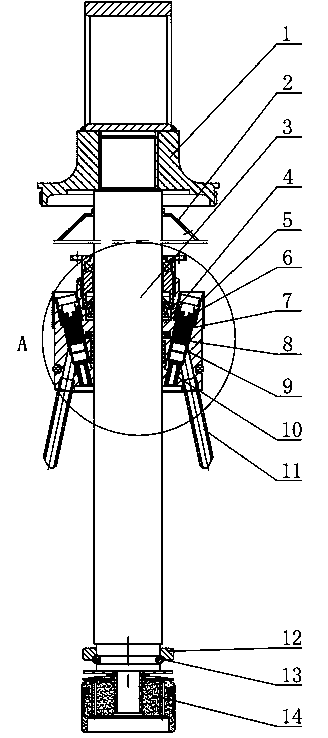

Vertical shock absorber structure with lifting function

A vertical shock absorber and function technology, applied in the direction of shock absorber, spring/shock absorber, shock absorber, etc., can solve the problem that the shock absorber does not have the lifting function, the piston assembly is damaged, etc., and achieves compact structure, Protects the shock absorber and has good reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

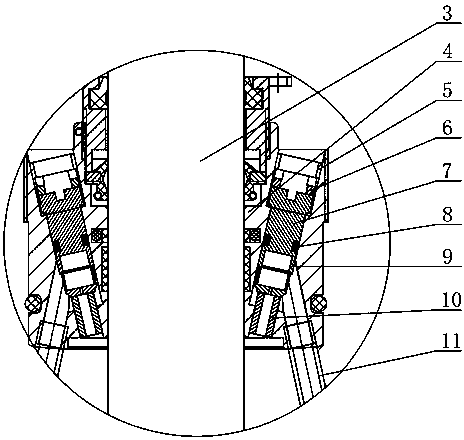

[0014] like figure 1 and figure 2 As shown, the vertical shock absorber structure with a lifting function in this embodiment includes a ring seat assembly 1, a connecting rod 3 is installed on the lower part of the ring seat assembly 1, and a downward telescopic anti-shock is installed on the outer circumference of the connecting rod 3. Dust cover 2, the connecting rod 3 located at the lower end of the telescopic dust cover 2 is equipped with guide seat assemblies of two groups of regulating valves arranged symmetrically, the bottom of the connecting rod 3 is installed with the piston assembly 14, and the connecting rod located at the upper part of the piston assembly 14 3 is provided with a step, and the step is fixed with a stopper 12 through a steel wire retaining ring 13; the structure of the guide seat assembly is: including a guide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com