Fully automatic ultrasonic integrated cleaning machine for double-layer turbocharger housing parts

A turbocharger and ultrasonic technology, applied in the field of parts cleaning, can solve the problems of low efficiency of cleaning process, complex structure and shape of turbocharger, and no recycling or disposal of cleaning fluid, so as to improve cleaning quality and cleaning efficiency, reduce The effect of expanding the area horizontally and improving the area utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

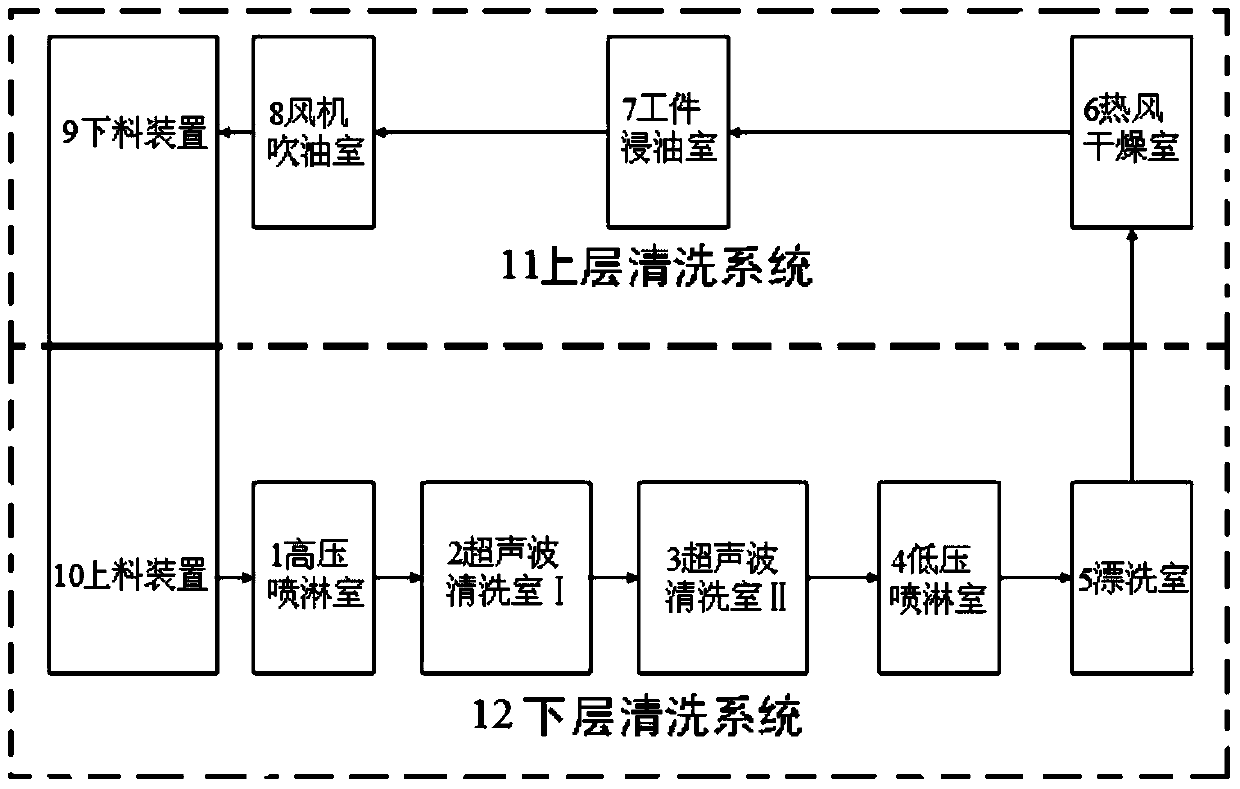

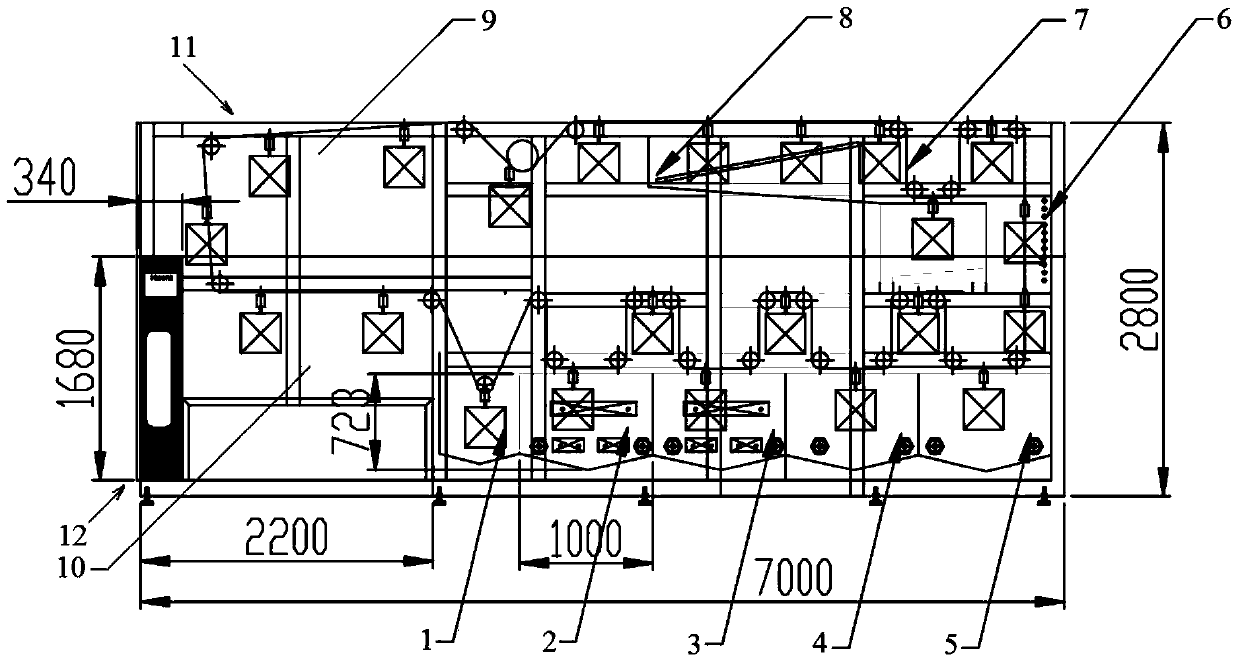

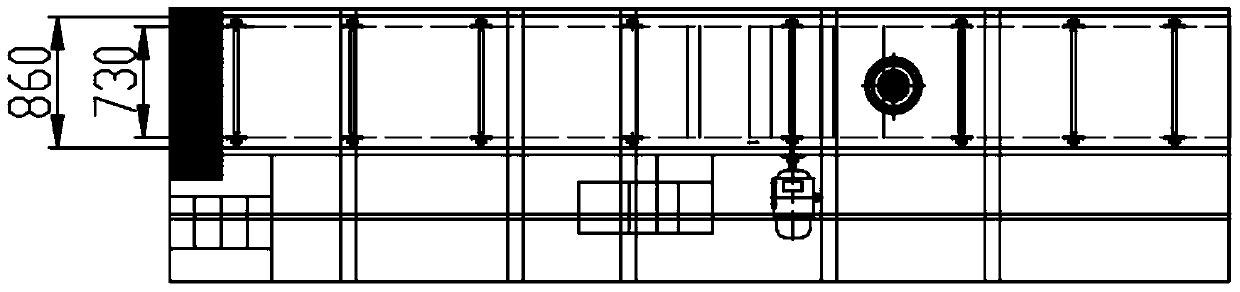

[0030] Such as figure 1 As shown, the process flow of the double-layer turbocharger housing parts automatic ultrasonic integrated cleaning machine of the present invention is as follows:

[0031] The cleaning machine is designed with a double-layer reciprocating structure. The lower layer has the following steps: feeding → high-pressure spraying (pressure 0.4MPa) → ultrasonic cleaning Ⅰ → ultrasonic cleaning Ⅱ → low-pressure spraying (pressure 0.1MPa) → rinsing, the upper layer The process is as follows: hot air drying → oil immersion of the workpiece → oil blowing by fan → unloading, the unloading outlet and the loading inlet are the same inlet and outlet. The parts enter the cleaning machine from the feeding inlet of the lower layer through the conveying system. After the process of the lower layer is completed, the fixture frame with the parts is transported to the upper layer of the washing machine by the guide rail, and the hot air drying process starts. Take out the par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com