IGBT drive protective circuit board

A technology for driving protection circuits and PCB circuit boards, which is applied to emergency protection circuit devices, printed circuit components, electrical components, etc. It can solve the problems that components cannot be replaced separately, IGBT protection is not possible, and IGBT is easily damaged, so as to improve heat dissipation. effect, IGBT damage prevention, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

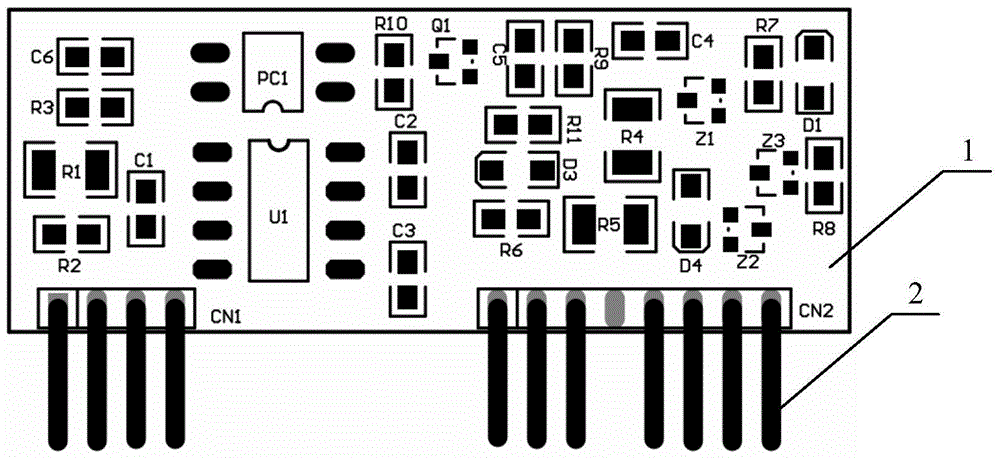

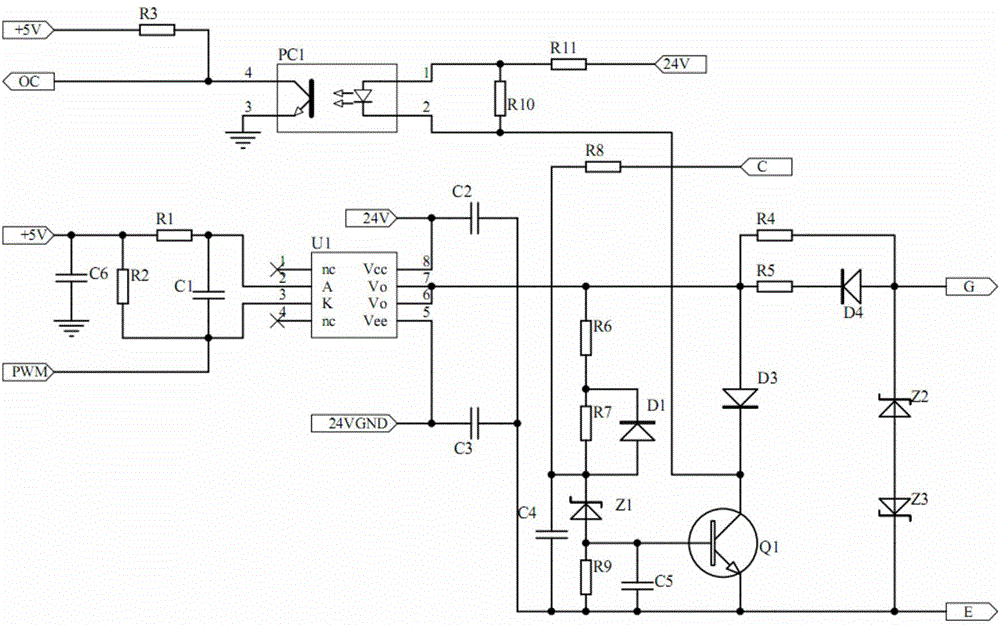

[0017] A kind of IGBT drive protection circuit board that the present invention proposes, as shown in the figure, it comprises PCB circuit board substrate 1 and the drive protection circuit that is integrated on the printed surface of PCB circuit board substrate 1 in patch mode, and drive protection circuit is driven by Composed of a circuit module, a protection circuit module and a feedback circuit module, the drive circuit module is provided with a first positive 5V voltage input terminal, a pulse signal input PWM terminal, a first ground terminal, a first positive 24V voltage input terminal, and a negative 24V voltage input terminal. Access terminal, IGBT grid connection terminal G and IGBT emitter connection terminal E, the protection circuit module is provided with an IGBT collector connection terminal C, and the feedback circuit module is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com