Low-rotation-noise cooling fan for automobile engine

A technology of automobile engine and cooling fan, which is applied in the direction of engine cooling, engine components, machine/engine, etc., and can solve problems such as high noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

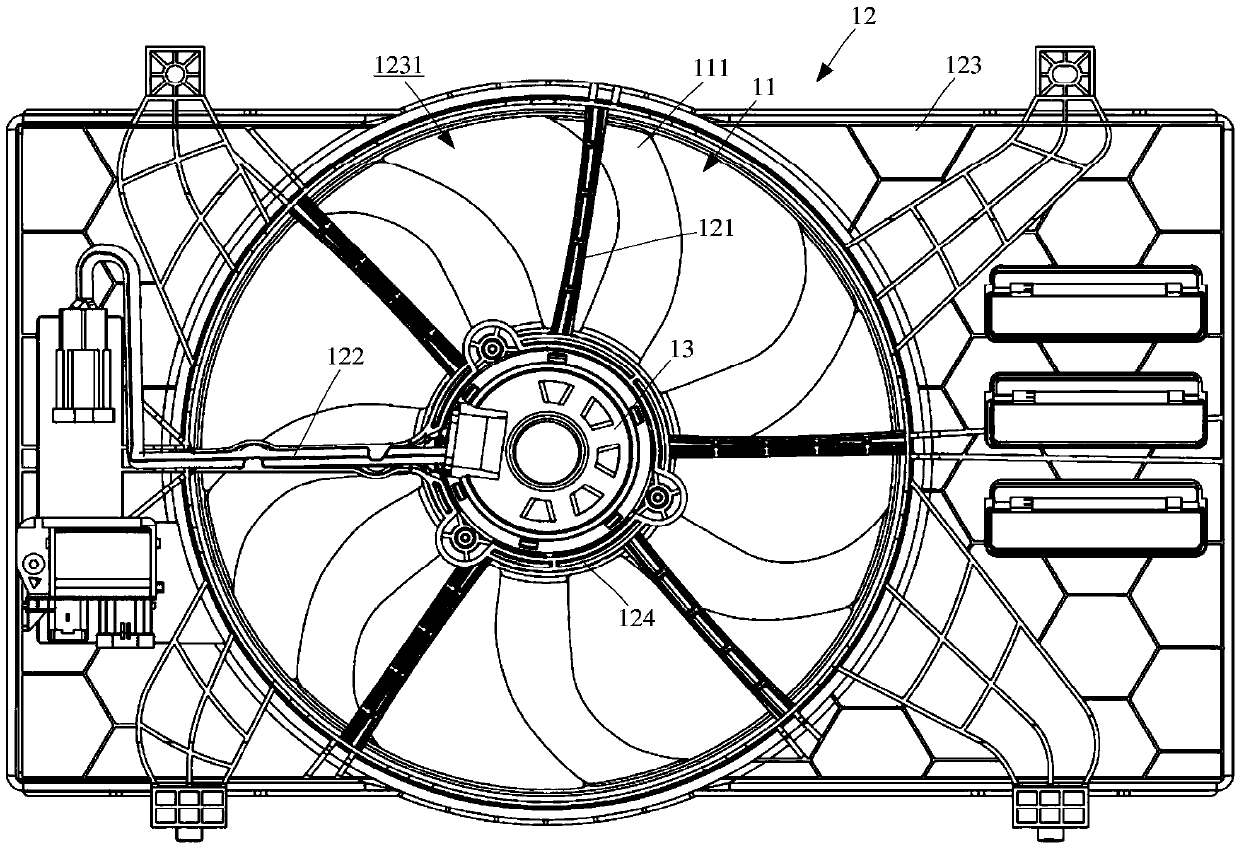

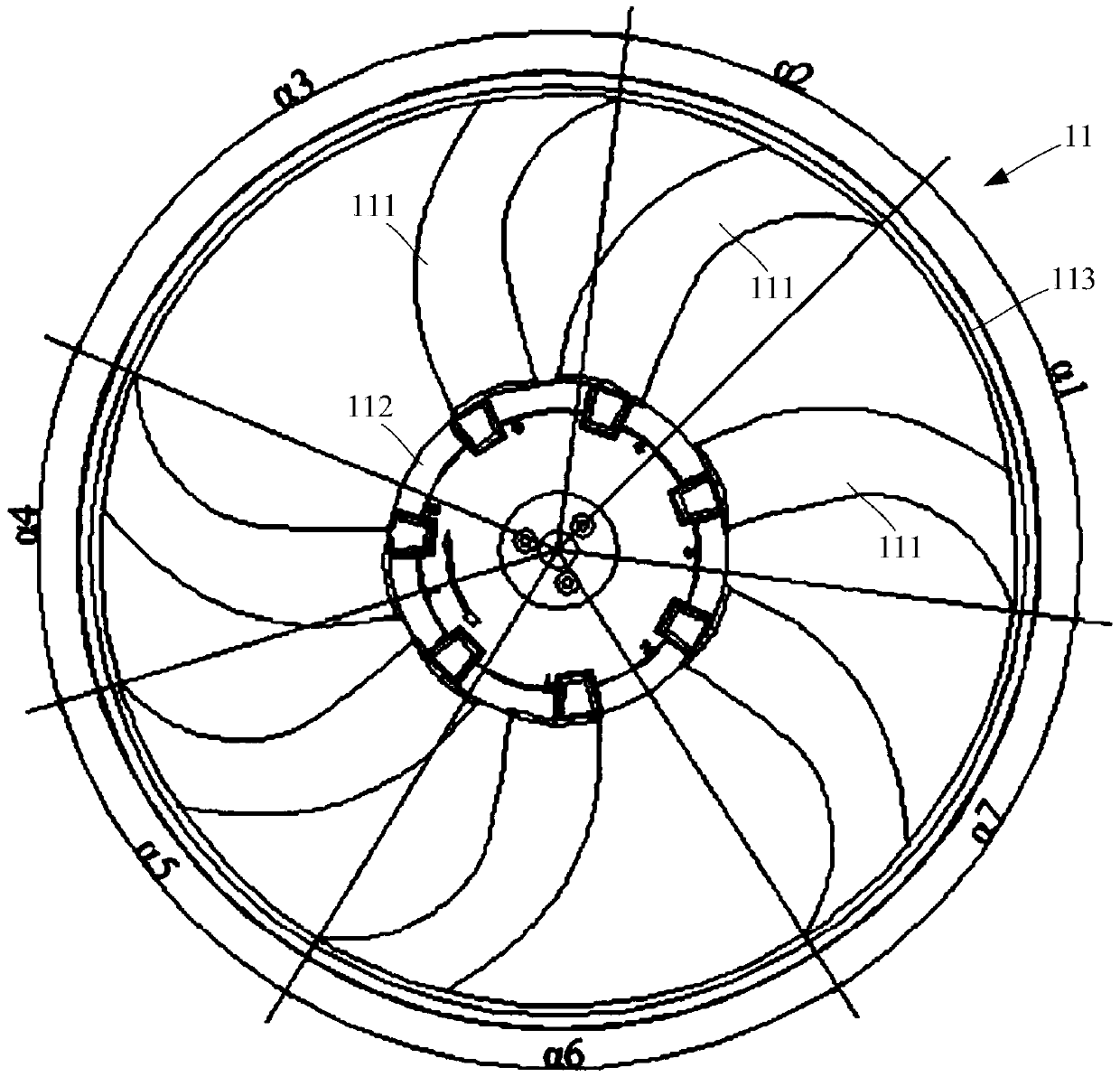

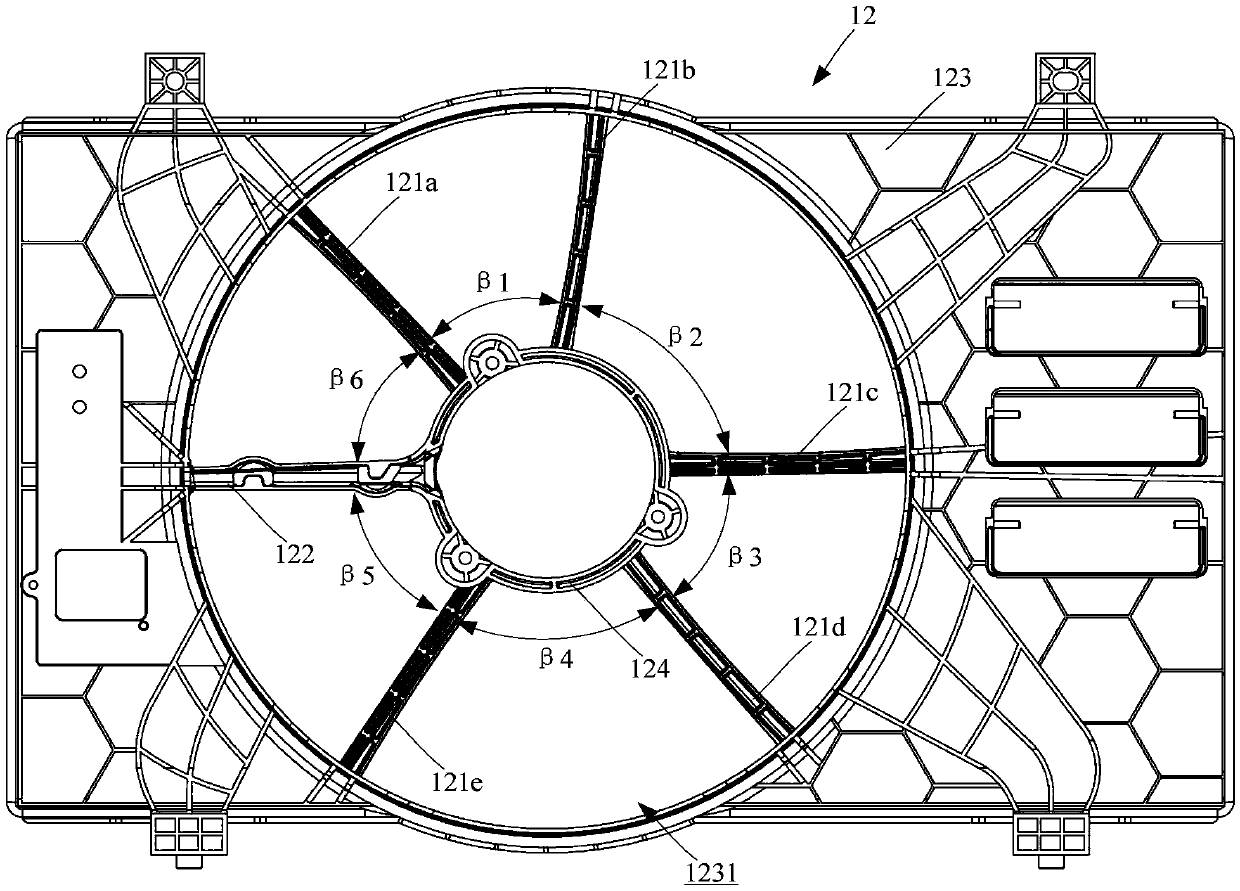

[0030] The invention provides an automobile engine cooling fan with low rotating noise, which is used to solve the problem of relatively large rotating noise caused by uniformly distributed fan blades in the existing cooling fan, and also solves the problem that the fan works due to the setting of supporting ribs More turbulence is generated, which reduces system efficiency and worsens system noise. A low-rotating-noise automobile engine cooling fan of the present invention adopts a fan with non-uniformly distributed fan blades, and sets guide vanes on the windshield ring. The non-uniformly distributed fan blades can ensure that the fan's rotating noise is not in a harmonic order. Superimposition, which effectively reduces the rotation noise of the fan, rectifies the air passing through the fan blade through the guide vane, reduces the rotation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com