Ground cleaning device

A ground cleaning and cleaning mechanism technology, applied to manual floor scrubbing machines, carpet cleaning, floor cleaning, etc., can solve problems such as manual learning, high use costs, difficult cleaning and maintenance work, and untimely cleaning of the ground to achieve improved reliability. Maintenance effect, good wiping effect, and effect of improving use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

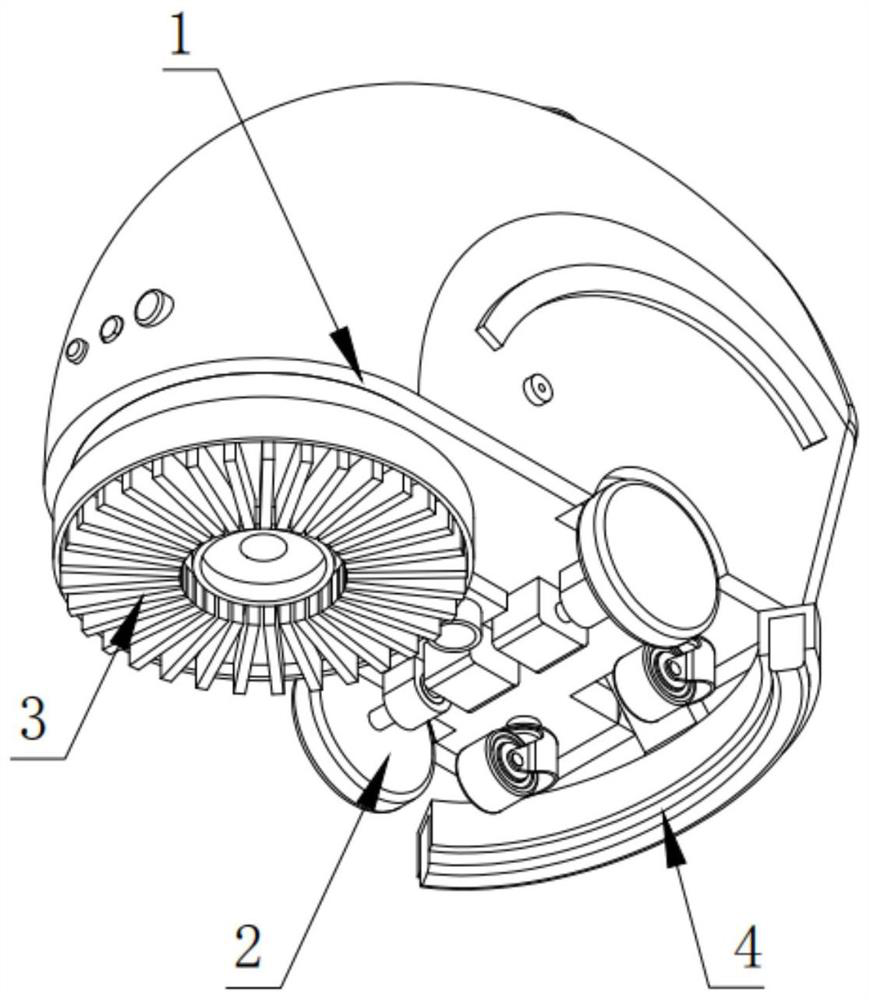

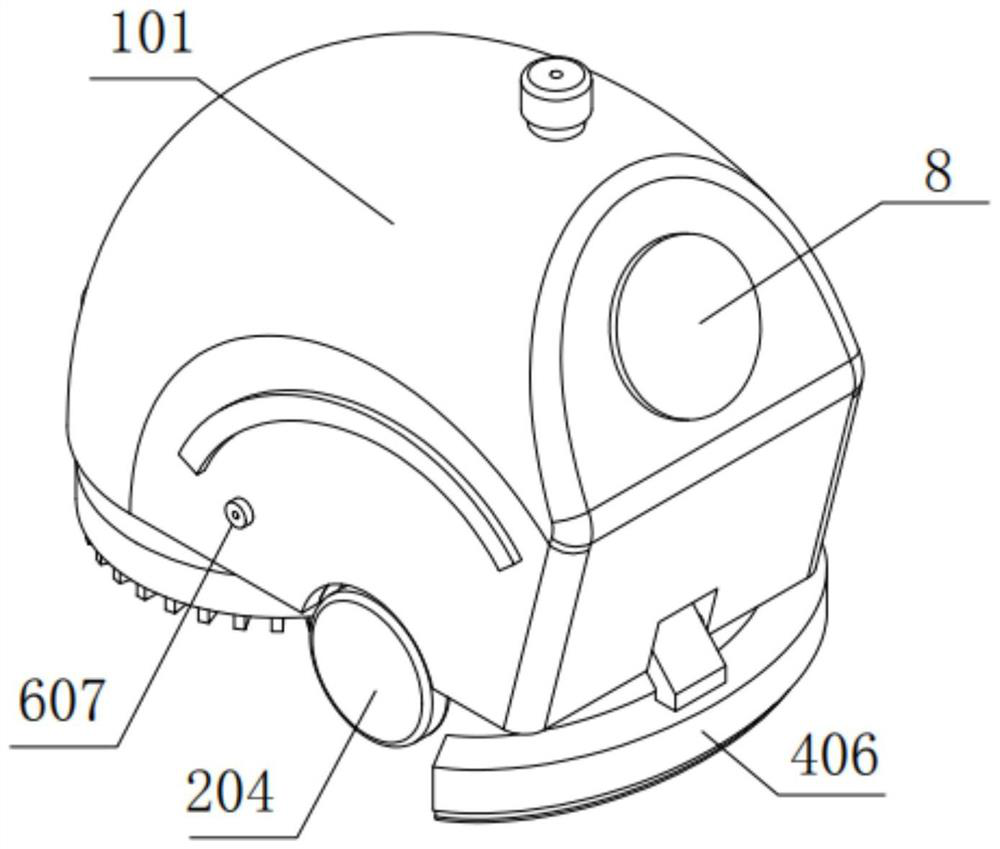

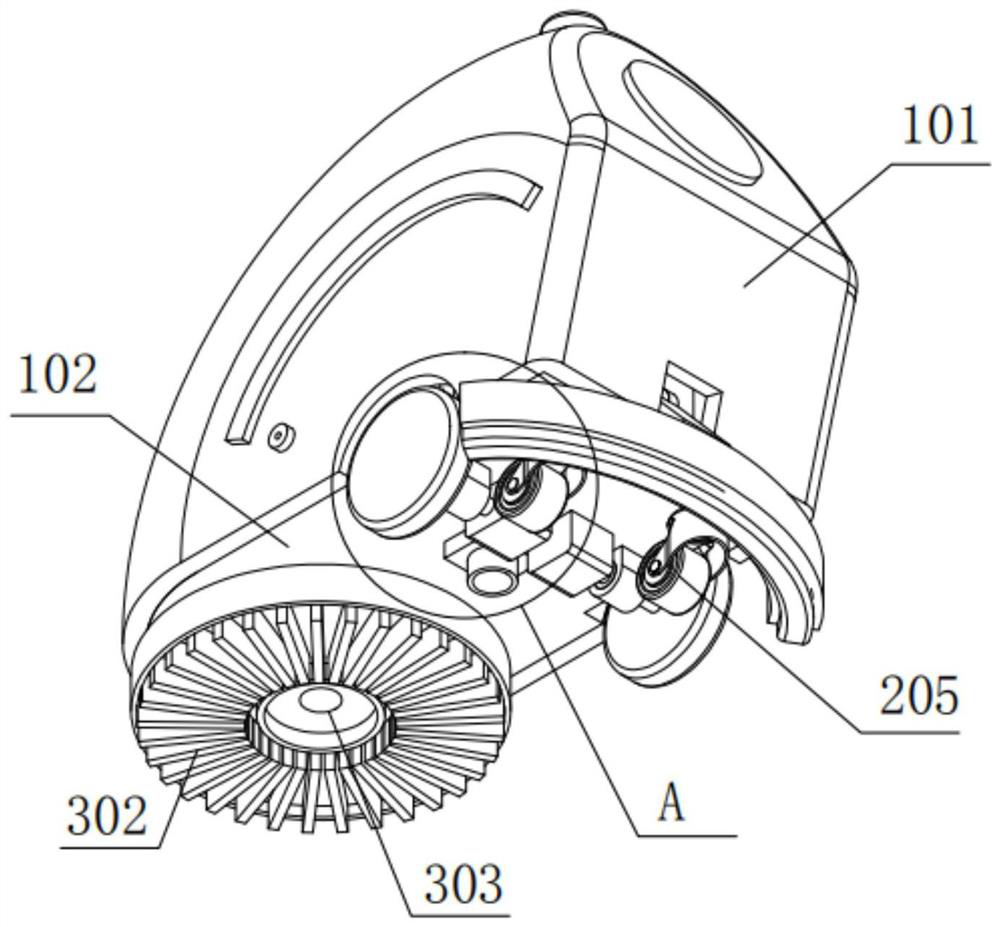

[0036] A floor cleaning device, such as Figure 1~6 As shown, it includes a main structure 1, a cleaning mechanism 3, a wiping mechanism 4, a waste collection mechanism 5, a water spray mechanism 6, a control mechanism 7, and two walking mechanisms 2 for driving the main structure 1, and the main structure 1 includes a housing 101 And the base plate 102 that is fixedly installed on the bottom of the shell 101, the running gear 2 is provided with two groups, the two running gears 2 are installed symmetrically on the bottom of the base plate 102, the cleaning mechanism 3 is installed on one end of the base plate 102, and the wiping mechanism 4 is installed on the other end of the base plate 102. At one end, the waste collection mechanism 5 and the water spray mechanism 6 are installed on the top of the base plate 102, the waste collection mechanism 5 is connected with the cleaning mechanism 3, the control mechanism 7 is installed on the bottom plate 102, and the control mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com