Flap wheel mounting and clamping mechanism

A technology of wheel clamping and thousand-page wheel, which is applied in the field of thousand-page wheel clamping mechanism, can solve problems such as troublesome installation and processing, is not conducive to the rapid replacement of thousand-page wheels, and cannot realize system overload protection, etc., and achieves convenient disassembly and installation. And dismantling is easy and feasible, and the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

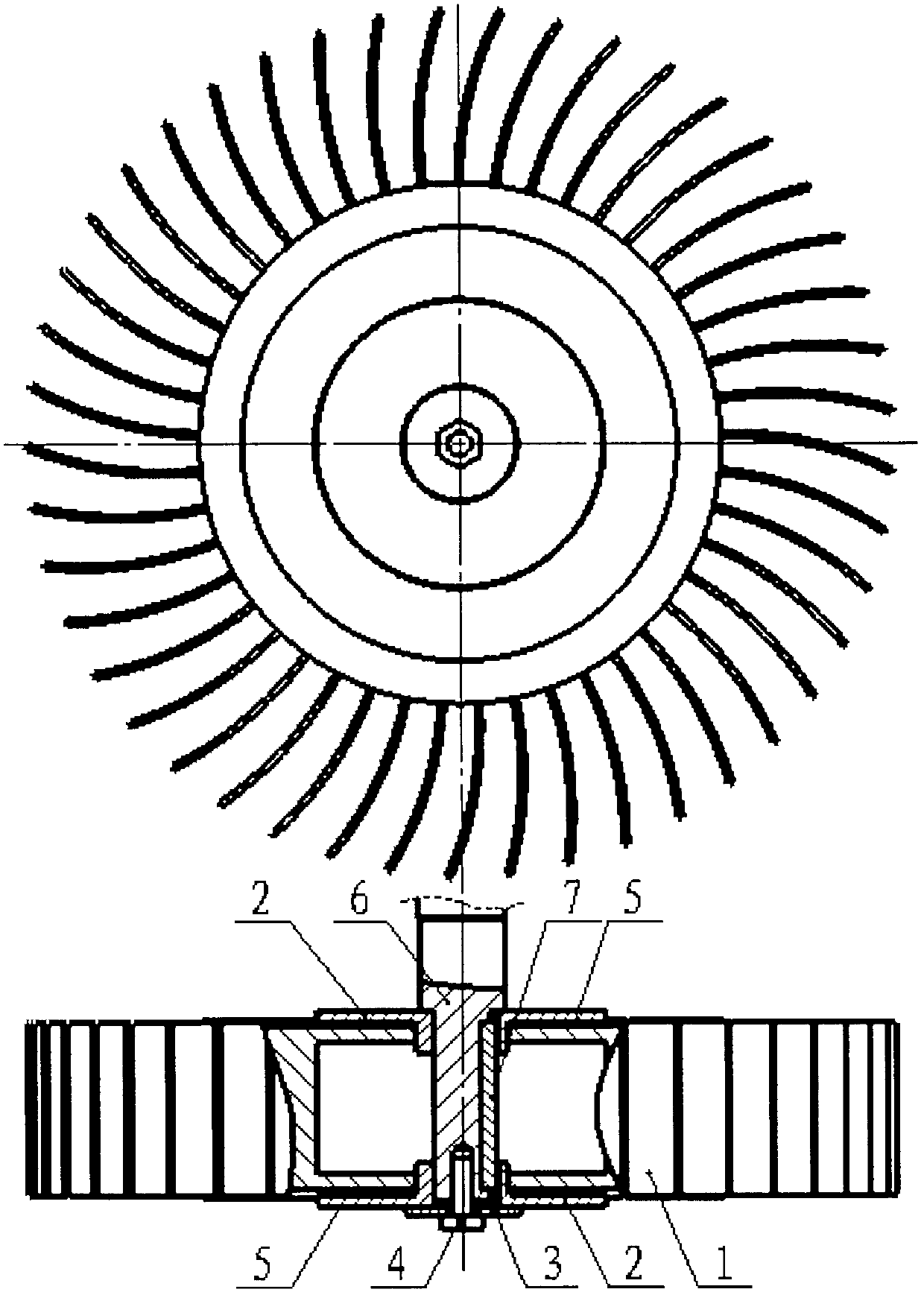

[0022] A clamping mechanism for a thousand-leaf wheel includes a connecting flange 2, a key 7, a pressure plate 3, a compression screw 4 and a rubber pad 5; the drive shaft belt drives the flange to rotate through the key, and the flange drives the thousand-leaf wheel to rotate through friction.

[0023] There are two connecting flanges 2, and the center of the flange has a boss on one side. The shaft head and the key 7 assembly of flange endoporus and power transmission shaft 6, the bosses of two flanges are installed face to face. The flange boss is assembled with the thousand-leaf wheel 1 mounting hole, the thousand-leaf wheel is installed between the two flanges, and a rubber pad is installed between the inner surface of the flange and the thousand-leaf wheel side mounting surface. A threaded hole is processed in the center of the outer side of the shaft head of the transmission shaft, a pressing plate 3 is installed on the outer side of the outer flange, and the compressi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com