Display device and production method

A display device and display area technology, applied in the field of display screens, can solve the problems of no display, failure to standardize products and design points, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] It should be understood that the specific embodiments described here are only used to explain the technology of the present invention, and are not intended to limit the technology of the present invention.

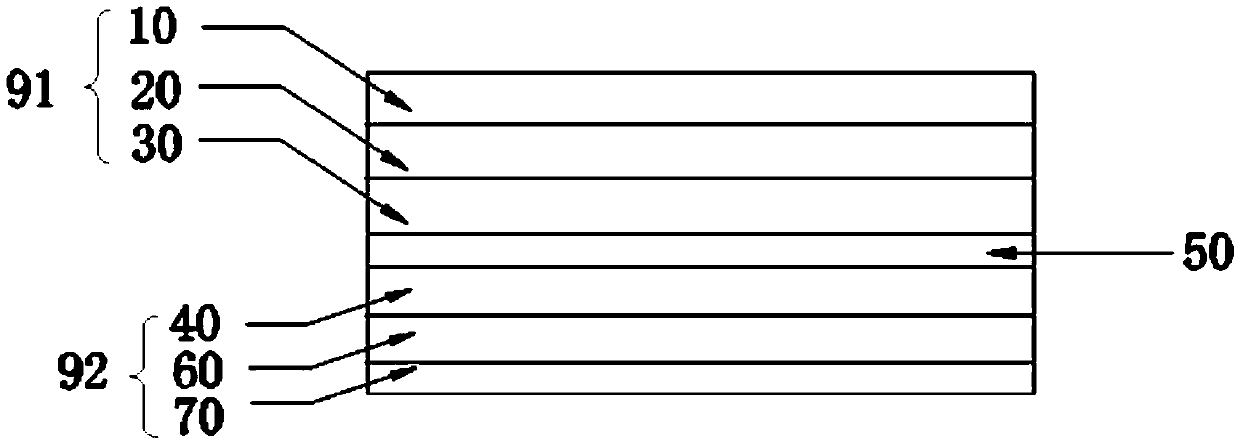

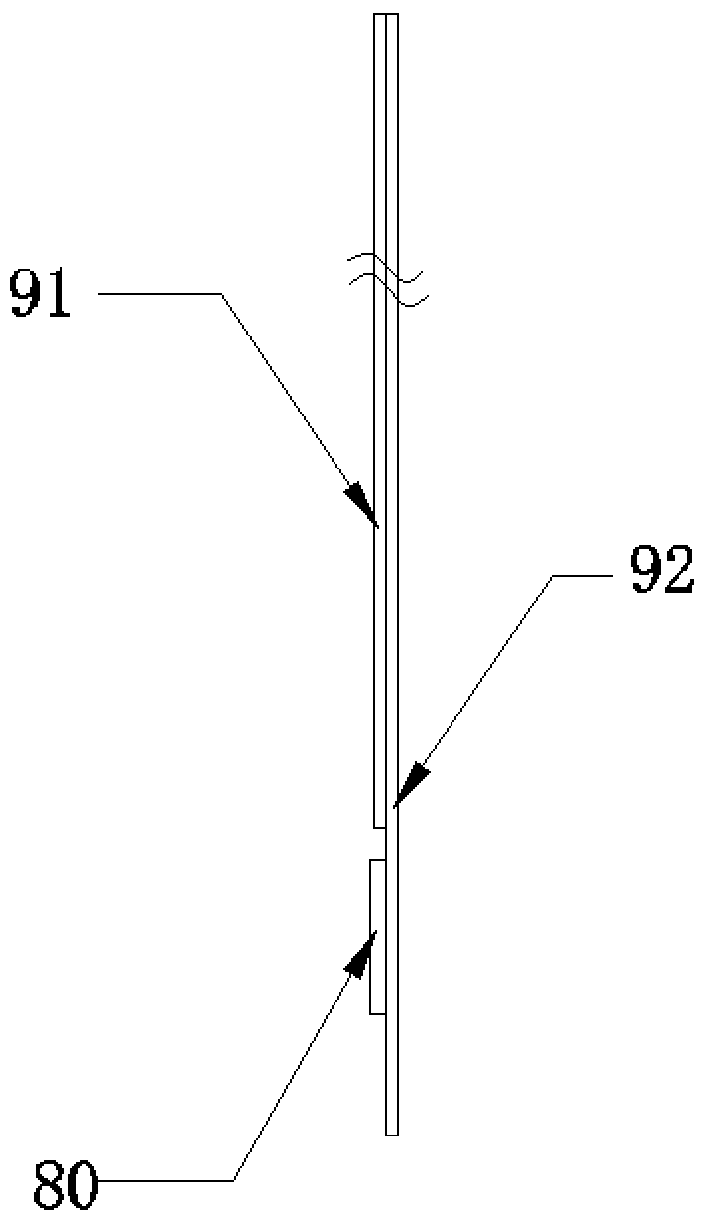

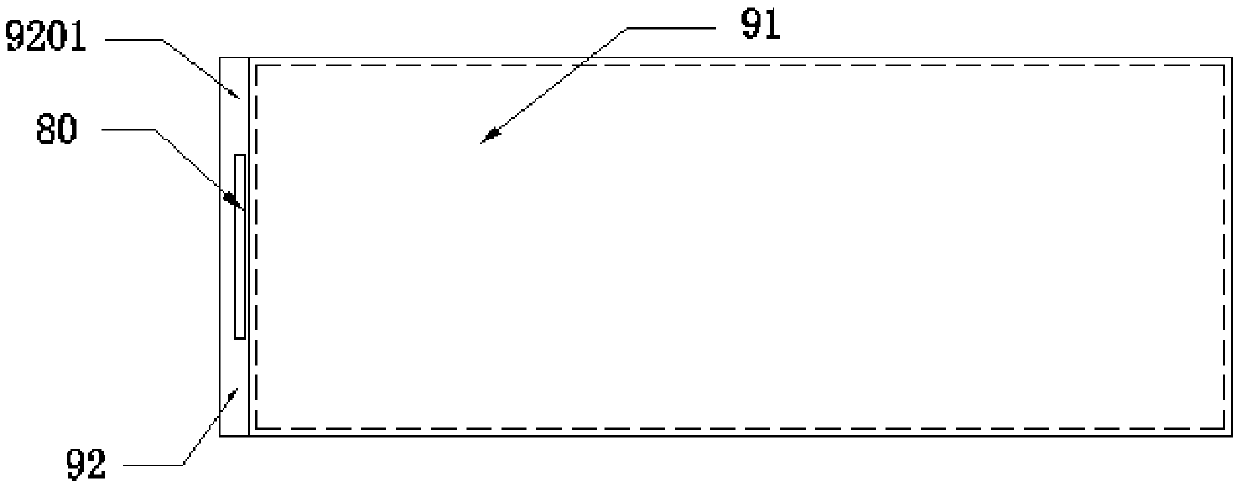

[0024] Such as Figure 1-7 Shown, in order to achieve the above object, a kind of display device mainly is made up of upper structural part (91), lower structural part (92), control IC (80); Described upper structural part (91) is made of ITO shielding layer (10 ), an upper protective body (20), a color filter layer (30) and a sequential yellow light process; (70) and sequential yellow light process; it is characterized in that: one or more spacers are arranged between the upper structure (91) and the lower structure (92), and a cavity is formed inside for storing liquid crystal And form a liquid crystal layer (50); the upper structure (91) and the lower structure (92) and the liquid crystal layer (50) are connected together by bonding; the lower protection of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com