Backing-independent type acoustic impedance test method for acoustic coating

A technology of acoustic covering layer and testing method, applied in the direction of measuring mechanical impedance, measuring ultrasonic/sonic wave/infrasonic wave, measuring device, etc., which can solve problems such as troublesome testing process, limited thickness of rigid backing, and error in measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0036] The present invention mainly comprises the following steps:

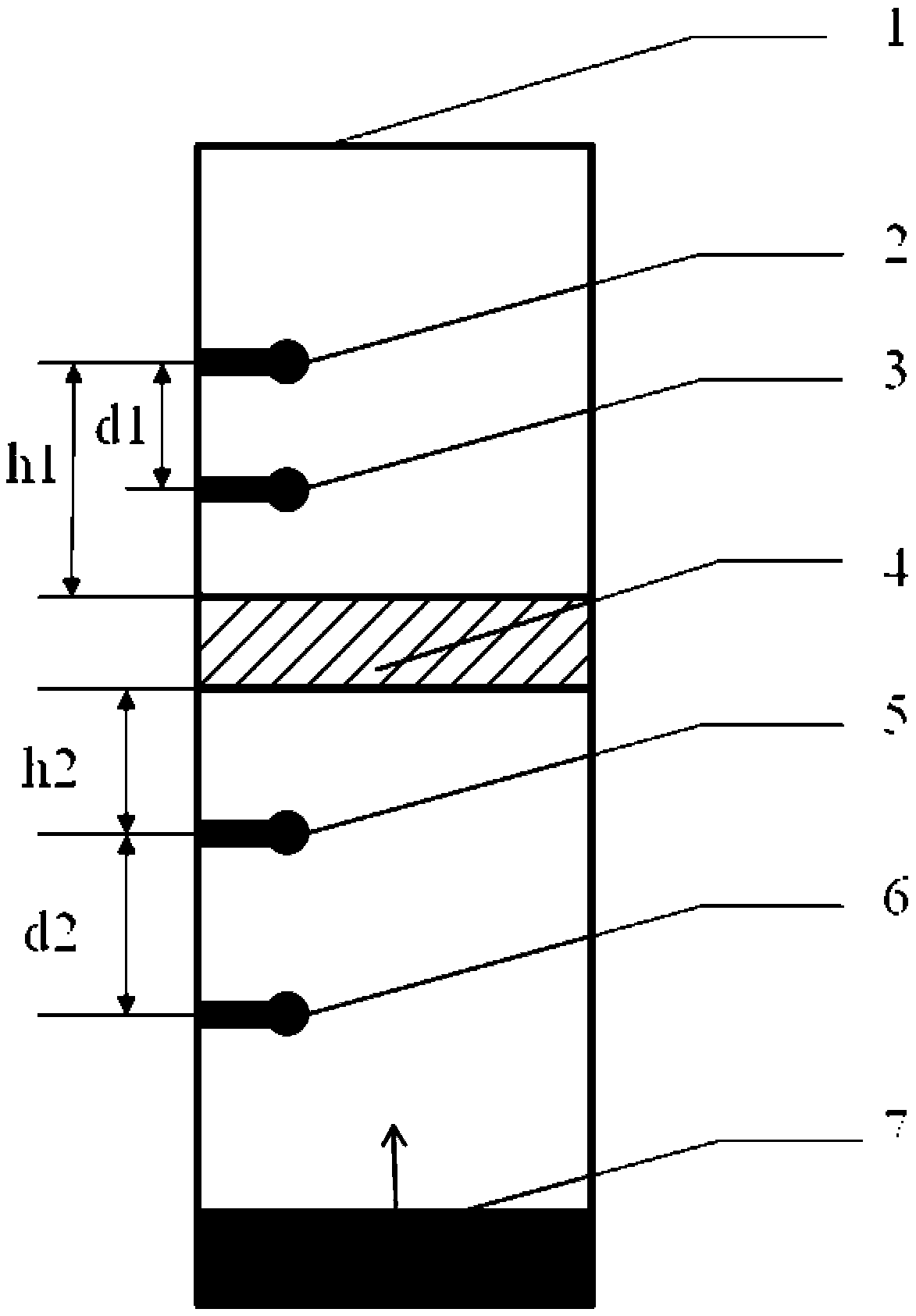

[0037] Step 1, take a typical uniform rubber layer sample as the acoustic cover layer sample, such as figure 1 As shown, the acoustic coating sample 4 is placed in the middle of the tube body in the hydroacoustic plane acoustic waveguide. There is a certain liquid column height (more than 1m in the present embodiment). One end (lower end in this embodiment) of the tube body cavity of the hydroacoustic plane acoustic waveguide is provided with a transmitting transducer 7, and two hydrophones are arranged between the transmitting transducer 7 and the acoustic coating sample 4: 3# water Hearing device 5, 4# hydrophone 6, two hydrophones are arranged between the liquid surface 1 on the acoustic cover sample 4 hydroacoustic plane acoustic waveguide: 1# hydrophone 2, 2# hydroph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com