Control signal dual-switch valve controller convenient to machine and steady in operation

A valve controller and control signal technology, applied in valve details, valve device, valve operation/release device, etc., can solve the problems of unstable structure, complex processing, large space occupied, etc., and achieve simple processing method and structure. , The effect of stable structure and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

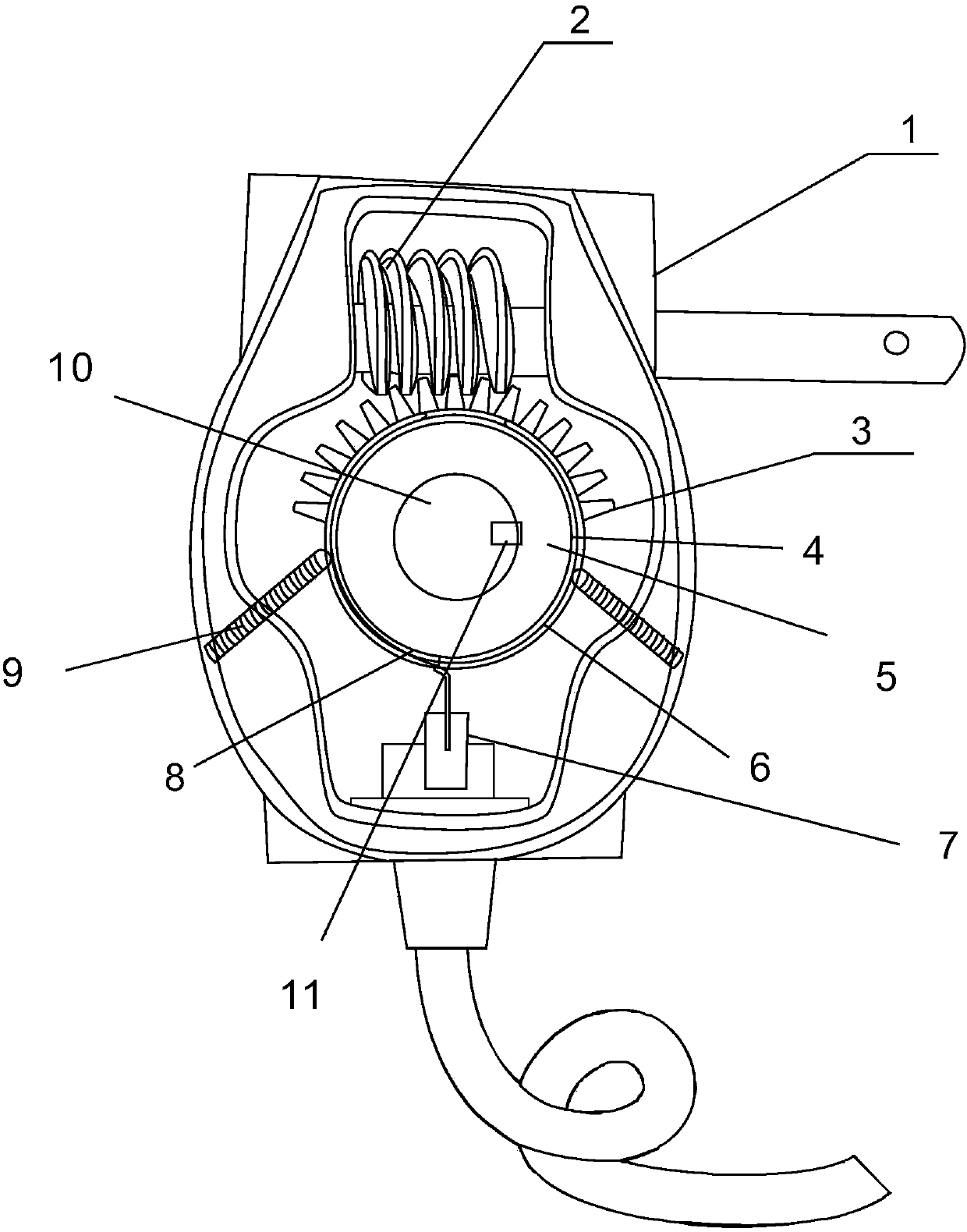

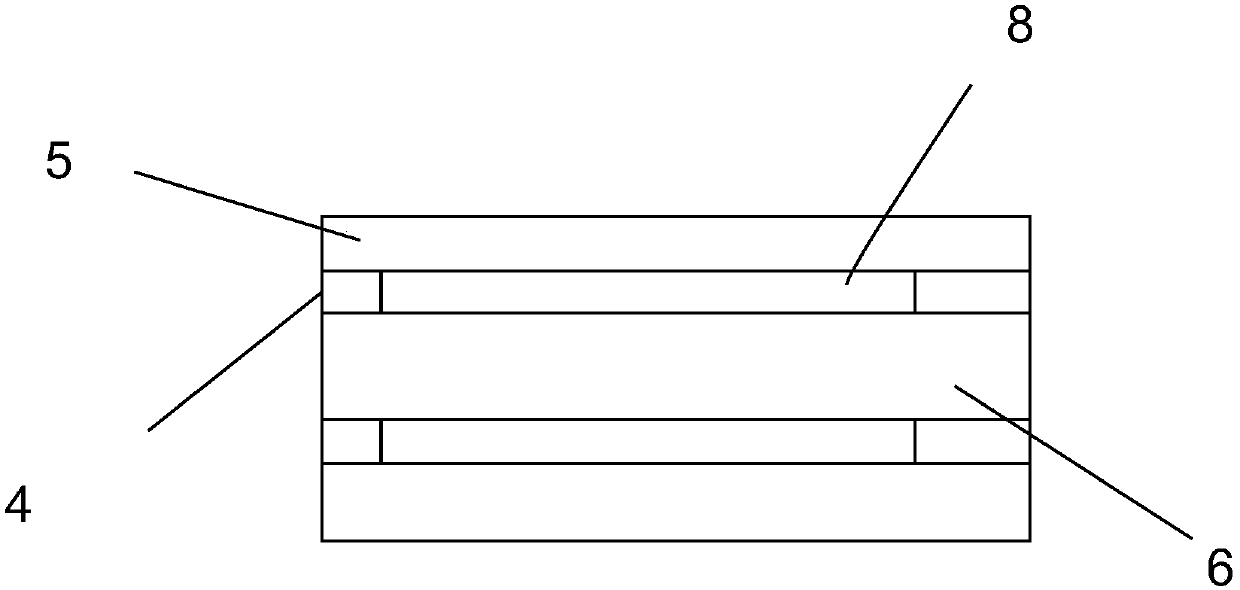

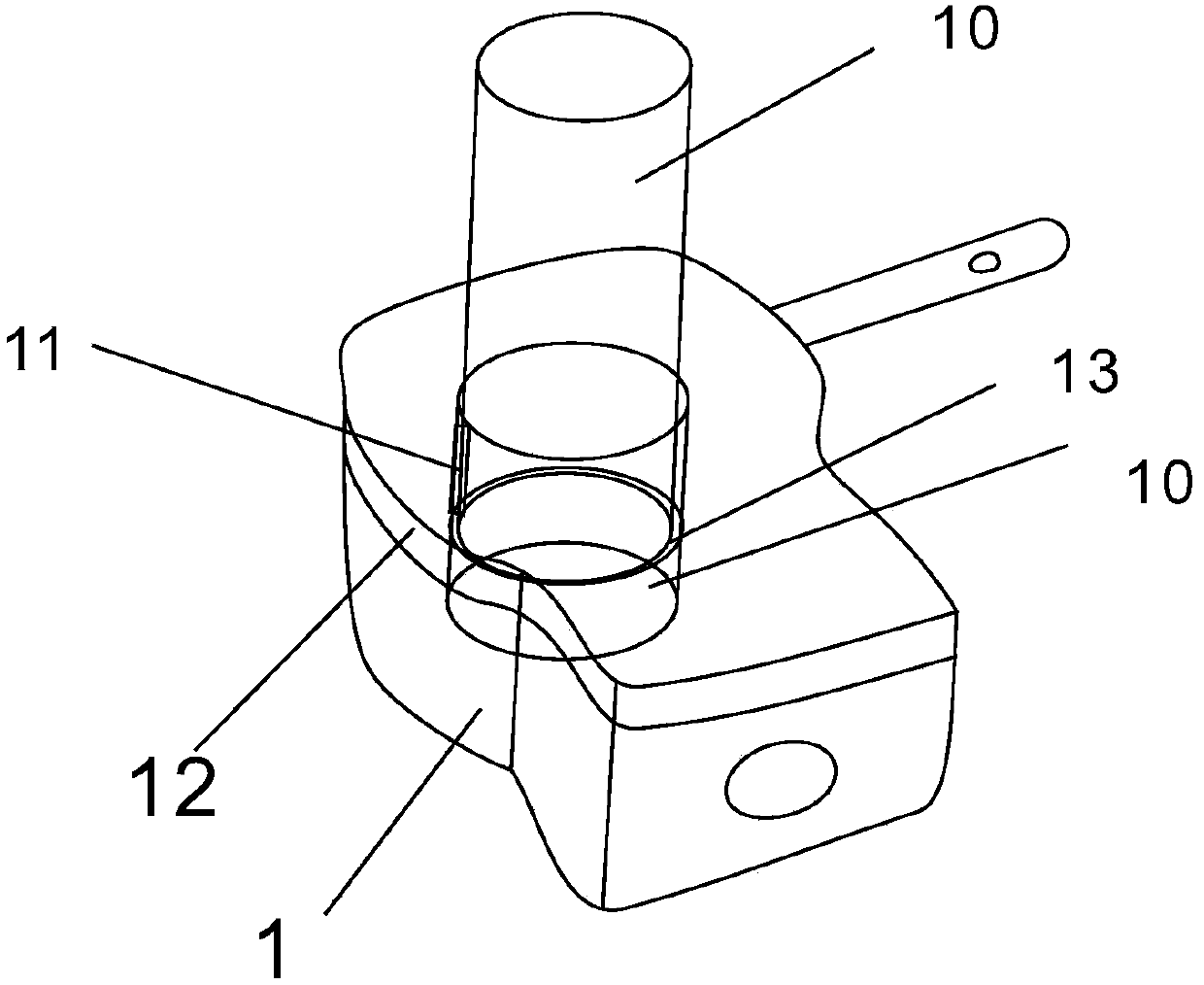

[0014] Such as figure 1 As shown, the present invention includes a box body 1 and a box cover 12; a half-cycle gear worm wheel 5 is arranged in the axial direction in the box body, and is rotatably matched with a worm screw 2 provided on the upper part of the box body, and a control signal double switch is provided at the lower part of the box body 7. The center of the worm wheel is provided with a worm shaft hole 10, and the two sides of the box body are correspondingly provided with limit jackscrews 9, and the radial center of the semicircular gear worm wheel is provided with a circumferential non-closed limit groove 6, and the limit The top wire is limited in the non-closed limit groove around the circumference, and c...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap