tongue-and-groove connection structure of building formwork

A technology for building templates and connecting structures, which is applied to the connection parts of formwork/formwork/work frame, building structure, formwork/formwork components, etc., which can solve the problems of high connection strength and fast connection speed, and ensure the connection Strength, the effect of achieving connection strength and preventing separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

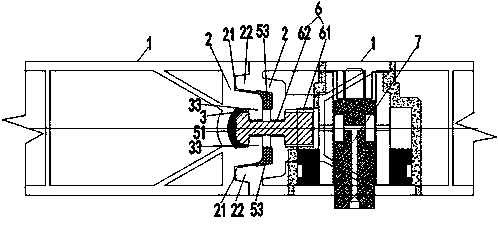

[0046] Such as figure 1 and 2 As shown, the tongue-and-groove connection structure of the building formwork described in this embodiment has a pouring surface and an outer surface opposite to the pouring side plate; it is formed on the edge 2 between the pouring surface and the outer measuring surface There is a tongue-and-groove structure; the tongue-and-groove structure includes molding on the edge 2, the notch 31 faces the locking groove 3 parallel to the pouring surface, and a locking device arranged on the edge 2 of the adjacent template 1; the The locking device has a locking piece 4 that is relatively movably connected to the adjacent template 1 and is suitable for being embedded in the locking groove 3. The locking piece 4 cooperates with the locking groove 3 to prevent two adjacent templates 1 from interacting with each other. separate. In this embodiment, the setting of the locking member 4 and the locking groove 3 can not only realize the quick connection between ...

Embodiment 2

[0062] As a convertible implementation mode, the difference between this embodiment and embodiment 1 is:

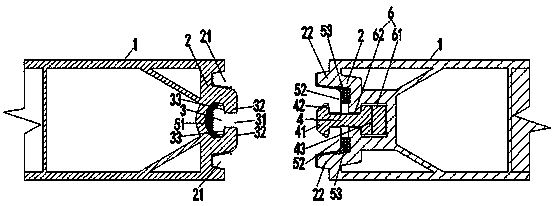

[0063] Such as image 3 As shown, the locking member 4 is rotatably connected to the adjacent template by a pivot set parallel to the direction of the edge 2; the locking member 4 is rotated so that the locking head 41 and the locking surface Lamination. That is, in this embodiment, the locking member 4 can be mounted on the adjacent template 1 on the pivot, and it can rotate around the pivot, so that the locking head 41 is pressed against the locking surface. combined, thereby preventing the separation of two adjacent templates 1

[0064] In this embodiment, the locking members 4 rotate in opposite directions and are arranged in pairs, and the partial pressures in the direction perpendicular to the pouring surface cancel each other when pressed. Specific as image 3 As shown, the locking groove is provided with an intermediate T-shaped portion, the two lateral inner ...

Embodiment 3

[0066] As a convertible implementation mode, the differences between this embodiment and embodiment 1 are:

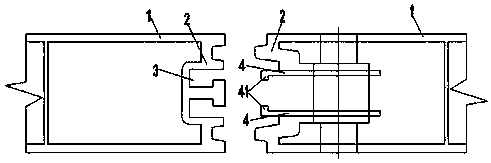

[0067] Such as Figure 4 and Figure 5 As shown, the locking groove 3 is at least one transverse groove arranged alternately along the extending direction of the edge 2; the locking member 4 is a locking hook arranged alternately along the extending direction of the edge 2 and corresponding to the transverse groove; Each of the locking hooks is rotatably connected to the adjacent formwork by a pivot perpendicular to the pouring surface. In the case of more than two locking hooks, a linkage rod keeps each of the locking hooks linked. . In this embodiment, the locking member 4 is set as a locking hook, and when two adjacent templates 1 are connected to each other, the locking hook rotates and engages with the transverse groove, thereby connecting the two templates 1 In the case of a plurality of locking hooks, the same linkage rod is used to drive the locking hooks to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com