Group-III nitride semiconductor epitaxial substrate, group-III nitride semiconductor light-emission element, and production method for these

A technology of nitride semiconductors and epitaxial substrates, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, semiconductor lasers, etc., can solve problems such as lattice constants, different thermal expansion coefficients, large strains, and difficulty in obtaining atomic-level surface flatness. Achieves the effect of suppressing crack generation and excellent surface flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0095] (trial example 1)

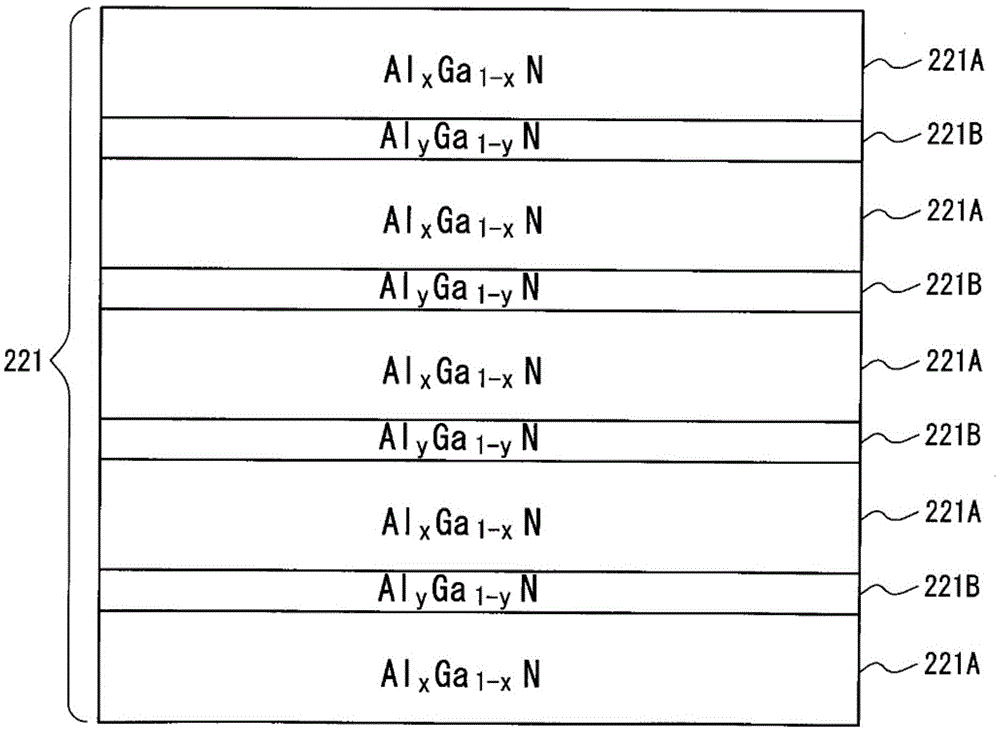

[0096] AlN prepared to form an undoped AlN layer (thickness: 600nm, half-value width of the AlN (102) plane according to XRC (X-ray rocking curve; X-ray Rocking Curve): 242 seconds) on a sapphire substrate (thickness: 430 μm) template substrate. Using the MOCVD method on this AlN template substrate, flow TMA: 11.5 sccm, NH at a pressure of 10kPa and a temperature of 1150°C 3 : 575sccm After forming a non-doped AlN layer with a thickness of 21.6nm, flow TMA: 11.5sccm, NH 3 : 575 sccm, SiH 4 : 50sccm, forming an impurity concentration of 2.0×10 19 / cm 3 Si-doped AlN buffer layer with a thickness of 5.4 nm. That is, an undoped AlN layer and a Si-doped AlN buffer layer are formed on an AlN template substrate. That is, when the sum of the layer thicknesses of the undoped AlN layer and the Si-doped AlN buffer layer on the AlN template substrate is 27 nm, the Si-doped thickness is 5.4 nm. Next, the first stacked body, the second stacked body, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap