Bearing device for wheel

一种轴承装置、车轮的技术,应用在轴承、车轴、车轮等方向,能够解决减少纤维流线截断的措施、是否能够适用或应用不清楚、相对纤维流线角度未被考虑等问题,达到滚动寿命提高、切削加工时间缩短、加工余量削减的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

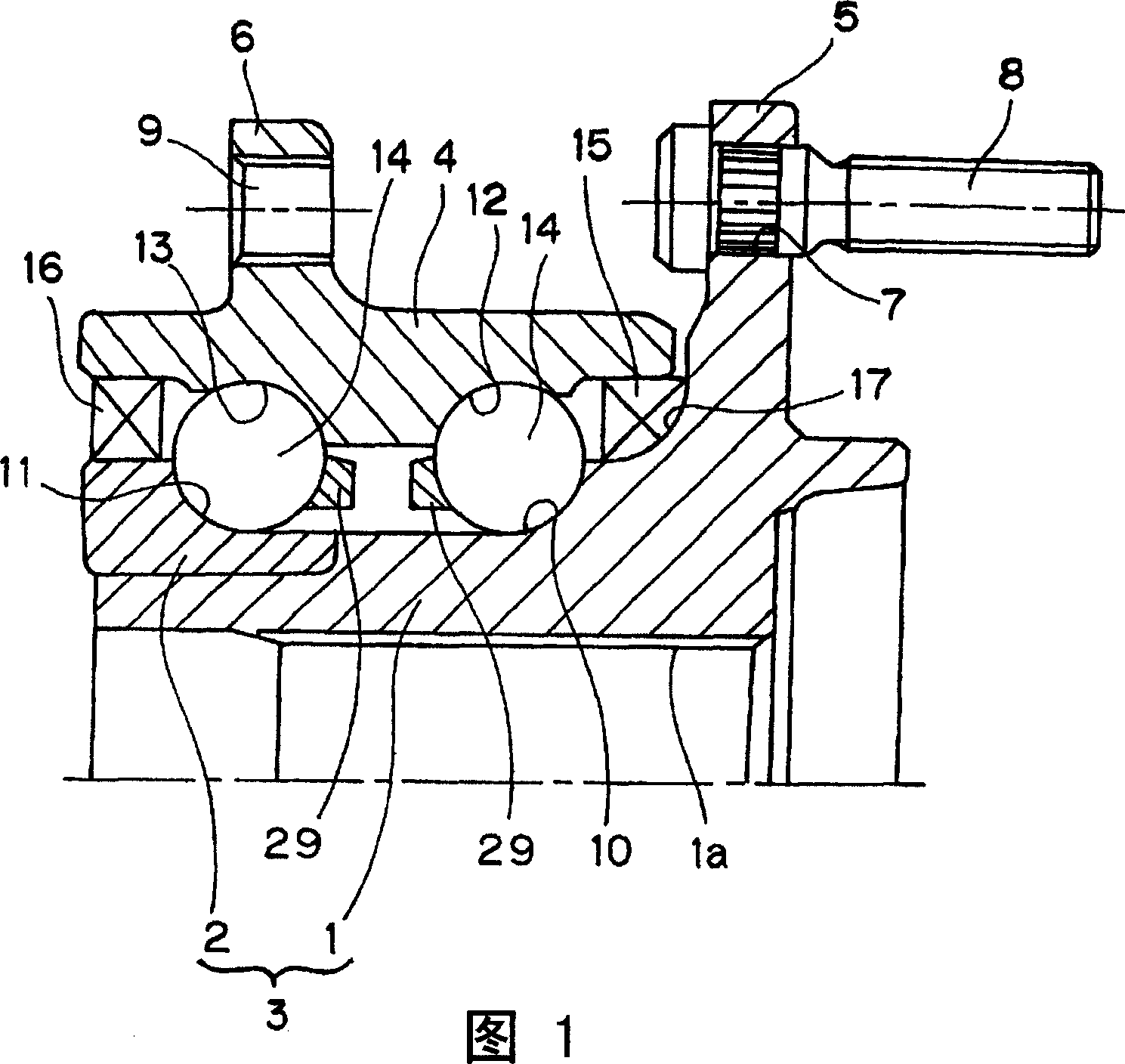

[0038] The first embodiment of the present invention will be described below based on Fig. 1 to Fig. 7 . This embodiment is an example of a third-generation spherical type, drive wheel, and inner ring rotation type wheel bearing device. The wheel bearing device includes an inner part 3 and an outer part 4. The inner part 3 is composed of a hub ring 1 and an inner ring 2 fitted with the outer circumference of the inner end of the wheel hub ring 1. The wheel bearing device is rotatable. The way to support the wheels on the vehicle body. The outer end of the hub 1 has a flange 5 for mounting a wheel, and bolts 8 for mounting a wheel are press-fitted into bolt insertion holes 7 formed at a plurality of positions in the circumferential direction of the flange 5 . In addition, this hub wheel 1 constitutes a cylindrical member through which an intermediate hole 1 a penetrates. A shaft portion of an outer joint member of a constant velocity universal joint not shown in the figure is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com