A hydration reactor and a method for separating methane in air-mixed coalbed methane using the reactor

A hydration reactor and coal bed gas technology, applied in chemical methods, chemical instruments and methods, and gas fuels for reacting liquid and gaseous media, can solve problems such as explosions, achieve operational safety, avoid explosion hazards, and are feasible strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0036] Hydrate working fluid is tetrabutylammonium bromide (English abbreviation: TBAB), and its concentration is 10wt%;

[0037] The composition of mixed gas is shown in Table 1 below:

[0038] Table 1 Composition of air-mixed coalbed methane

[0039] composition

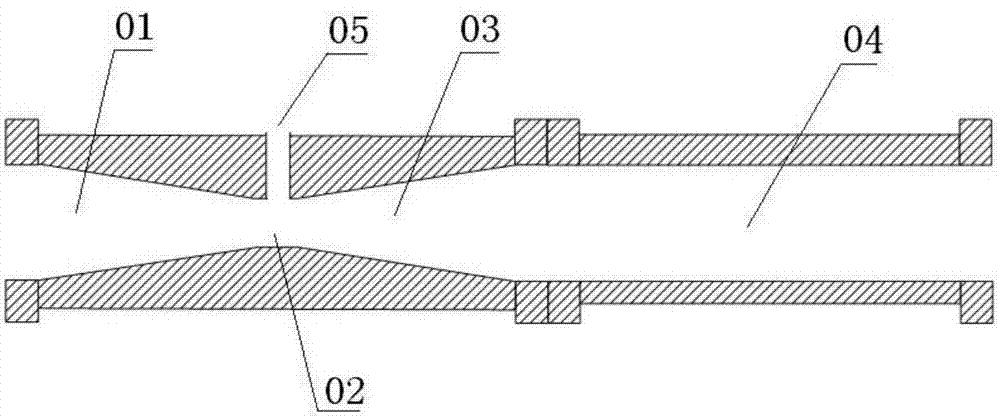

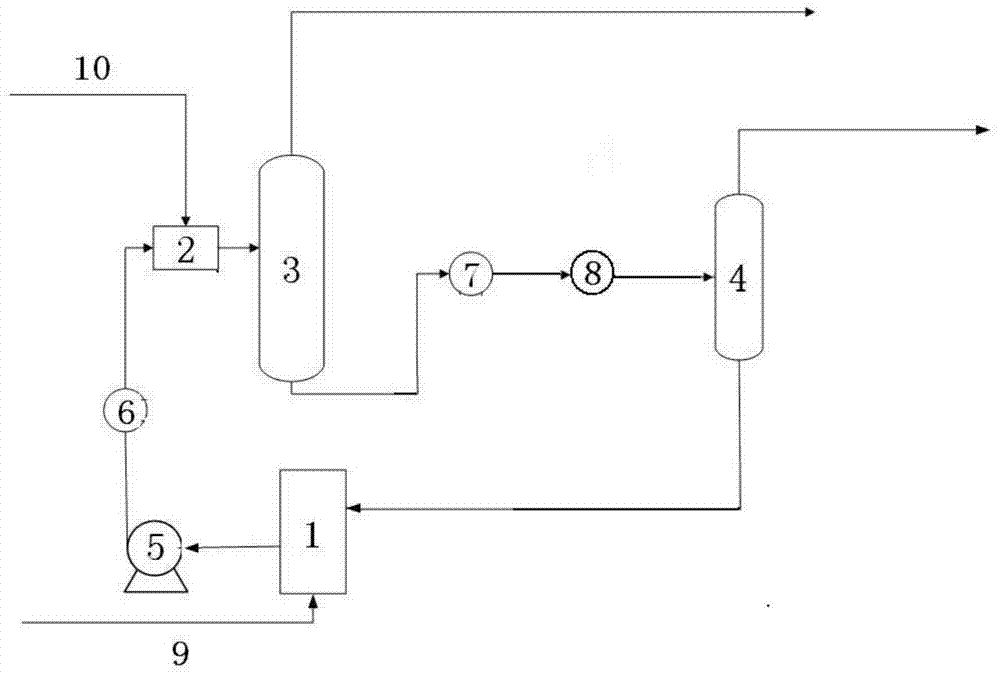

[0040] use as figure 1 The shown hydration reactor separates the methane in the air-mixed coalbed methane. For the specific separation method, please refer to the description of the above separation method. The process parameters involved are as follows:

[0041] 1) The pressure of mixed air CBM is 0.5MPa.

[0042] 2) Hydrate Working Fluid The temperature of the hydrate working fluid entering the hydration reactor is 8°C and the pressure is 3.0MPa.

[0043] 3) The pressure of the hydrate working fluid passing through the throat of the hydration reactor is 0.4MPa.

[0044] 4) The pressure of the fluid formed by the hydrate working fluid and the methane in the mixed gas in the stable section of the hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com