Method for producing color filter, color filter and liquid crystal display panel

一种彩色滤光片、光束的技术,应用在滤光片、光学、光学元件等方向,能够解决彩色滤光片的色阻层表面平坦度不佳、导电膜易发生破裂等问题,达到减小牛角现象、改善易发生破裂、提高表面平坦度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

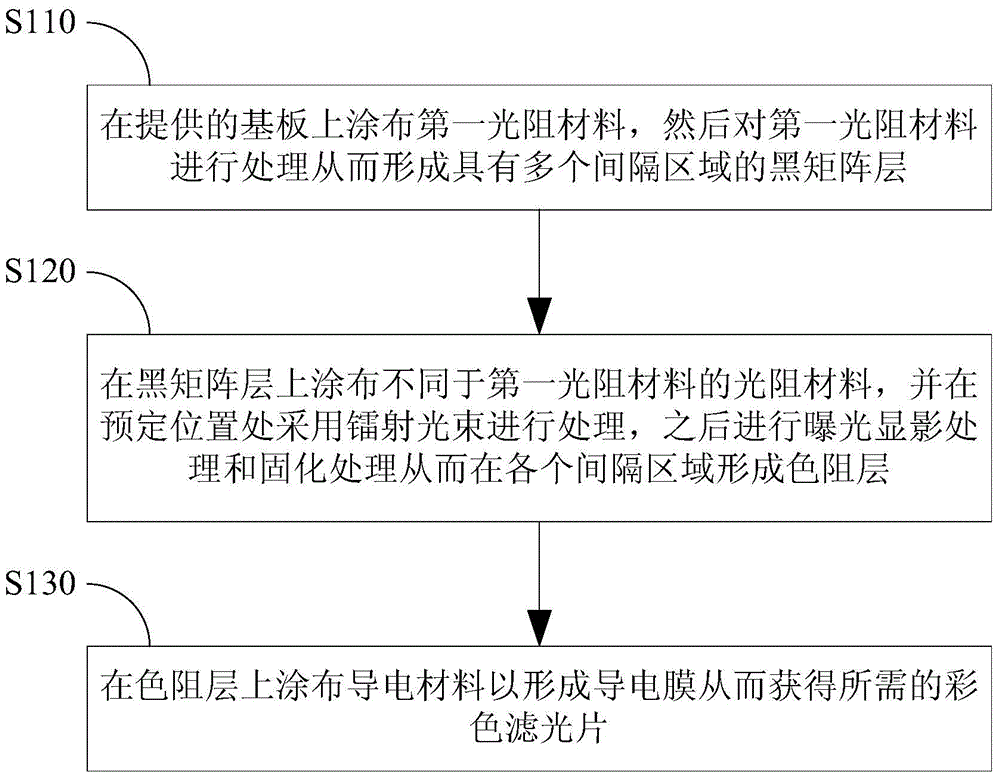

[0030] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings and examples, so as to fully understand and implement the process of how to apply technical means to solve technical problems and achieve technical effects in the present invention. It should be noted that, as long as there is no conflict, each embodiment and each feature in each embodiment of the present invention can be combined with each other, and the formed technical solutions are all within the protection scope of the present invention.

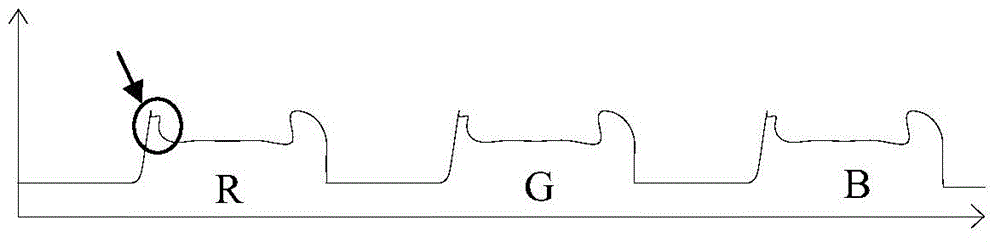

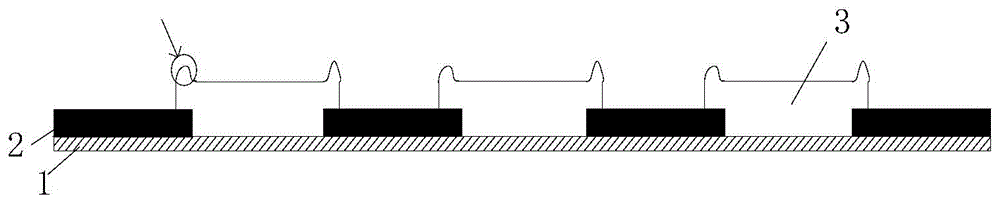

[0031] At present, the manufacturing process of color filters mainly includes the following steps: first, a black matrix layer is formed on the substrate; then, color-resist materials (which belong to photoresist materials) are sequentially coated on the black matrix layer and correspondingly carried out respectively. Exposure, development, and curing are performed to form a corresponding color-resist layer; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com