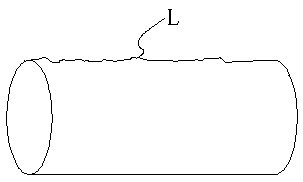

Roller generatrix rough profile detection device and method of cylindrical roller bearings

A technology of cylindrical roller bearings and detection devices, applied in the direction of electric/magnetic roughness/irregularity measurement, measurement devices, electromagnetic measurement devices, etc., can solve the problem of inconvenient operation and unsatisfactory convenience, high-efficiency bearing precision detection and detection Unreliable accuracy and other issues, to achieve the effect of increasing versatility, efficient bearing precision inspection work, and avoiding narrow operating space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

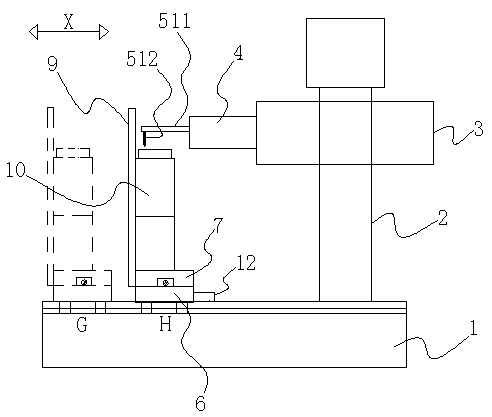

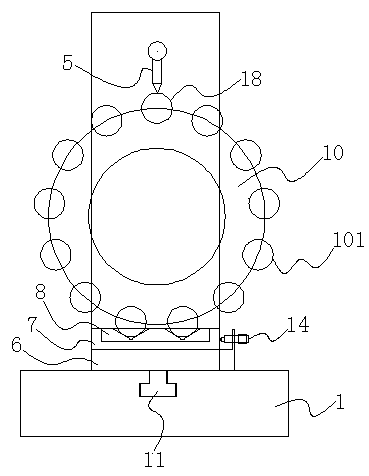

[0036] Example: such as Figure 2 to Figure 4As shown, a roller generatrix roughness profile detection device of a cylindrical roller bearing includes a surface roughness profile measuring instrument and a bearing clamping and positioning device for installing the bearing to be tested after the outer ring is removed; the surface roughness profile The measuring instrument includes a base 1, a column 2 arranged on the base 1, a driving electric box 3 arranged on the column 2, an inductive sensor 4 arranged on the driving electric box 3, and a measuring instrument arranged on the inductive sensor 4. Needle 5, the bearing clamping and positioning device includes an X-axis workbench 6, a Y-axis workbench 7, a bearing positioning fixture 8 and a bearing baffle 9, and the X-axis workbench 6 is slidably connected to the surface roughness profile measuring instrument On the base 1 and the X-axis table 6 can move back and forth on the base 1 along the X-axis. The Y-axis table 7 is slida...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com