Rolling-contact shaft member

A rolling contact, shaft component technology, applied in the direction of anti-centrifugal force rotating parts, bearing components, engine components, etc., can solve the problems of many heat treatment processes, long shaft manufacturing time, and high manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

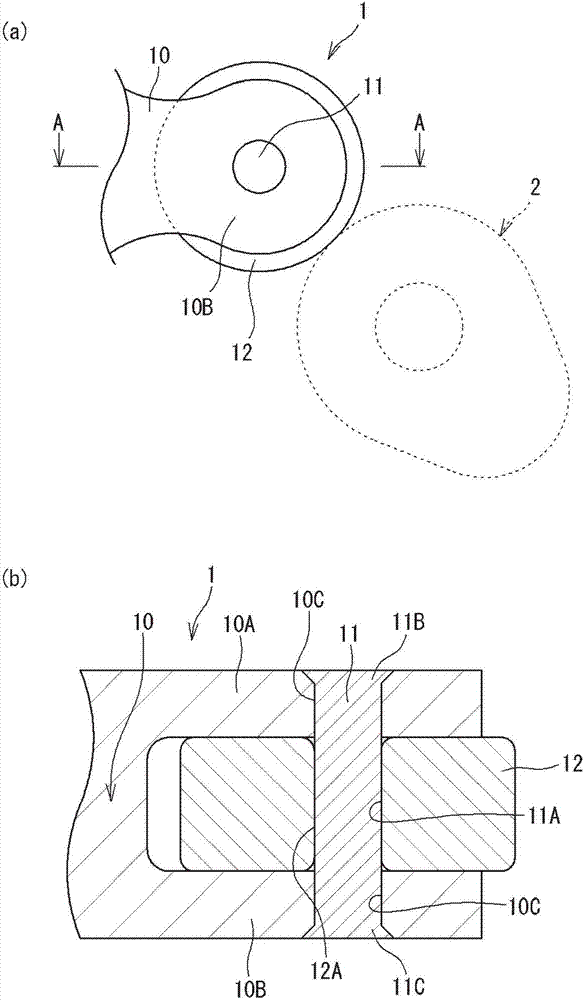

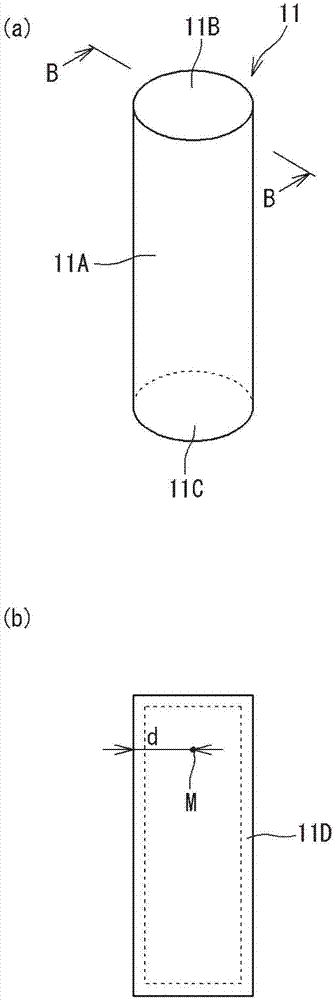

[0020] Hereinafter, a shaft member for rolling contact according to an embodiment of the present invention will be described with reference to the drawings. The rolling contact shaft member according to the embodiment of the present invention can be used as a shaft for rotatably supporting a rocker roller included in a rocker arm (rocker roller shaft). figure 1 (a) is a front view showing a part of the roller rocker using the rolling contact shaft member according to the embodiment of the present invention. figure 1 (b) is figure 1 (a) A-A line sectional view. figure 2 (a) is figure 1 A perspective view of the shaft member for rolling contact shown. figure 2 (b) is figure 2 (a) B-B line sectional view.

[0021] Such as figure 1 As shown in (a) and (b), the roller rocker arm 1 includes a rocker arm main body 10 , a rocker roller shaft (hereinafter also simply referred to as a shaft) 11 , and a rocker roller 12 in contact with the cam 2 . The rocker arm body 10 include...

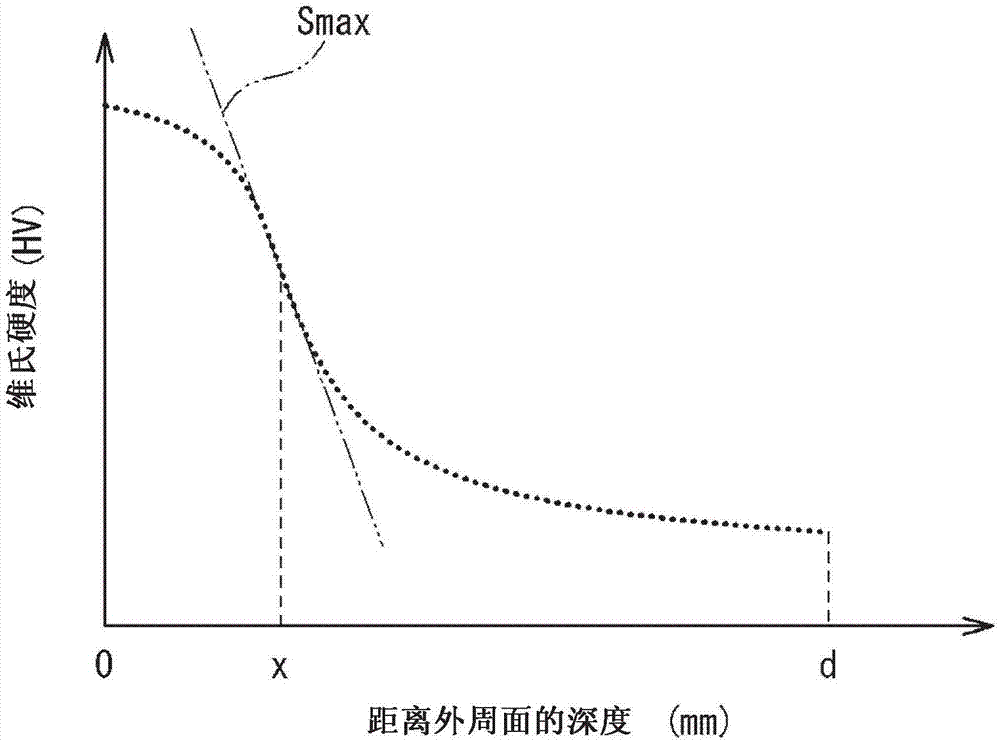

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com