Mould for manufacturing craft cement flower box

A technology for making crafts and molds, which is applied in the field of molds for making craft cement flower boxes, which can solve problems such as short service life of molds, easy corrosion of wooden flower boxes, poor water and fertilizer retention, and achieve beautiful appearance, corrosion resistance and longevity The effect of improving and making mold convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

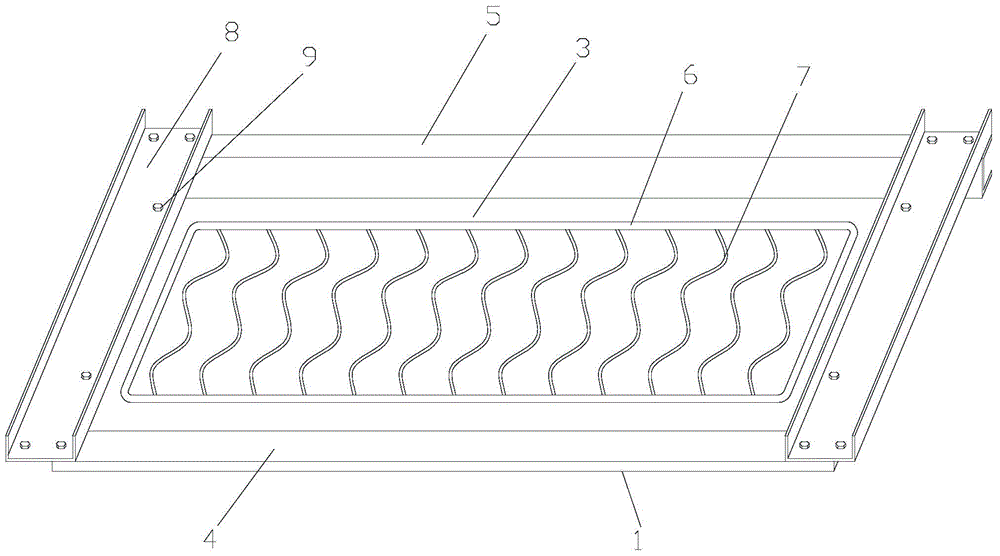

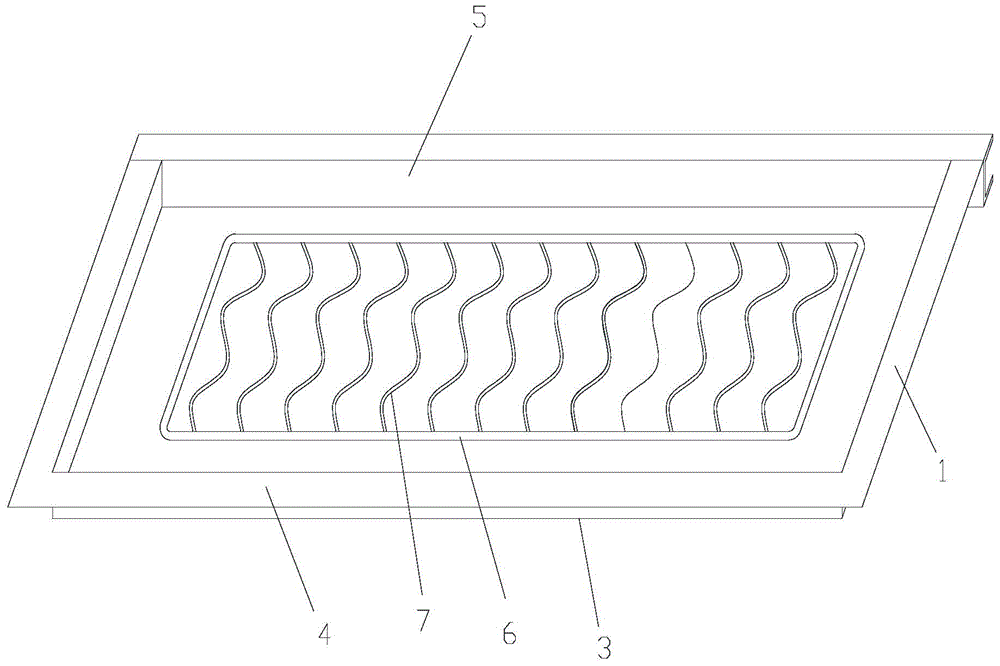

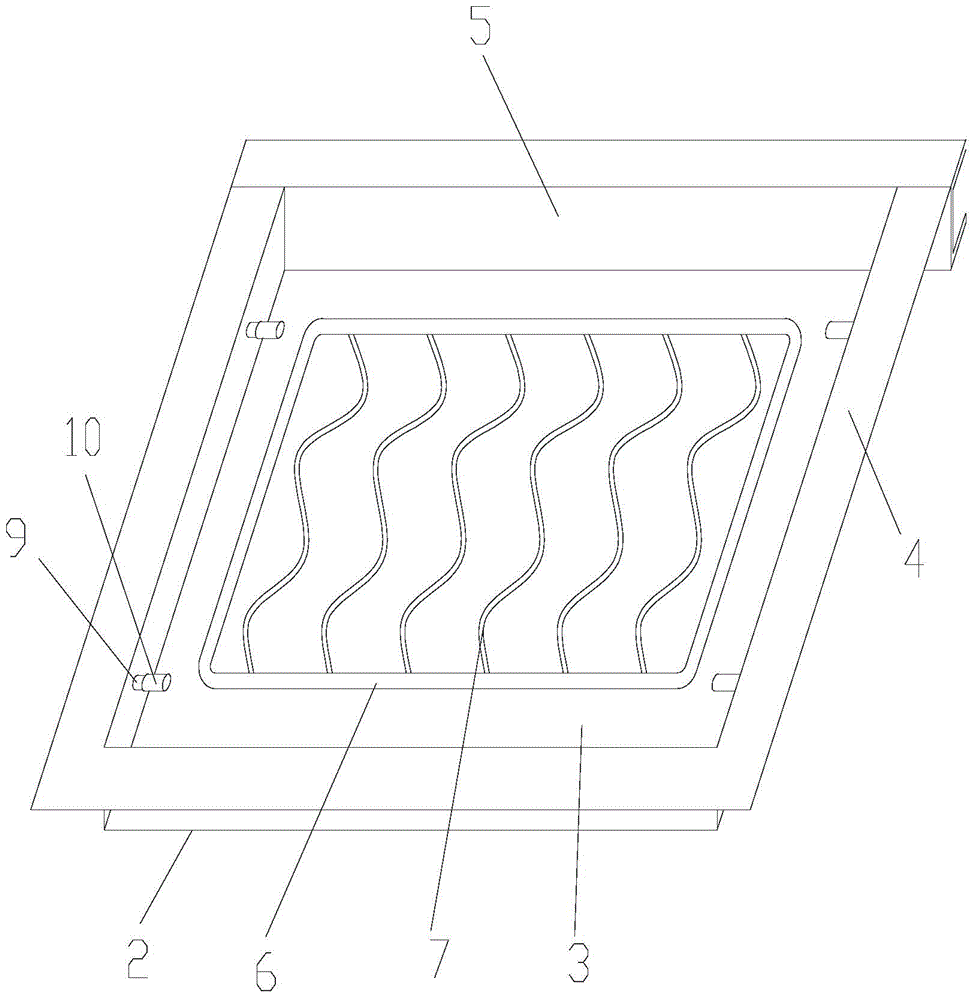

[0017] Attached below Figure 1-4 An embodiment of the present invention is described.

[0018] A mold for making a craft cement flower box includes a mold body I1 and a mold body II2, and the mold body I1 and mold body II2 are both composed of a C-shaped groove 3 with a bottom surface, an edge plate 4 and a mold sealing plate 5. The edge plate 4 is arranged on the edge of the upper end of the C-shaped groove 3, and the mold-lifting sealing plate 5 is fixed on the outer side wall of the opening end of the C-shaped groove 3, and a square ring groove 6 is formed on the inner bottom surface of the C-shaped groove 3. and patterns 7, screeds 8 are fixed on both sides of the upper end surface of the mold body I1, and the inner side of the screed plate 8 and the two side walls of the mold body II2 are equipped with workpiece reserved hole devices and correspondingly arranged; , the workpiece reserved hole device includes a bolt 9 and a screw sleeve 10, the upper end of the bolt 9 on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com