Method for forming pattern material layer on non-paper base material and related product

A material layer and pattern technology, applied in the field of multi-functional loose-leaf books, can solve the problems of inconvenient collection, display, use, and inability to act

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

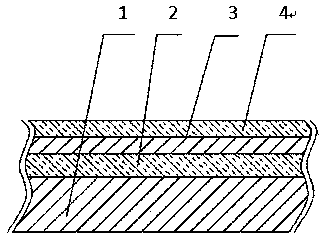

[0030] The situation of coating irreversible thermochromic dyes on one side of the non-paper substrate to form a pattern material layer as described in the present invention is as follows: figure 1 Shown:

[0031] Take mobile phone case, mobile phone back cover, tablet computer case, mobile phone protective case, and tablet computer protective case products as examples, such as figure 1 As shown, the heat insulation layer 2 is coated on the surface of the product base material 1, and there is a pattern material layer 3 formed by an irreversible thermochromic dye outside the heat insulation layer. Between the heat insulation layer and the product surface, the heat insulation layer and the pattern material There may be an intermediate layer with other functions between the layers, and there may be a functional protective layer 4 outside the pattern material layer, and the product can form a predetermined pattern on the surface after undergoing heat or photothermal radiation proc...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap