Adjustment method of plug replacement process for conical piercer

An adjustment method and piercing machine technology, applied in the direction of manufacturing tools, metal processing equipment, metal rolling, etc., can solve the problems of increasing difficulty in planning and scheduling, and reduce the occurrence probability, the frequency of replacement, and the reduction of folding and crack defects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

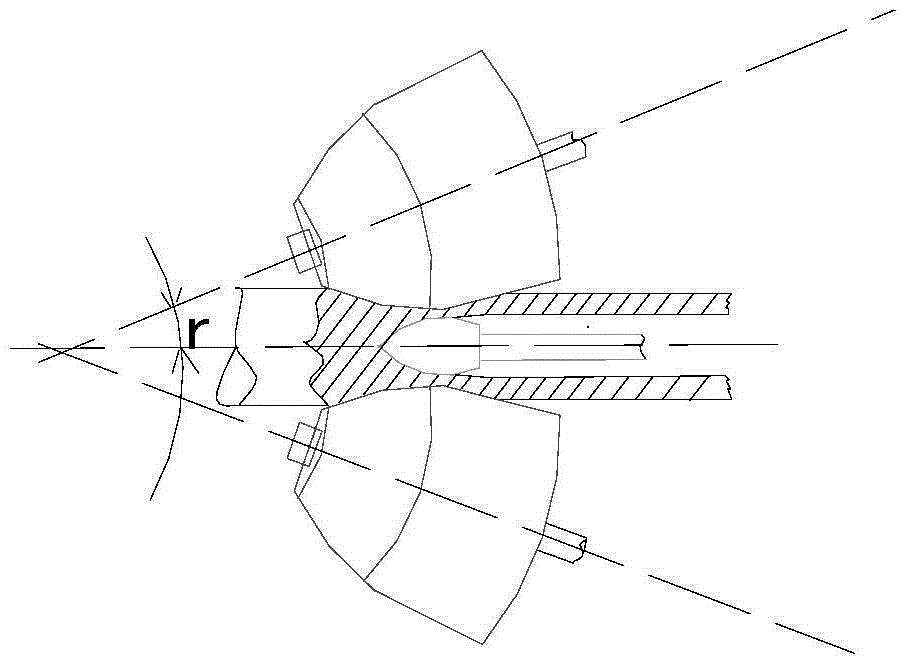

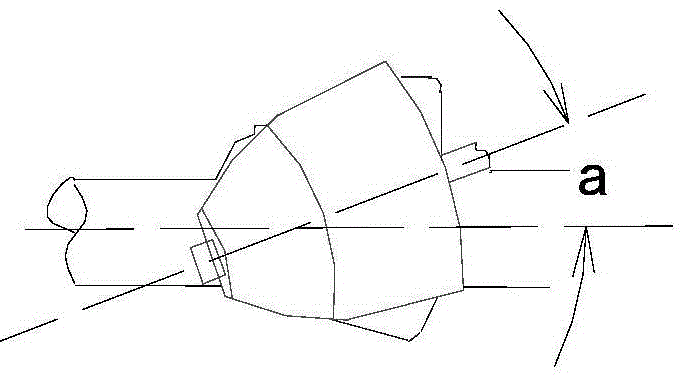

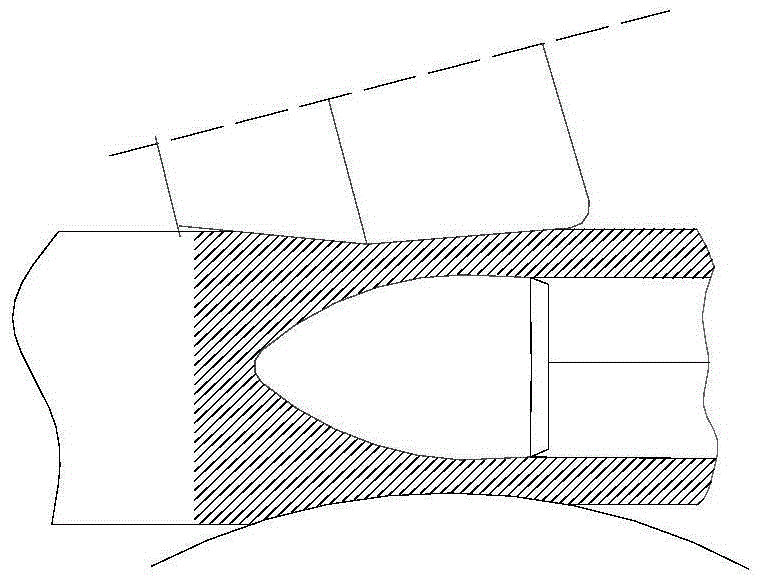

[0019] The adjustment method of the taper piercer plug replacement process of the present invention will be described in conjunction with the accompanying drawings.

[0020] The design concept of the adjustment method of the plug replacement process of the conical piercer of the present invention is to apply plugs of adjacent specifications to replace rolling on the basis of the original plug specifications based on the rolling count of the piercing rolls and the corresponding wear degree, and according to Based on the deformation principle of the piercing machine, the corresponding process adjustment method has been established. According to the above-mentioned problems, according to the change of the wear amount of the perforated roll summarized, and through the comparison of the lathe processing data, it can be known that when the rolling count of the perforated roll reaches 8,000, the wear amount of the roll is 4-5mm; when the rolling count reaches 20,000 , The amount of r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com