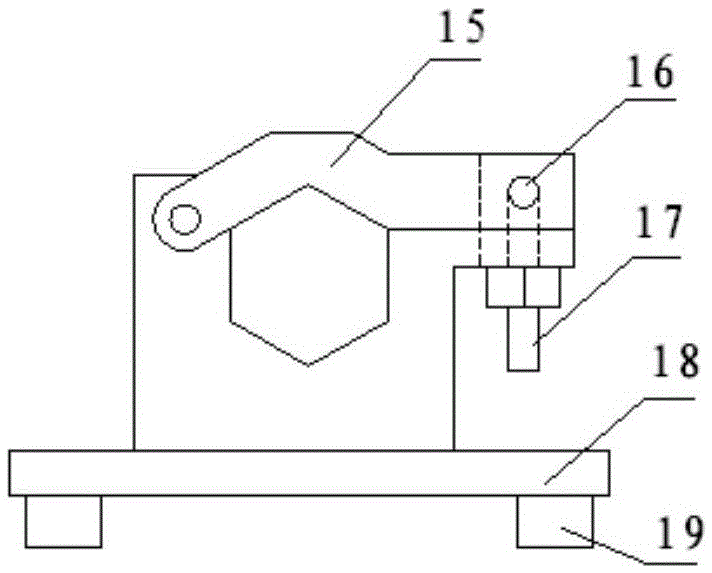

[0035] A device for assembling fast reactor MOX components such as Figure 1 ~ Figure 4 As shown, the device includes an assembly platform and a hexagonal outer sleeve clamp 2 located on the assembly platform, a hexagonal outer sleeve support, a hexagonal outer sleeve 3, a rod bundle bracket 6, a component shield 7 and a fuel rod shield 8, Wherein the hexagonal outer casing fixture 2 and the assembly shielding body 7 are located in the first guide rail 4 of the assembly platform, and the hexagonal outer casing fixture 2 moves horizontally through the first guide rail 4; the fuel rod shielding body 8 is located on the second rail below the assembly shielding body 7 On the guide rail 9, it can be moved horizontally, and the side of the fuel rod shield 8 is provided with a groove to facilitate the removal of the fuel rod; the component shield...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com