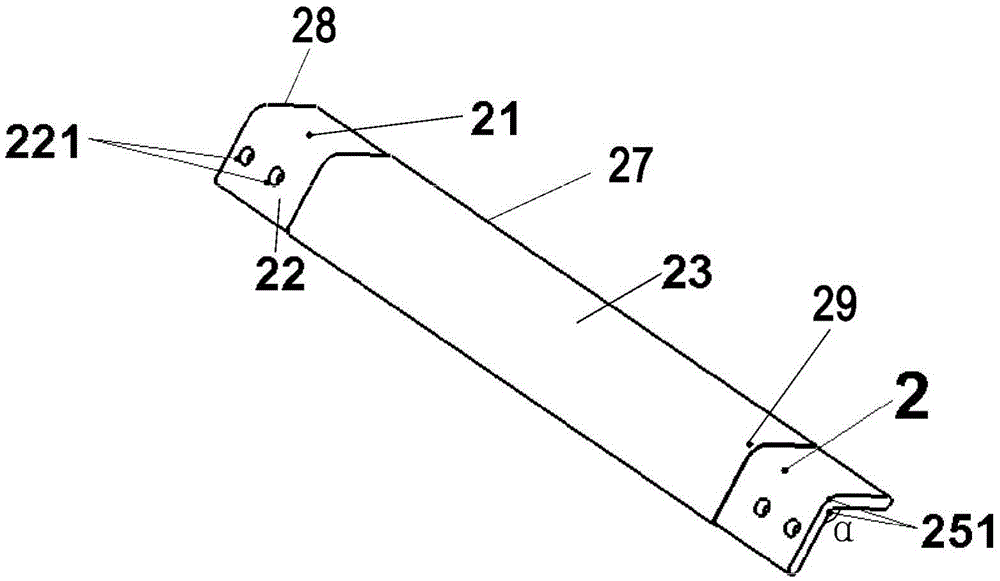

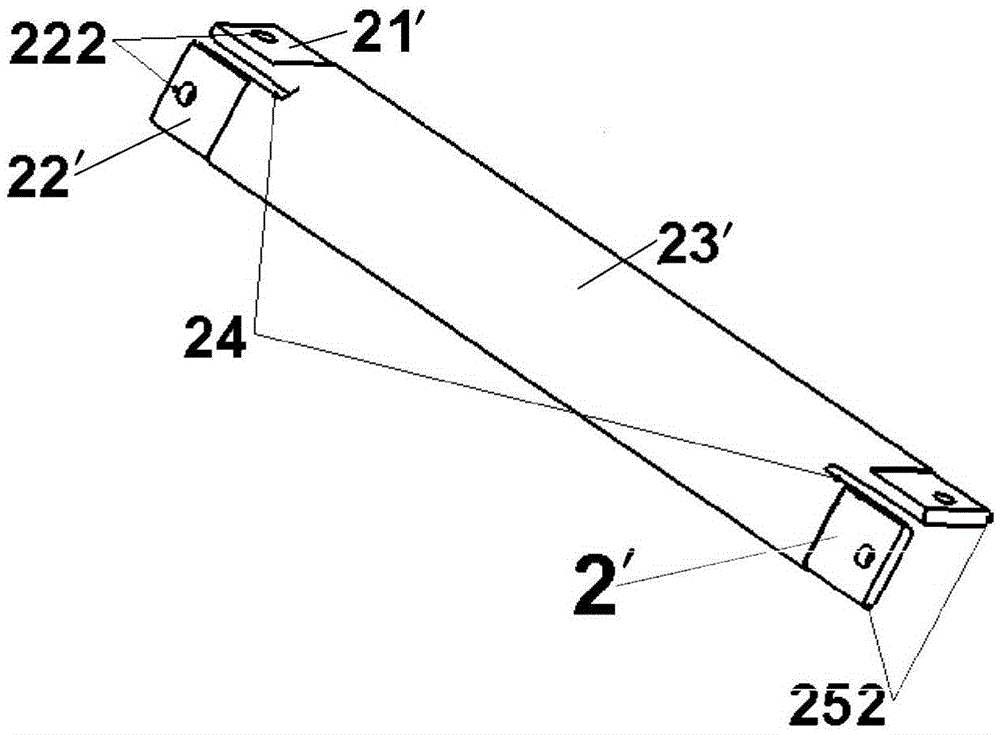

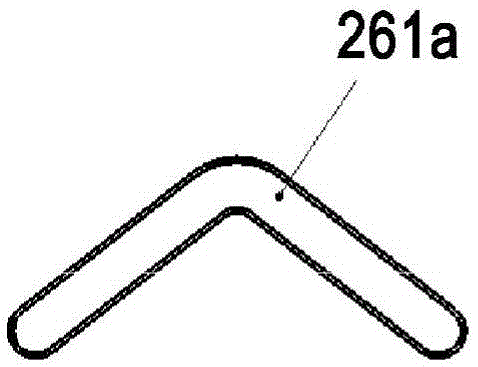

Main bus-bar, branch bus-bar, transfer connector and bus-bar assembly

A technology of branch busbar and main busbar, applied in busbar installation, cooling busbar device, open busbar installation, etc., to achieve the best dynamic stability, good space electric field, and best mechanical bending strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Hereinafter, embodiments of the present disclosure will be described more specifically with reference to the above drawings. It should be understood that these embodiments are presented only to enable those skilled in the art to better understand and implement the present disclosure, and are not intended to limit the scope of the present disclosure in any way.

[0055] Generally, all terms used in the claims are to be interpreted according to their ordinary meaning in the technical field, unless explicitly defined otherwise herein. References to "a / the / said [element, device, part, means, step, etc.]" are to be construed openly as referring to at least one instance of said element, device, part, means, step, etc., rather than A plurality of such devices, components, means, units, steps etc. is excluded unless expressly defined otherwise. Furthermore, the indefinite article "a" as used herein does not exclude a plurality of such steps, units, modules, devices and objects...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com