Sealed bus connecting sleeve for gas-insulated switchgear

A busbar connection with sealing technology, which is applied in busbar/circuit layout, electrical components, switchgear, etc., can solve the problems of low mechanical strength, low safety, poor sealing, etc., and achieve high mechanical strength, high processing precision, and lowered effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

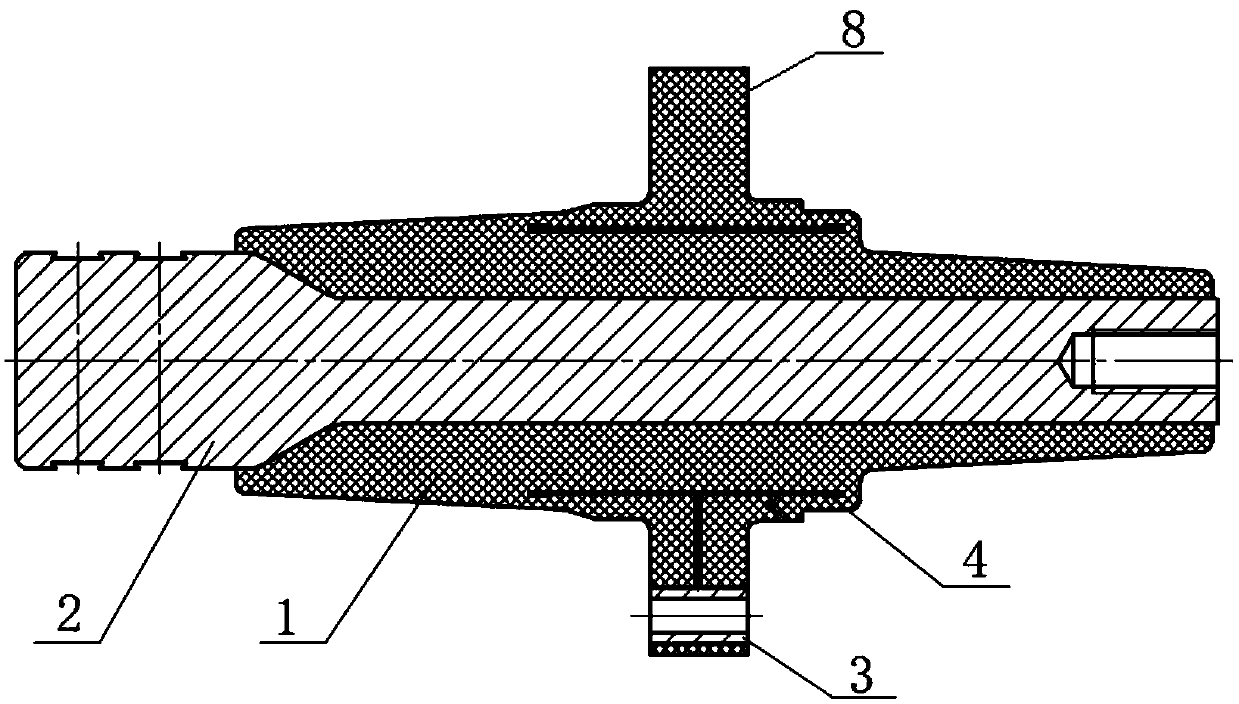

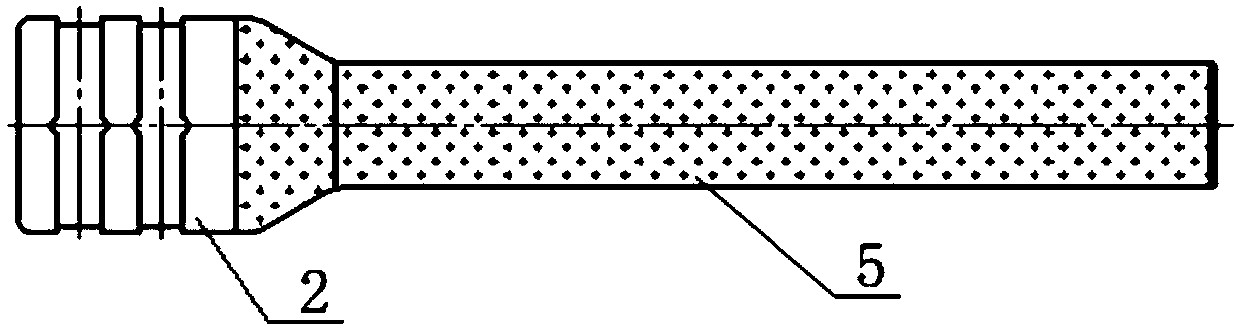

[0019] Such as figure 1 As shown, the present invention provides a sealed bus connection bushing for an inflatable cabinet, including a conductive rod 2 and an insulator 1 wrapped on the outside of the conductive rod 2, wherein the outer surface of the insulator 1 is provided with a flange 8 along the circumferential direction, and the flange 8 An installation insert 3 is provided on the top, and a shielding net 4 is provided at a position opposite to the flange 8 in the insulator 1 , and the shielding net 4 is connected to the installation insert 3 .

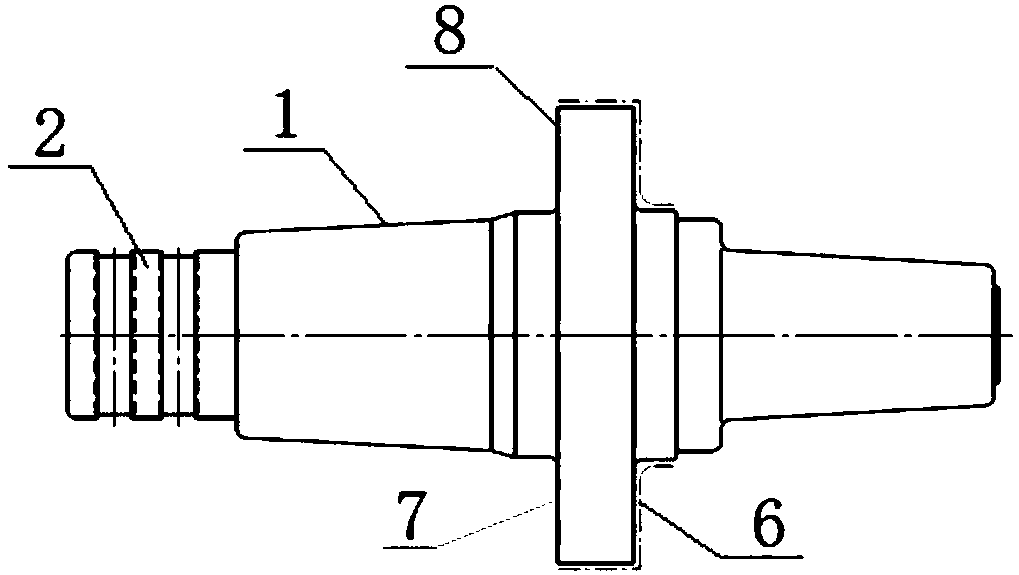

[0020] Such as image 3 As shown, the insulator 1 adopts an epoxy resin cast integral structure, and the outer surface is sprayed with an aluminum layer 6 , and the aluminum layer 6 is connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com