Real-time monitoring method for shrinkage volume of epoxy resin in curing process

A technology of epoxy resin curing and real-time monitoring, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve problems such as inapplicability, and achieve the effects of wide applicability, high test accuracy, and simple experimental devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

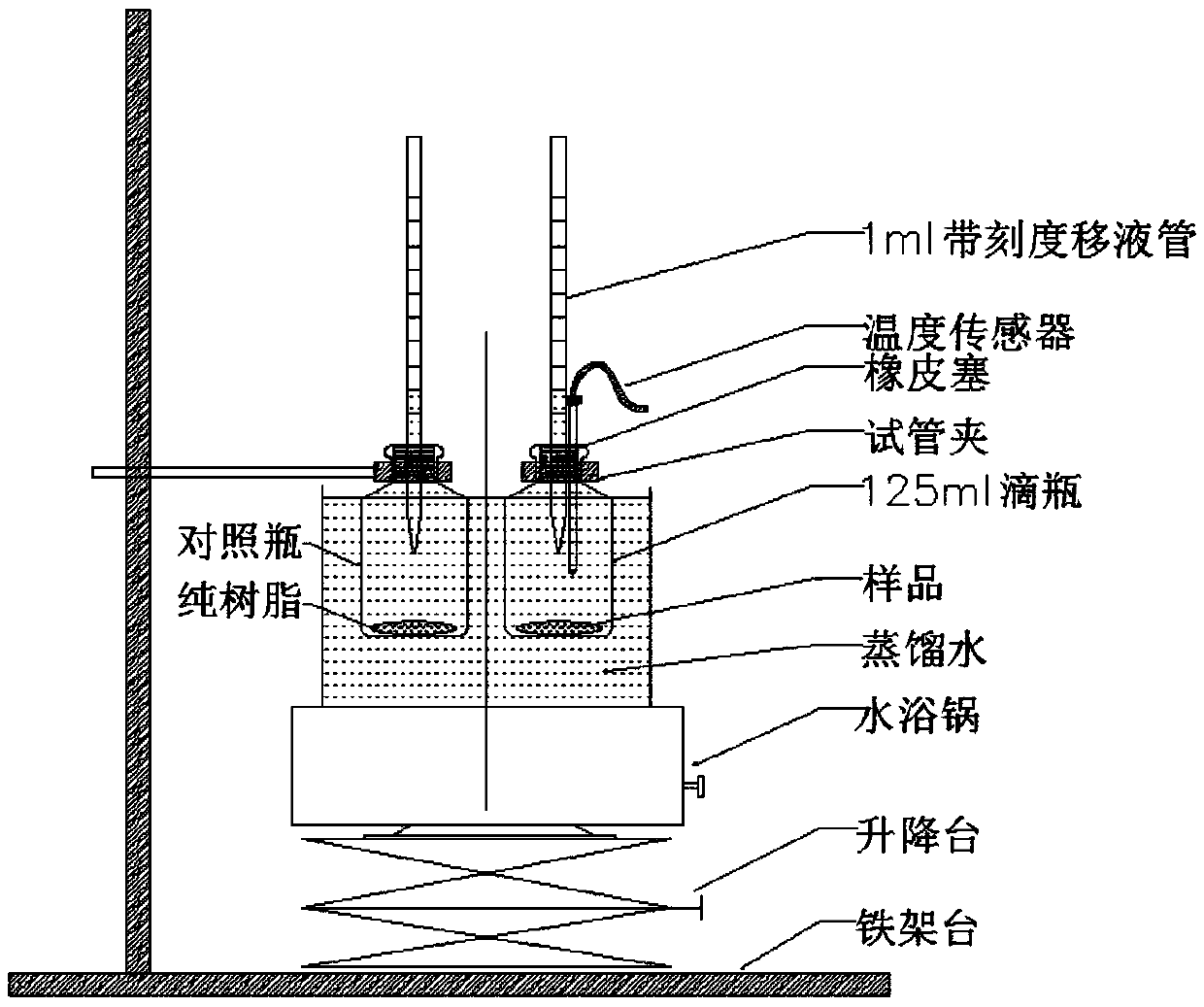

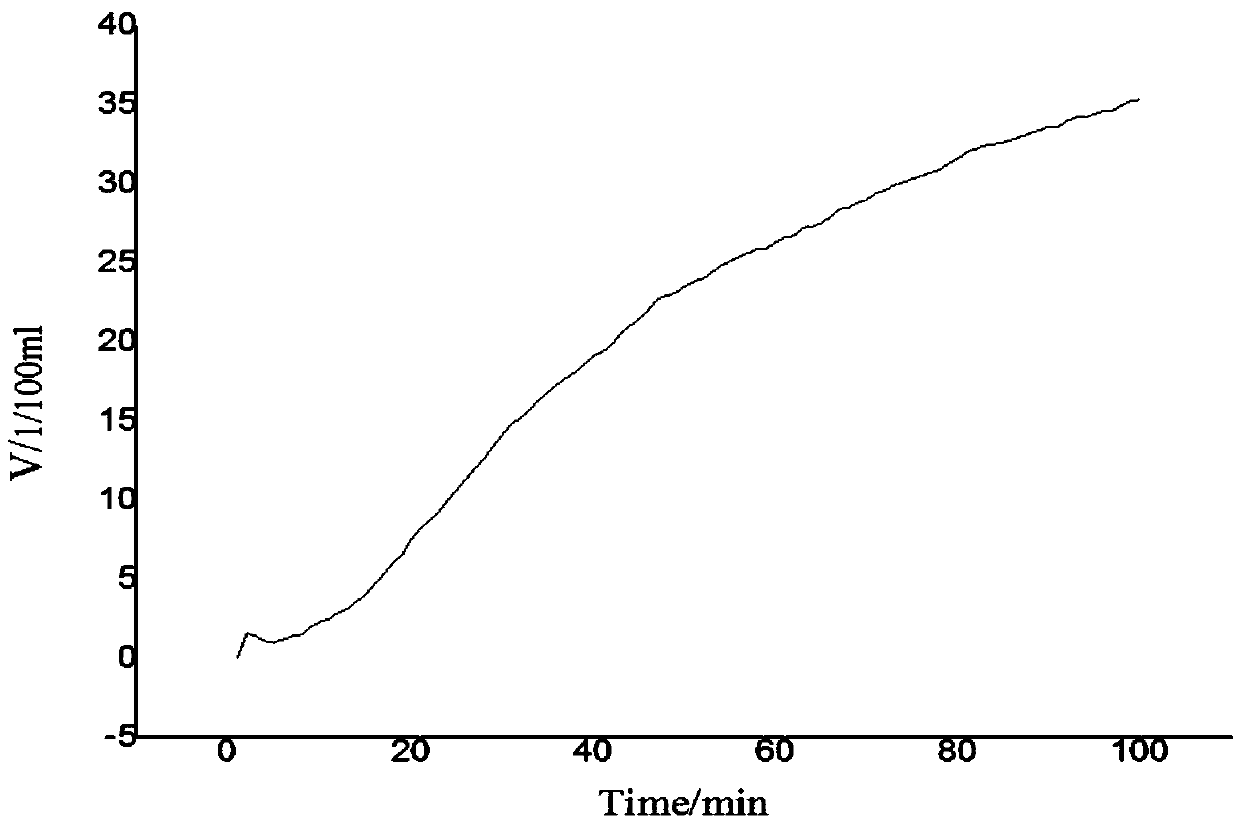

[0035] A method for real-time monitoring of chemical shrinkage during epoxy resin curing, comprising the following steps:

[0036] (1) Fill the drop bottle equipped with a pipette (cleaned and dried in advance) and a temperature sensor with water into the water bath, fix it with a test tube clamp, then raise the temperature of the water bath to 60°C, and keep it warm for 5-10 minutes;

[0037] (2) Mix the epoxy resin system evenly in proportion, then use a vacuum oven to evacuate for 10 minutes, weigh 8.320g of resin and put it into a PE bag, drain the air inside the PE bag, and seal it with nylon rope. Use the same treatment method, weigh and pack in equal amounts;

[0038] (3) Then put the PE bag containing the sample and the resin PE bag of the control group into two droppers respectively at the same time, tighten the rubber stopper, and adjust the height of the liquid column in the pipette so that it is close to the 0 scale line;

[0039] (4) Start timing at the moment of...

