Control circuit of vacuum cleaner motor

A technology for controlling circuits and vacuum cleaners, applied in the control system, motor control, electrical components, etc., can solve the problems of small change, inability to increase the speed, speed increase, etc., to achieve the effect of increasing the speed, strong suction, and improving the degree of vacuum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

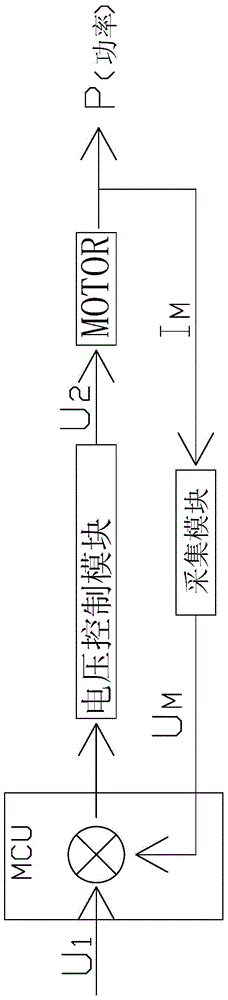

[0020] The present invention relates to a control circuit for a vacuum cleaner. Usually, the vacuum cleaner includes a motor and a control circuit, and the motor may be a DC motor or an AC motor.

[0021] Theoretically, the voltage balance equation of a DC motor is U=CeΦn+Ia(Ra+Rc), where U is the power supply voltage, Ce is the motor structure constant, Φ is the main magnetic flux of the motor, n is the motor speed, and Ia is DC motor armature current, Ra is the armature resistance, Rc is the contact resistance of the commutator (for DC brushless motor Rc is 0), according to the voltage balance equation, it can be explained that the voltage provided by the power supply is divided into two parts, that is, the part of CeΦn and the The part of Ia(Ra+Rc), in which the proportion of CeΦn is much larger than that of Ia(Ra+Rc), the part of CeΦn is used to generate the motor rotation, and the part of Ia(Ra+Rc) is used to overcome Ra+Rc to generate The voltage required for the necessa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com