Method for preparing sulfuric acid by utilizing zinc-containing wastewater and NaHS waste liquor in viscose fiber factory

A viscose fiber and waste water technology, applied in chemical instruments and methods, hydrogen sulfide, sulfur compounds, etc., can solve the problems of high cost of waste water treatment, waste of resources, ineffective utilization of zinc-containing waste water and NaHS waste liquid, etc., and achieve a solution Effects of high treatment cost, improved conversion rate, important environmental protection significance and practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

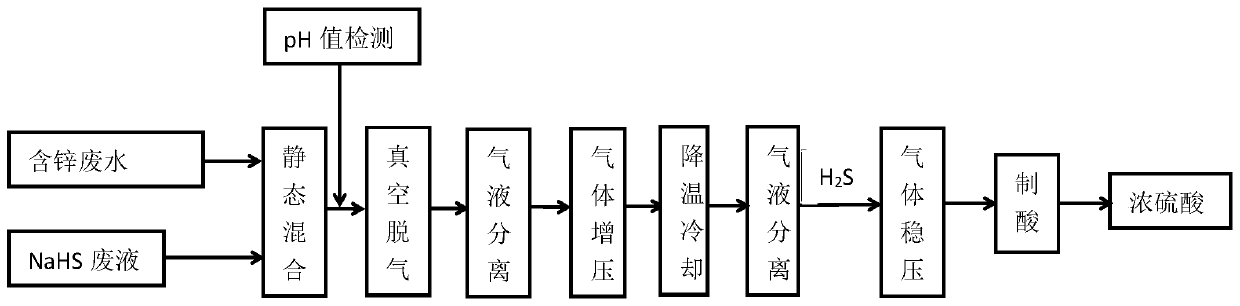

[0035] Such as figure 1 Shown, a kind of method of utilizing viscose fiber factory zinc-containing waste water and NaHS waste liquid of the present invention to prepare sulfuric acid comprises the following steps carried out in sequence:

[0036] (1) Mixing of zinc-containing waste water and NaHS waste liquid

[0037] The zinc-containing wastewater and the NaHS waste liquid are uniformly mixed and reacted according to the hourly volume flow ratio of 70:1, and the pH value of the mixed reaction system is controlled at 3.5; wherein the zinc-containing wastewater is produced in the production of viscose fiber Zinc-containing wastewater, the NaHS waste liquid is the treatment of H in viscose fiber production 2 The NaHS waste liquid that S gas produces; This zinc-containing waste water comprises the NaSO of mass percent 3% 4 , 1.5% H by mass 2 SO 4 and 0.1% by mass of ZnSO 4 ; NaHS waste liquid comprises the NaHS of mass percentage 21% and the Na of mass percentage 1.8% 2 S; ...

Embodiment 2

[0047] Such as figure 1 Shown, a kind of method of utilizing viscose fiber factory zinc-containing waste water and NaHS waste liquid of the present invention to prepare sulfuric acid comprises the following steps carried out in sequence:

[0048] (1) Mixing of zinc-containing waste water and NaHS waste liquid

[0049] The zinc-containing wastewater and the NaHS waste liquid are uniformly mixed and reacted according to the hourly volume flow ratio of 60:1, and the pH value of the mixed reaction system is controlled at 3; wherein the zinc-containing wastewater is produced in the production of viscose fiber Zinc-containing wastewater, the NaHS waste liquid is the treatment of H in viscose fiber production 2 The NaHS waste liquid that S gas produces; This zinc-containing waste water comprises the NaSO of mass percent 1.5% 4 , mass percentage 2% H 2 SO 4 and 0.05% by mass of ZnSO 4 ; NaHS waste liquid comprises the NaHS of mass percentage 23% and the Na of mass percentage 1% ...

Embodiment 3

[0059] Such as figure 1 Shown, a kind of method of utilizing viscose fiber factory zinc-containing waste water and NaHS waste liquid of the present invention to prepare sulfuric acid comprises the following steps carried out in sequence:

[0060] (1) Mixing of zinc-containing waste water and NaHS waste liquid

[0061] The zinc-containing wastewater and the NaHS waste liquid are uniformly mixed and reacted according to the hourly volume flow ratio of 80:1, and the pH value of the mixed reaction system is controlled at 4; wherein the zinc-containing wastewater is produced in the production of viscose fiber Zinc-containing wastewater, the NaHS waste liquid is the treatment of H in viscose fiber production 2 The NaHS waste liquid that S gas produces; This zinc-containing waste water comprises the NaSO of mass percent 3.5% 4 , 0.5% H by mass 2 SO 4 and 0.15% by mass of ZnSO 4 ; The NaHS waste liquid of present embodiment comprises the NaHS of mass percentage 18% and the Na of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com