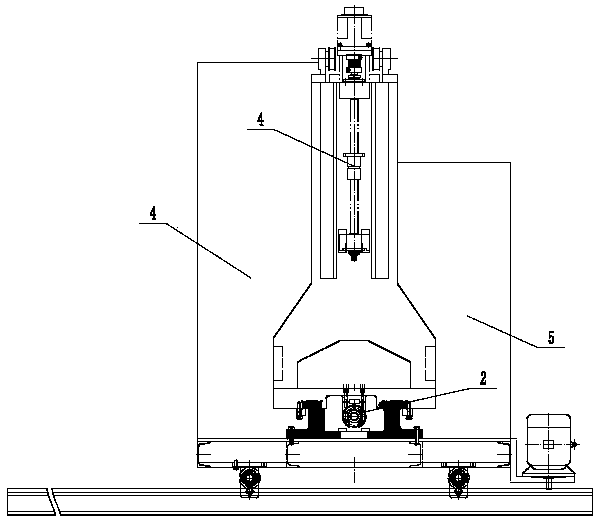

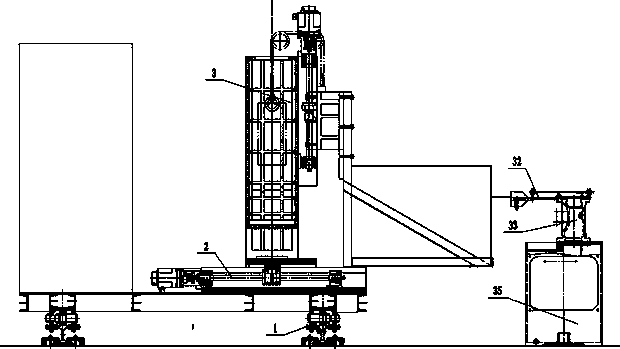

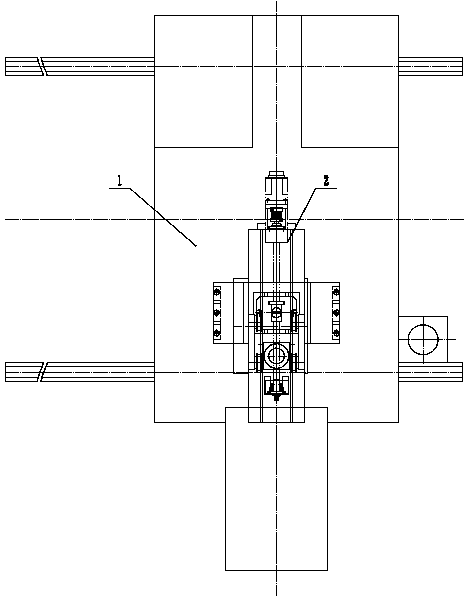

Self-propelled bed body quenching equipment

A quenching equipment and self-propelled technology, applied in the field of CNC machine tools, can solve the problems of single processing object, poor precision and high cost, and achieve the effect of ensuring precision and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Clamp the workpiece 33 on the fixture 35, run the Y-direction motor 18 and the Z-direction motor 29, so that the quenching inductor 32 conforming to the shape of the workpiece 33 is close to the workpiece 33, run the deceleration motor, and use the marking on the transformer cabinet 24 to target the workpiece 33 Alignment, after the end of alignment, run Y direction motor 18 and Z direction motor 29 again, so that the quenching inductor 32 and workpiece 33 reach the quenching distance.

[0024] When running the Z-direction motor 29, the motor drives the Z-direction screw 34 to drive the Z-direction sliding seat 22 to move up or down. At this time, the counterweight 27 balances the weight of the Z-direction sliding seat 22 and the transformer seat 23 through the sprocket wheel 26 to improve the accuracy. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com