Method for manufacturing sic single-crystal substrate for epitaxial sic wafer, and sic single-crystal substrate for epitaxial sic wafer

A technology of silicon carbide single crystal and epitaxial silicon carbide, which is applied in the direction of chemical instruments and methods, manufacturing tools, single crystal growth, etc., can solve problems such as difficult to deal with large devices, low epitaxial defect density, etc., and achieve characteristics and yield improvement, Excellent reproducibility and excellent surface flatness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

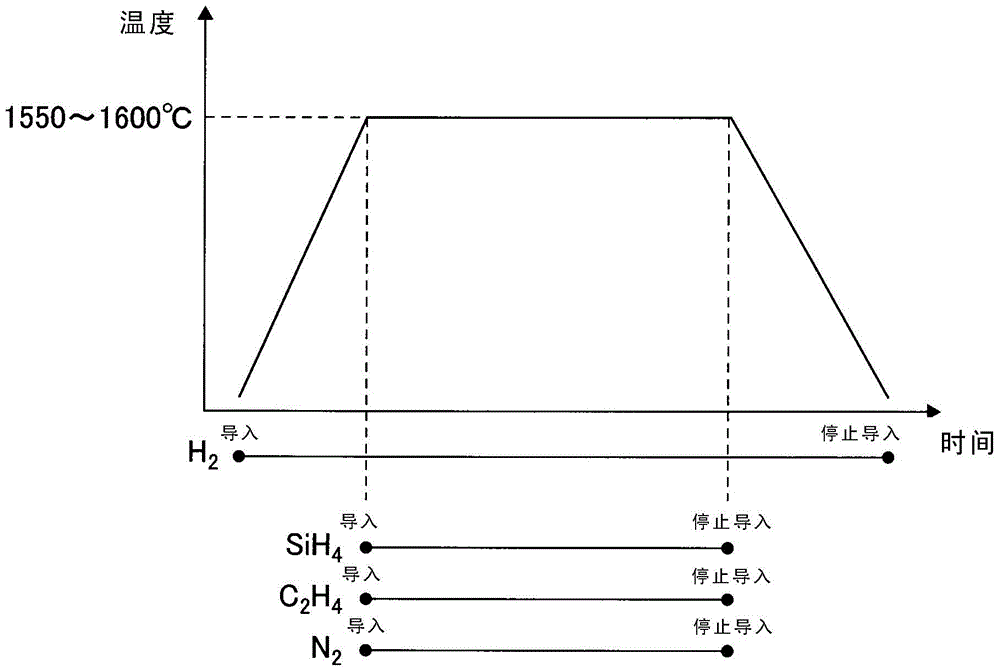

Method used

Image

Examples

Embodiment 1

[0043] A 4-inch (100 mm) wafer is cut from a SiC single-crystal ingot with a thickness of about 400 μm, and subjected to grinding and normal polishing with diamond abrasive grains to prepare a substrate to be subjected to CMP. The polytype of this substrate is 4H type with an off angle of 4°. When polishing is performed in this way, the thickness of the processing-altered layer on the surface is about 100 nm or less. Next, perform CMP as follows.

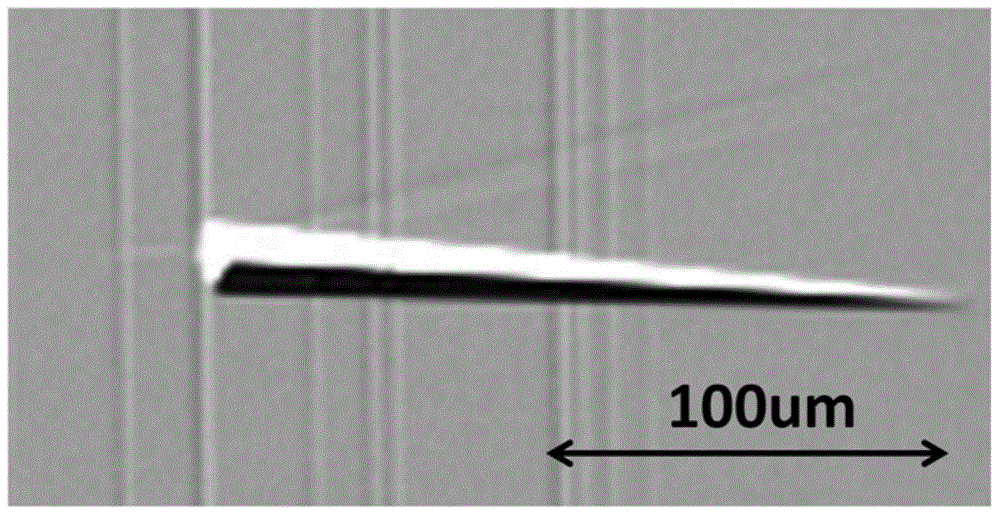

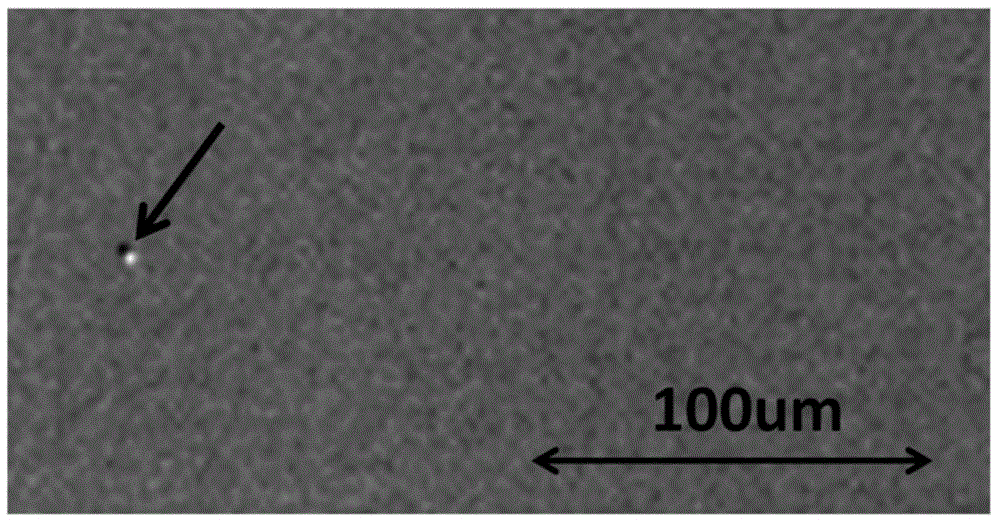

[0044] As the polishing slurry, a slurry containing abrasive particles such as silicon dioxide and an acid is used, the processing pressure and the pH of the slurry are appropriately adjusted, and the polishing rate is 100 nm / hour, and the surface of the substrate is removed to a thickness of 100 nm ( The amount of polishing is 100 nm), and CMP is performed so that no polishing marks remain. After the completion of CMP, the pits on the surface of the SiC substrate obtained in this example were observed using a confocal microscope ...

Embodiment 2

[0048] A SiC substrate of Example 2 was obtained in the same manner as in Example 1, except that the CMP polishing rate was 80 nm / hour and the polishing amount was 100 nm. On the surface of the SiC substrate after CMP, the density of approximately circular pits with a diameter of 0.5 μm to 1.5 μm and a depth of 50 nm to 500 nm is 0.6 pits / cm 2 . Next, epitaxial growth was carried out in the same manner as in Example 1, and the number of defects in the grown epitaxial film was evaluated. As a result, the carrot-shaped defect density was 0.8 defects / cm 2 , the density of all epitaxial defects including triangle defects and comet defects is 1.7 / cm 2 .

Embodiment 3

[0050] A SiC substrate of Example 3 was obtained in the same manner as in Example 1, except that the CMP polishing rate was 50 nm / hour and the polishing amount was 100 nm. On the surface of the SiC substrate after CMP, the density of approximately circular pits with a diameter of 0.5 μm to 1.5 μm and a depth of 50 nm to 500 nm is 0.4 pits / cm 2 . Next, epitaxial growth was carried out in the same manner as in Example 1, and the number of defects in the grown epitaxial film was evaluated. As a result, the carrot-shaped defect density was 0.6 defects / cm 2 , the density of all epitaxial defects including triangle defects and comet defects is 1.4 / cm 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com