Automatic PCB FCT testing machine and testing method thereof

A PCB board and testing system technology, applied in the field of automated PCB board FCT testing machine and its testing system, can solve the problems of further improvement of automation, high labor intensity of operators, and complicated operation process, so as to simplify the quality control process and method, improving test efficiency and accuracy, and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

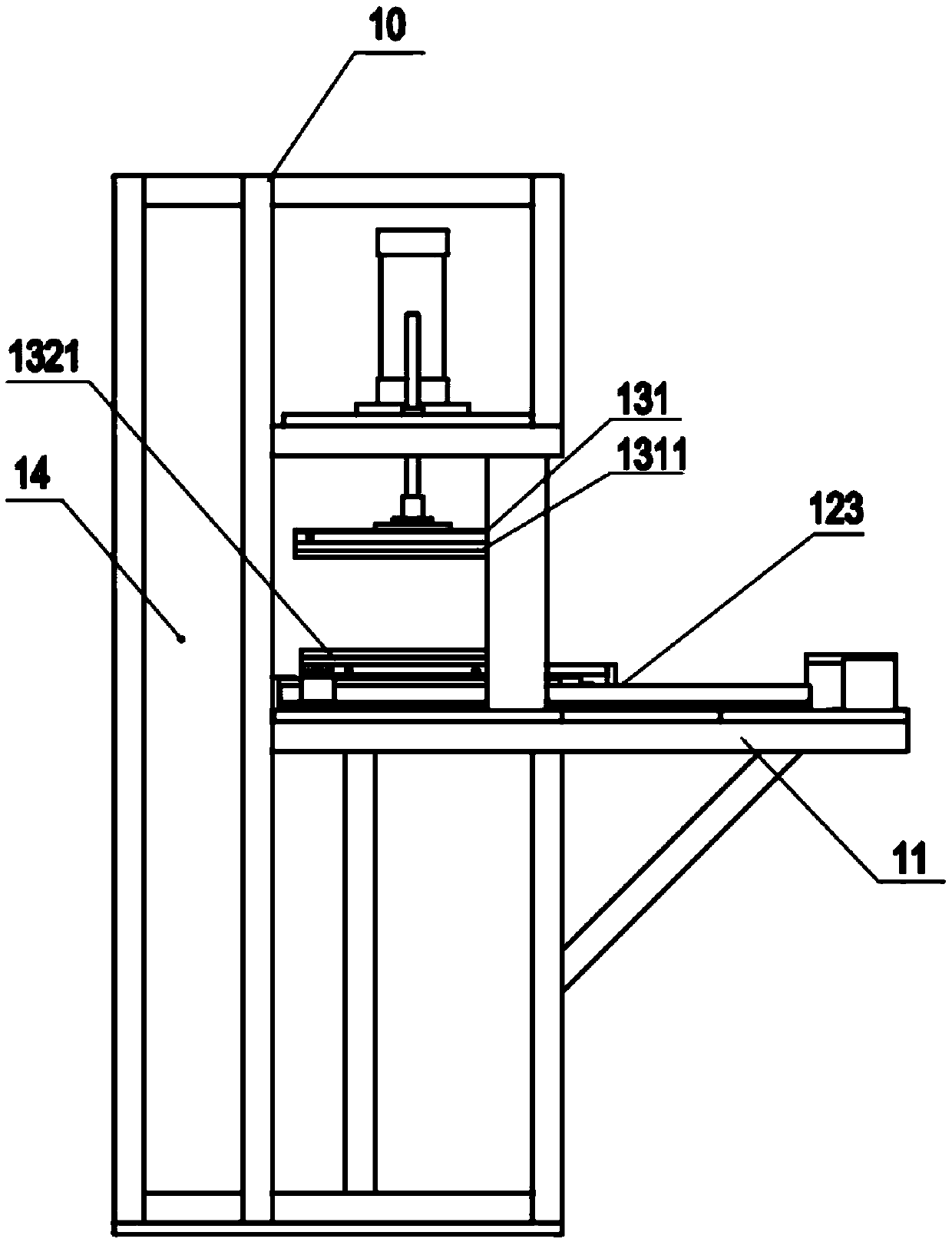

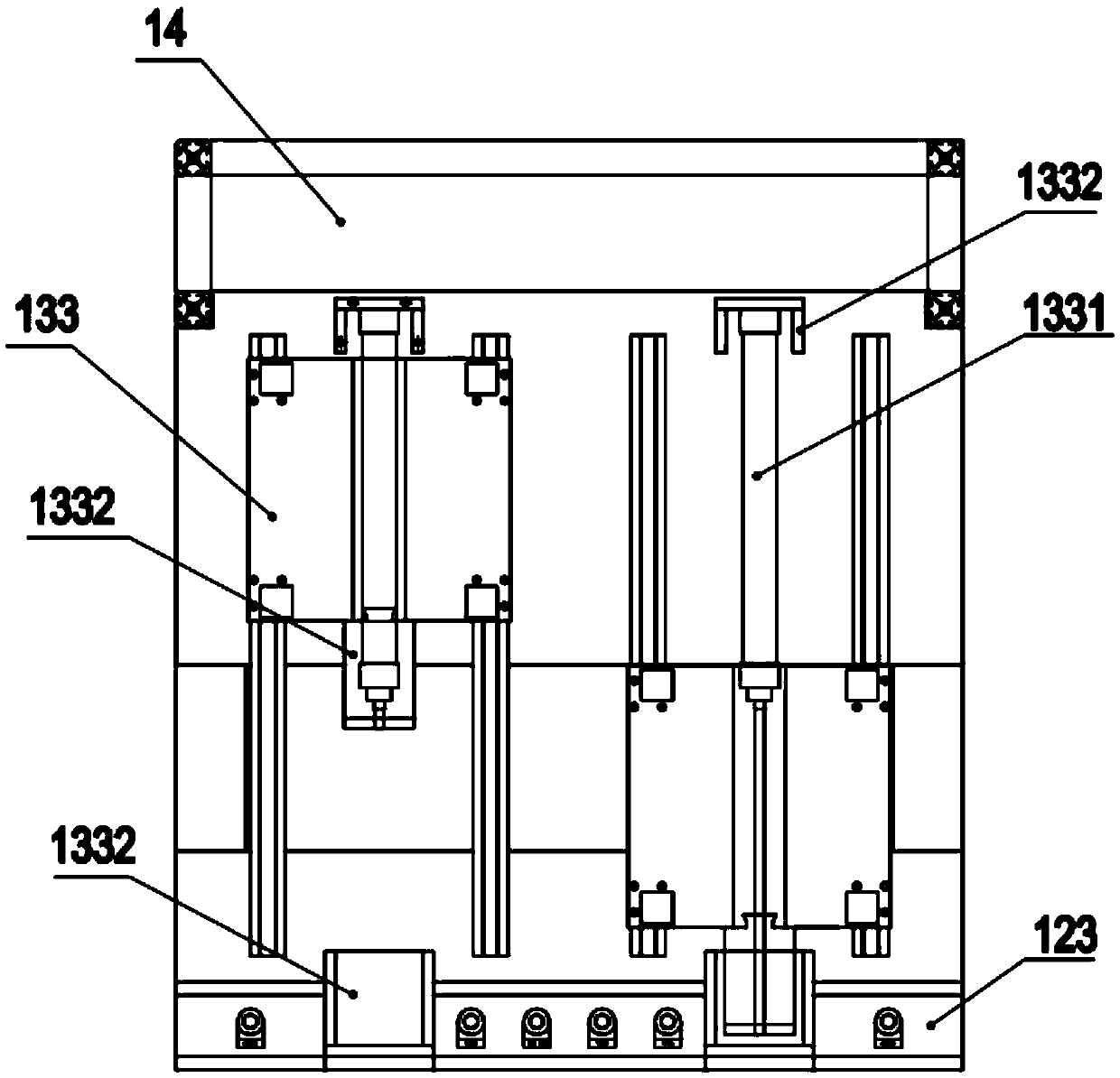

[0026] Such as Figure 1 to Figure 3 As shown, the embodiment of the present invention provides an automated PCB board FCT testing machine 1 including a rack 10, the rack 10 includes a test bench 11 and a mechanical mechanism, the mechanical mechanism is located in the The console 12 and the operation cavity 13 above the test bench 11, wherein the operation cavity 13 is provided with two left and right test fixtures, and the test fixtures include:

[0027] The upper mold pressing mechanism 131 is connected to the upper end of the frame 10 and is provided with a fixture upper mold 1311, which is used to press the PCB to be tested until it contacts the fixture upper mold 1311 and is connected to the internal test circuit of the testing machine. Sexual conduction;

[0028] The lower mold sliding table mechanism 132 is arranged above the test table 11 and can slide inside and out. It includes a lower jig mold 1321 for pressing the PCB to be tested until it contacts the upper jig 1321 ...

