Station ascending/descending arm

A work station and upper arm technology, applied in cranes, transportation and packaging, etc., can solve the problems of reduced production efficiency, consumption of manpower and material resources, and inability to realize the left and right movement of pipe fittings, so as to save manpower and material resources and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

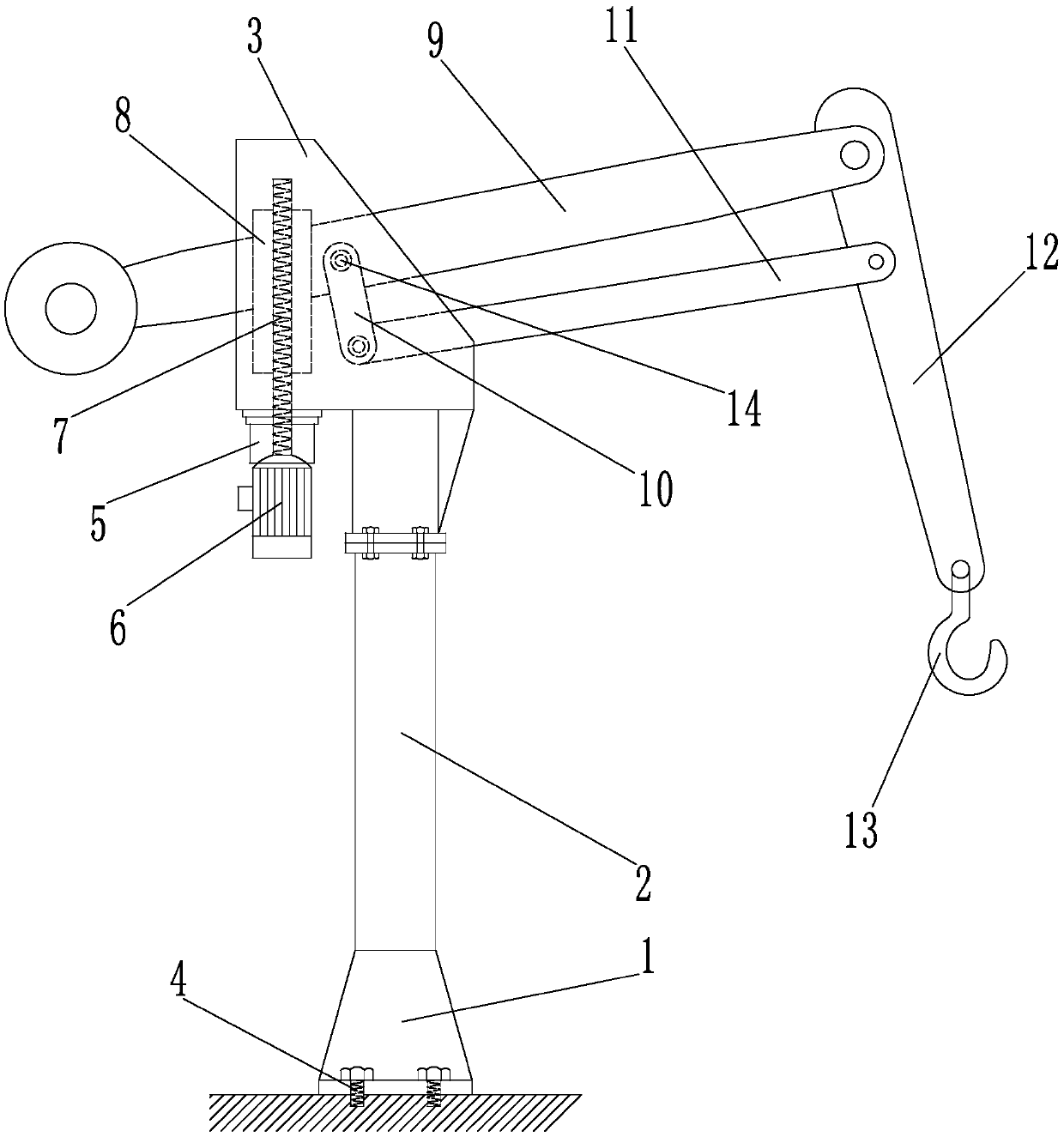

[0009] like figure 1 As shown, the present invention comprises base 1, support column 2 and trapezoidal work box 3, and described base 1 is fixed on the ground by the bolt 4 of its bottom end, is welded with support column 2 at the top of base 1, and described trapezoidal work box 3 Be welded on the top of support column 2, be provided with motor mount 5 at the left lower end of trapezoidal work box 3, motor 6 is installed in described motor mount 5, lead screw 7 is installed at the top of motor 6, described lead screw 7 is equipped with a long nut 8, the long nut 8 is welded with a lift arm 9, and the lift arm 9 is connected to the lift lower arm 11 through the middle plate 10 at the position close to the long nut 8, and the lift arm 9 and the A swing arm 12 is provided at the front end of the lifting lower arm 11 , and a hook 13 is installed at the bottom end of the swing arm 12 .

[0010] The parts of the middle plate 10 located at the upper lifting arm 9 and the lower lif...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap