Polymer plastic melt flowing rate meter

A melt flow rate and polymer technology, applied in the measurement of DC flow characteristics, etc., can solve the problems of shortening the service life of the cutting knife, unsatisfactory heat preservation effect, affecting the measurement results, etc., to enhance the heat preservation effect, avoid a large amount of loss, The effect of increasing the measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

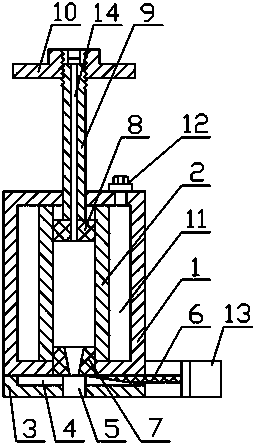

[0010] The present invention includes a heat preservation shell 1, a heating barrel 2, a knife plate 3, a knife groove 4, a discharge port 5, a cutting knife 6, a die 7, a piston 8, a connecting rod 9, a weight seat 10, and a vacuum heat preservation chamber 11. Vacuumizing port 12, pneumatic control element 13, and air pumping channel 14. When installing, first set the vacuuming port 12 on the heat-insulating shell 1, and then install the heating barrel 2 inside the heat-insulating shell 1. At this time A vacuum insulation cavity 11 is formed between the heat preservation shell 1 and the heating barrel 2, the die 7 is installed on the bottom of the heating barrel 2, and the knife groove 4 and the discharge port 5 are set inside the knife plate 3, and then the knife The plate 3 is installed at the lower end of the heat preservation shell 1, the cutting knife 6 is installed in the knife groove 4 through the pneumatic control element 13, and the air extraction channel 14 is opene...

Embodiment 2

[0012] When in use, first add an appropriate amount of polymer plastic particles into the heating barrel 2, then install the piston 8 in the heating barrel 2, turn on the power, the heating barrel 2 heats the polymer plastic particles to melt them, and passes through the air pumping channel 14 After extracting the gas in the melt, put the weight on the weight base 10, and start timing at this time, the pressure of the weight makes the piston 8 move downward, and the melt is squeezed and flows out from the die 7, reaching At a predetermined time, the pneumatic control element 13 controls the cutting knife 6 to move laterally to cut off the melt, and weighs the cut melt to complete the measurement process of the entire melt flow rate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com