Embodiment 2

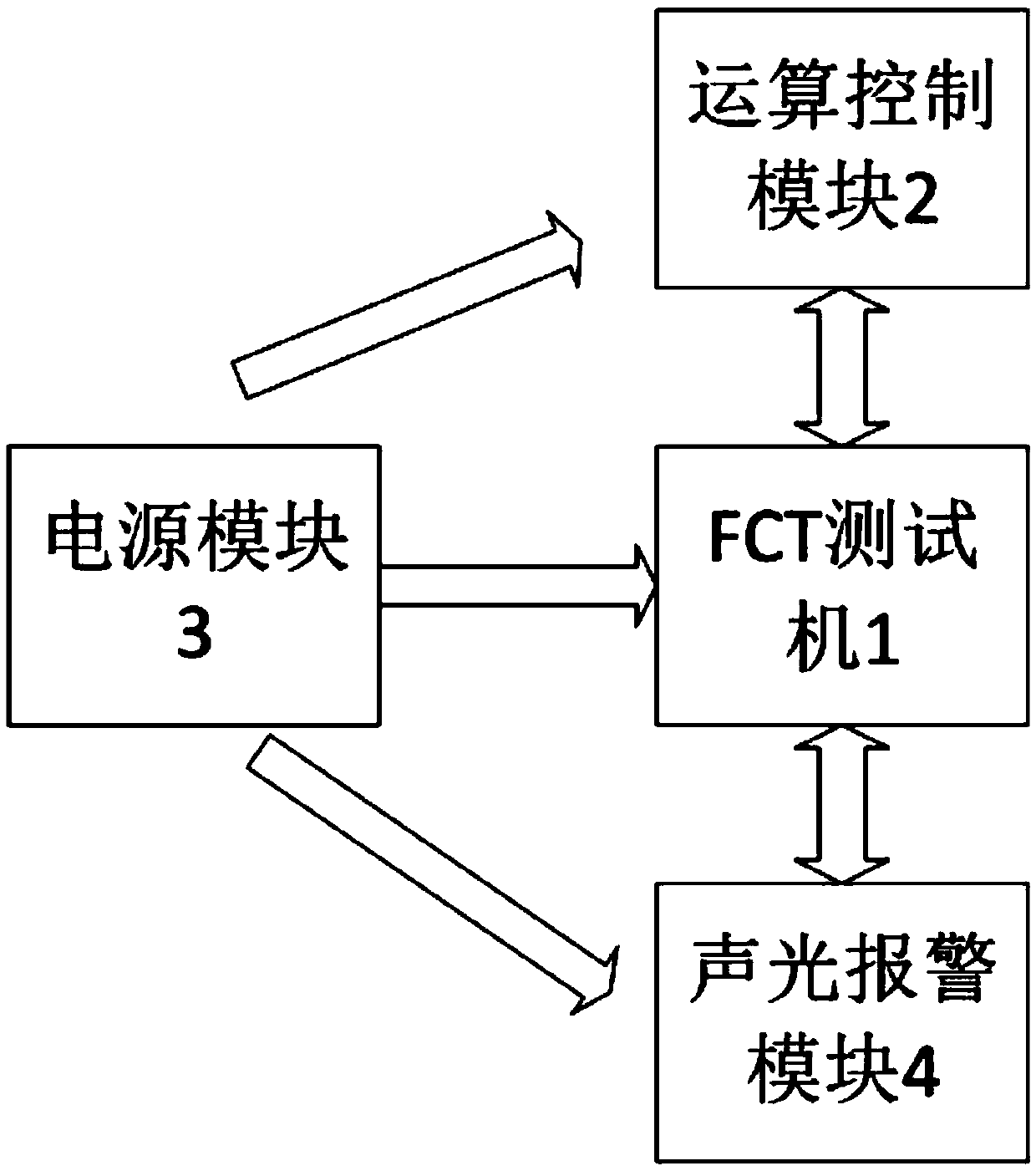

[0036] Such as Figure 4 As shown, the embodiment of the present invention provides a test system using the automated PCB board FCT tester described in the first embodiment above, and further includes an arithmetic control module 2 and a power supply module 3 connected to the FCT tester 1. In order to make the single zone test parameters (such as: including input current, voltage, active power, frequency, power factor, harmonics, etc.) unqualified, the single zone will have an audible and visual alarm. The embodiment of the present invention also includes acousto-optic The alarm module 4 is used for audible and visual alarms in a single area when the test parameters of the single area test module 121 are unqualified. And it also displays text prompts on which channel and which parameter is unqualified in the man-machine interface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com