Embodiment 2

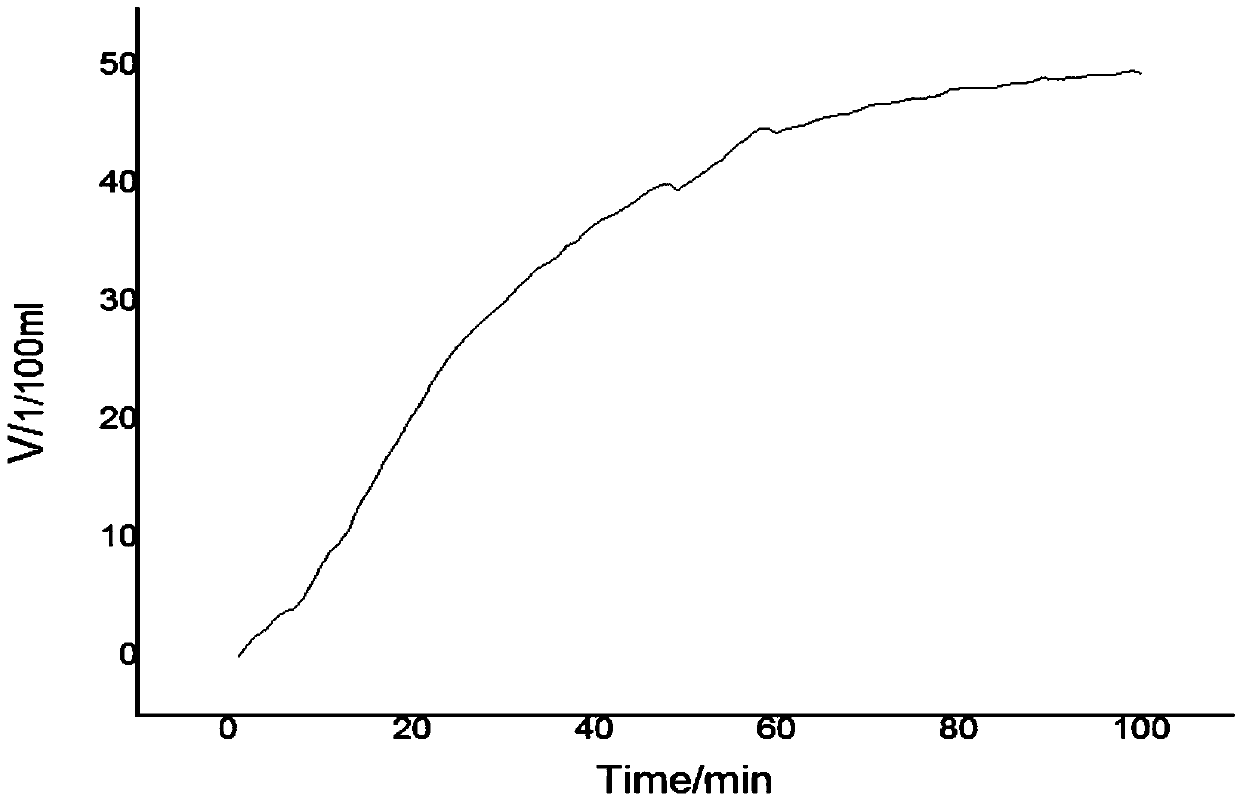

[0042] A method for real-time monitoring of chemical shrinkage during epoxy resin curing, comprising the following steps:

[0043] (1) Fill the drop bottle equipped with a pipette (cleaned and dried in advance) and a temperature sensor with water into the water bath, fix it with a test tube clamp, then raise the temperature of the water bath to 70°C, and keep it warm for 5-10 minutes;

[0044] (2) Mix the epoxy resin system evenly in proportion, then use a vacuum oven to evacuate for 10 minutes, weigh 8.332g of resin and put it into a PE bag, drain the air inside the PE bag, and use nylon rope to separate and seal it. The epoxy resin of the control group Use the same treatment method, weigh and pack in equal amounts;

[0045] (3) Then put the PE bag containing the sample and the resin PE bag of the control group into two droppers respectively at the same time, tighten the rubber stopper, and adjust the height of the liquid column in the pipette so that it is close to the 0 sca...

Embodiment 3

[0049] A method for real-time monitoring of chemical shrinkage during epoxy resin curing, comprising the following steps:

[0050] (1) Fill the drop bottle equipped with a pipette (cleaned and dried in advance) and a temperature sensor with water into the water bath, fix it with a test tube clamp, then raise the temperature of the water bath to 80°C, and keep it warm for 5-10 minutes;

[0051] (2) Mix the epoxy resin system evenly in proportion, then use a vacuum oven to evacuate for 10 minutes, weigh 8.331g of resin and put it into a PE bag, drain the air inside the PE bag, and seal it with nylon rope. Use the same treatment method, weigh and pack in equal amounts;

[0052] (3) Then put the PE bag containing the sample and the resin PE bag of the control group into two droppers respectively at the same time, tighten the rubber stopper, and adjust the height of the liquid column in the pipette so that it is close to the 0 scale line;

[0053] (4) Start timing at the moment of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com