High-strength and high-toughness hot-rolled magnet yoke steel with yield strength greater than or equal to 650 MPa and production method

A yield strength and high-strength technology, which is applied in the field of high-strength and high-toughness hot-rolled yoke steel with yield strength ≥ 650MPa and the production field to achieve a good matching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention is described in detail below:

[0031] Table 1 is the value list of the chemical composition of steel of the present invention and comparative example;

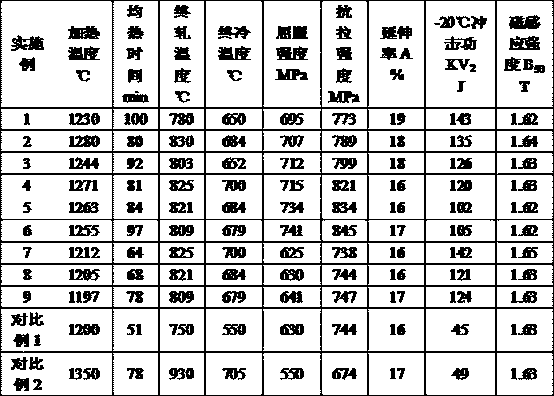

[0032] Table 2 is a list of main process parameter values and performance testing of the steel of the present invention and comparative examples.

[0033] Each implementation of the present invention is produced according to the following steps:

[0034] 1) Casting into slabs after molten iron desulfurization, converter top-bottom composite blowing, and vacuum treatment;

[0035] 2) Heating the slab, the heating temperature is 1230-1280°C, and the soaking time is 80-100min;

[0036] 3) Carry out rough rolling, and control the end temperature of rough rolling not lower than 1050°C;

[0037] 4) Carry out finish rolling, and control the finish rolling temperature at 800-850°C;

[0038] 5) Carry out laminar flow cooling, and the final cooling temperature is 600-650°C;

[0039] 6) Carry out coil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com