A diffractive optical element

A diffractive optical element and laser technology, applied in optical elements, optics, instruments, etc., can solve the problems of large manufacturing error, expensive high-precision equipment, affecting the use of diffractive optical elements, etc., to achieve the effect of power compensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] combine Figure 2 to Figure 17 , which describes a specific embodiment of the present invention in detail, but does not limit the claims of the present invention in any way.

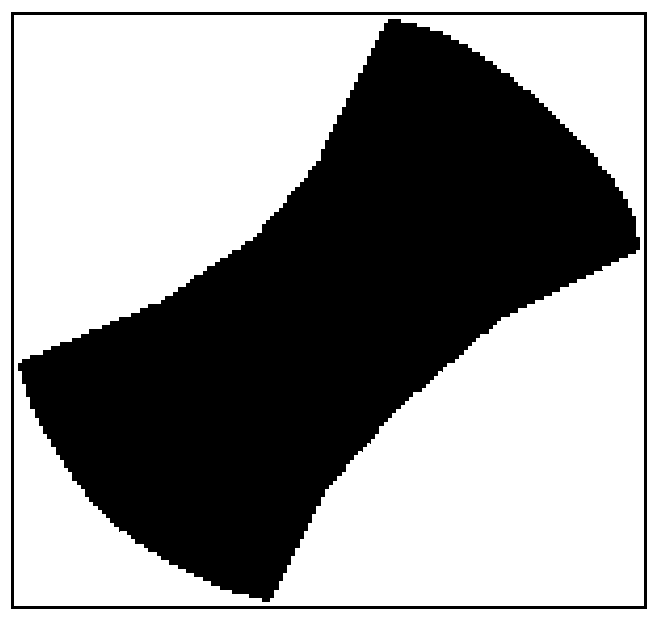

[0032] Design a diffractive optical element that conforms to 0 / c×π binary distribution, and its phase distribution is Φ(i,j), where i, j represent the position of the diffractive optical element in each cycle, i=1...n , j=1...m, such as figure 2 As shown, it is Φ(i,j) of a cycle.

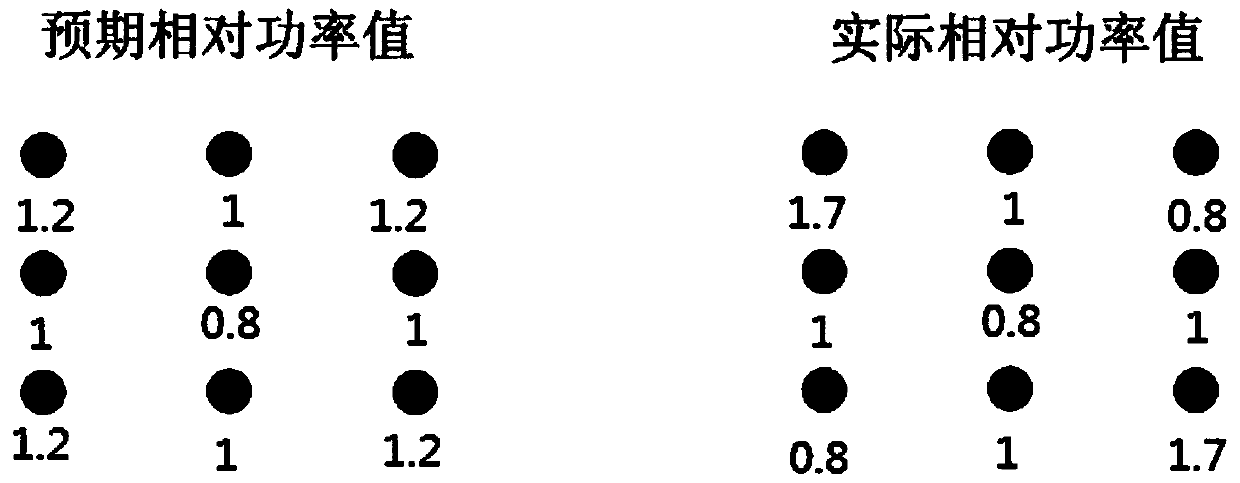

[0033] The structure adopted by this kind of diffractive optical element is usually a periodic arrangement of phase distribution Φ(i,j) (such as Image 6 As shown), such a structure makes when the manufacturing precision of the diffractive optical element is low, when the diffractive optical element splits the laser beam, the output sub-beam power is inconsistent with the expected power.

[0034] The diffractive optical element designed in the present invention includes phase distribution A and phase distribution B,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com