A light steel keel foundation structure system and construction method for a light partition wall

A light steel keel and foundation structure technology, which is applied in the direction of walls, building components, building structures, etc., can solve the problems of inaccurate lap joint position, poor finish surface flatness, uneven keel surface, etc., and achieve fast construction and installation. The installation surface is flat and the construction precision is high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to illustrate the technical solutions of the present invention more clearly, the technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments. Obviously, the following descriptions are only some embodiments of the present invention, which will be useful to those skilled in the art. In other words, other embodiments can also be obtained based on these embodiments without creative effort.

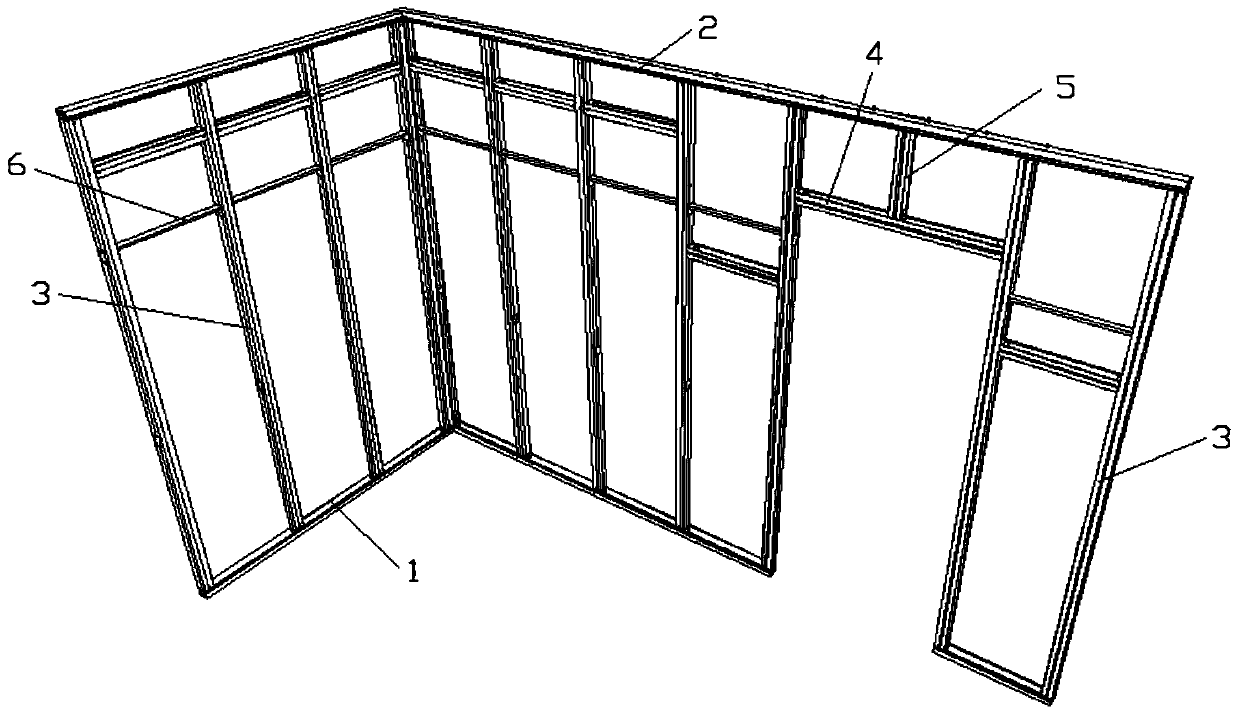

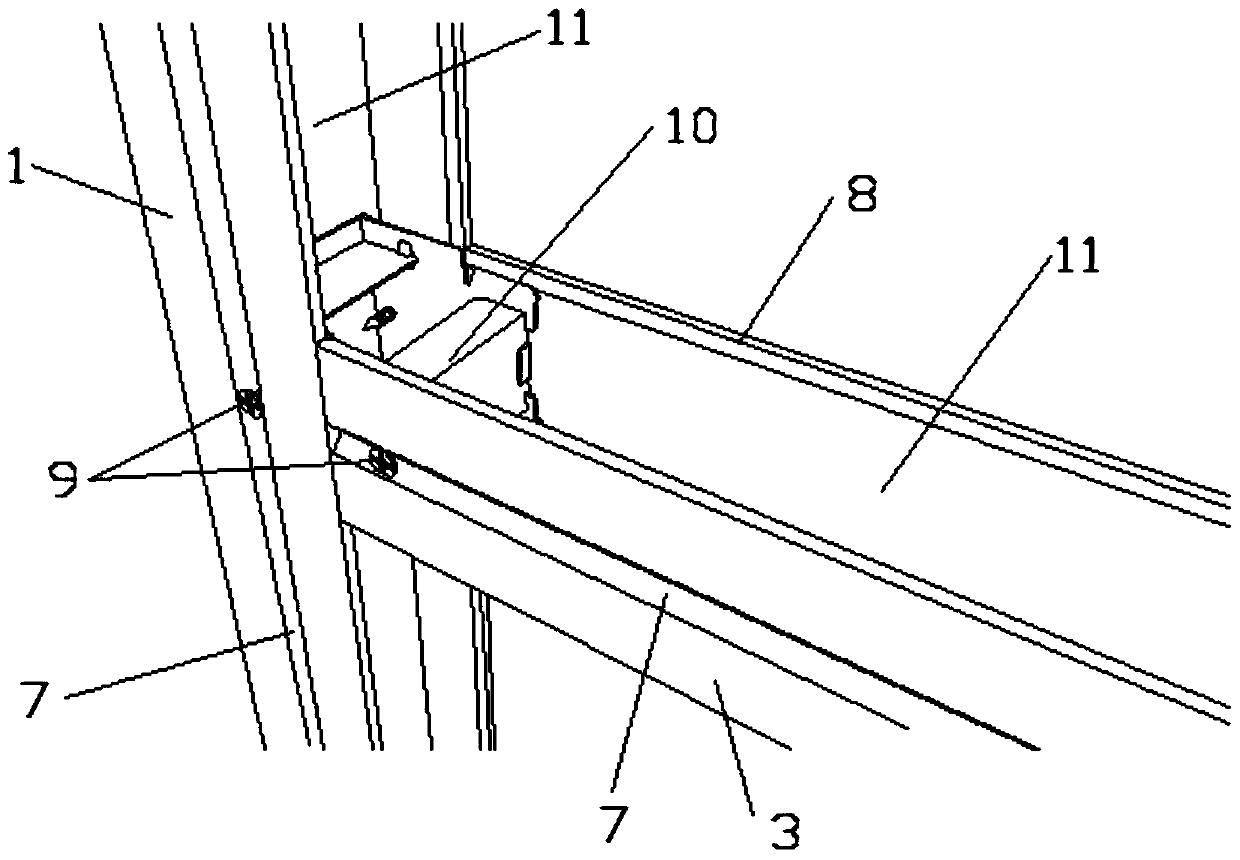

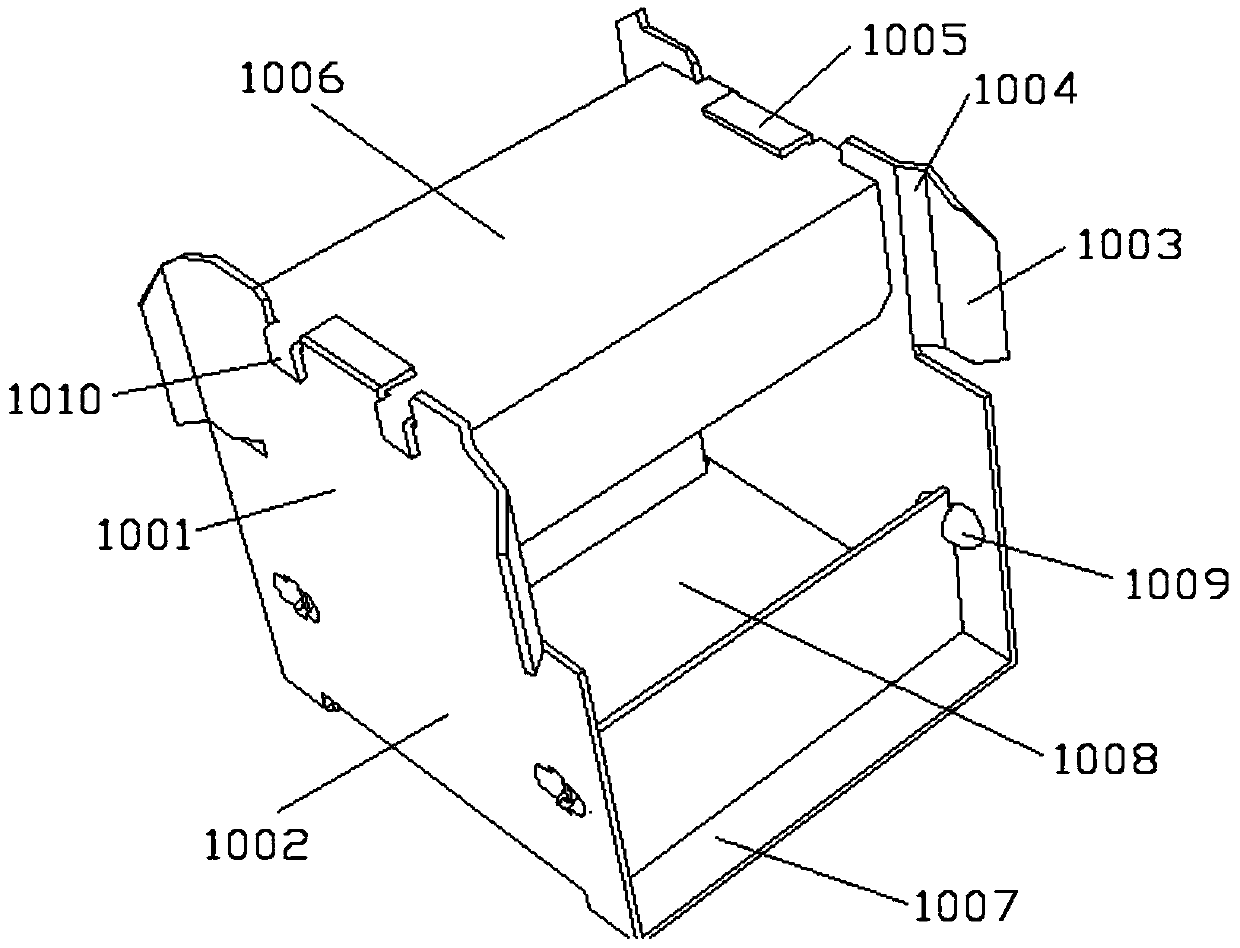

[0031] refer to Figure 1 to Figure 8 , a light steel keel basic structure system for lightweight partition walls, used for lightweight partition wall systems, especially suitable for various wall panels with a thickness between 10mm and 30mm; the light steel keel of the lightweight partition wall The basic structure system includes heaven and earth keel and vertical keel 3 vertical keel 4 vertical keel 5, heaven and earth keel and vertical keel 3 vertical keel 4 vertical keel 5 are U-shaped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com