Method for achieving rectifying tower splitting and heat coupling driven by heat transfer temperature difference

A technology of split thermal coupling and heat exchange temperature difference, which is applied in special data processing applications, instruments, electrical digital data processing, etc. It can solve the problems of inability to maximize energy saving of rectification towers and lack of thermal coupling design methods, and achieve pressure reduction requirements, energy consumption reduction, effect of reduced power requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with embodiment.

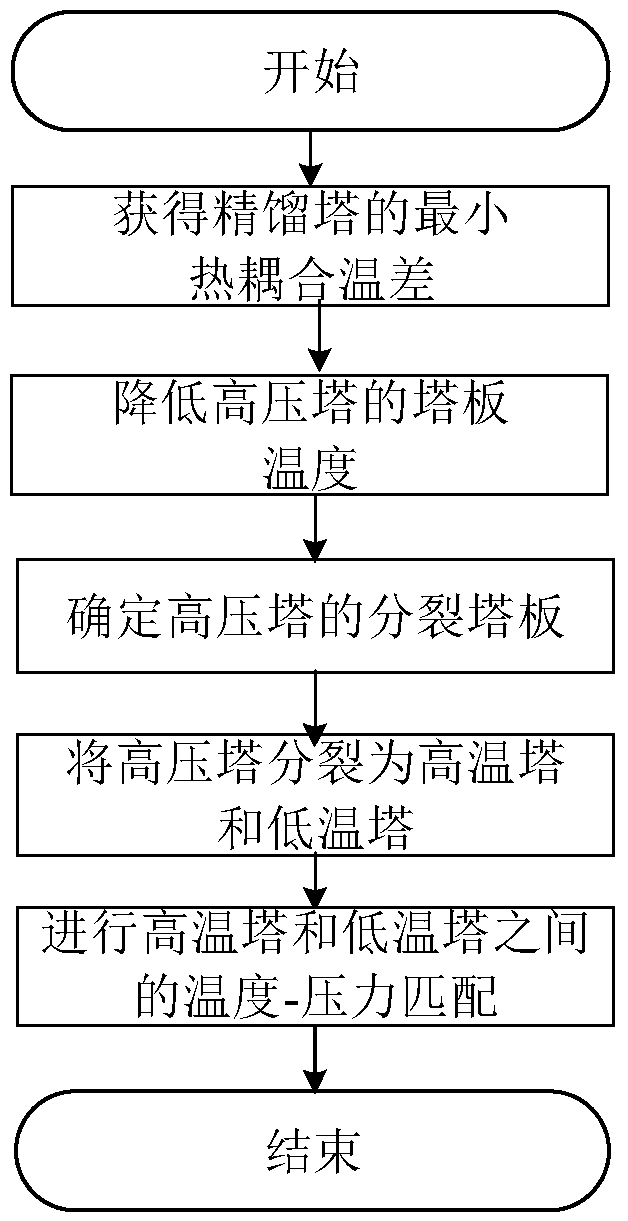

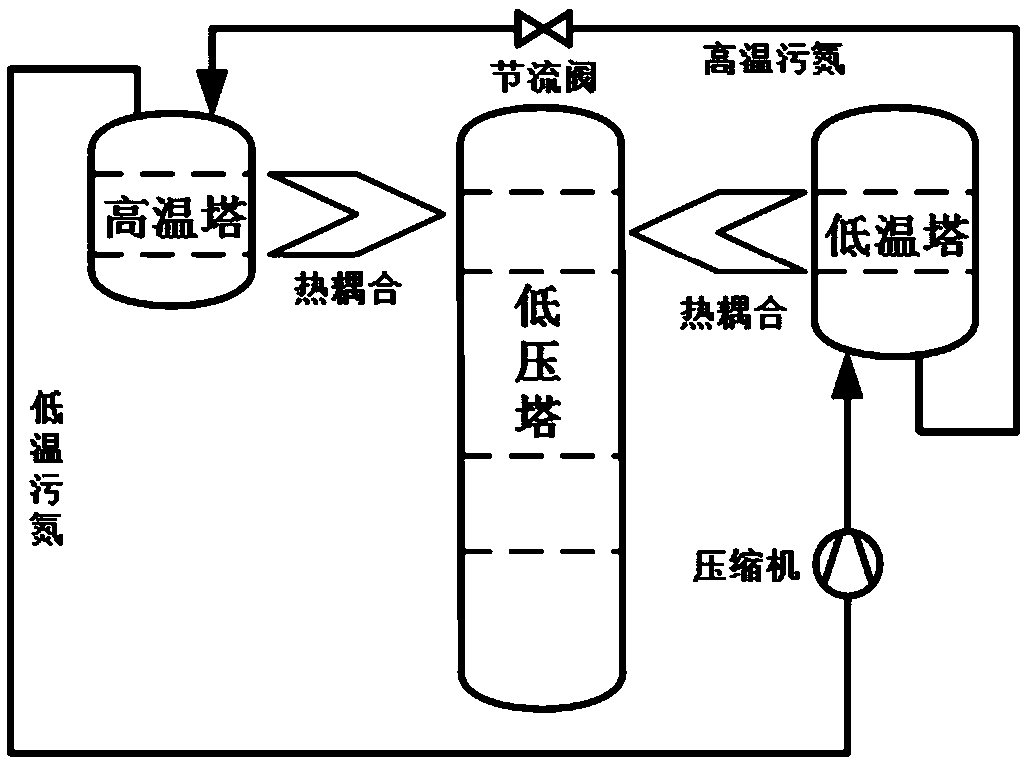

[0042] Embodiments of the present invention and processes thereof are as follows:

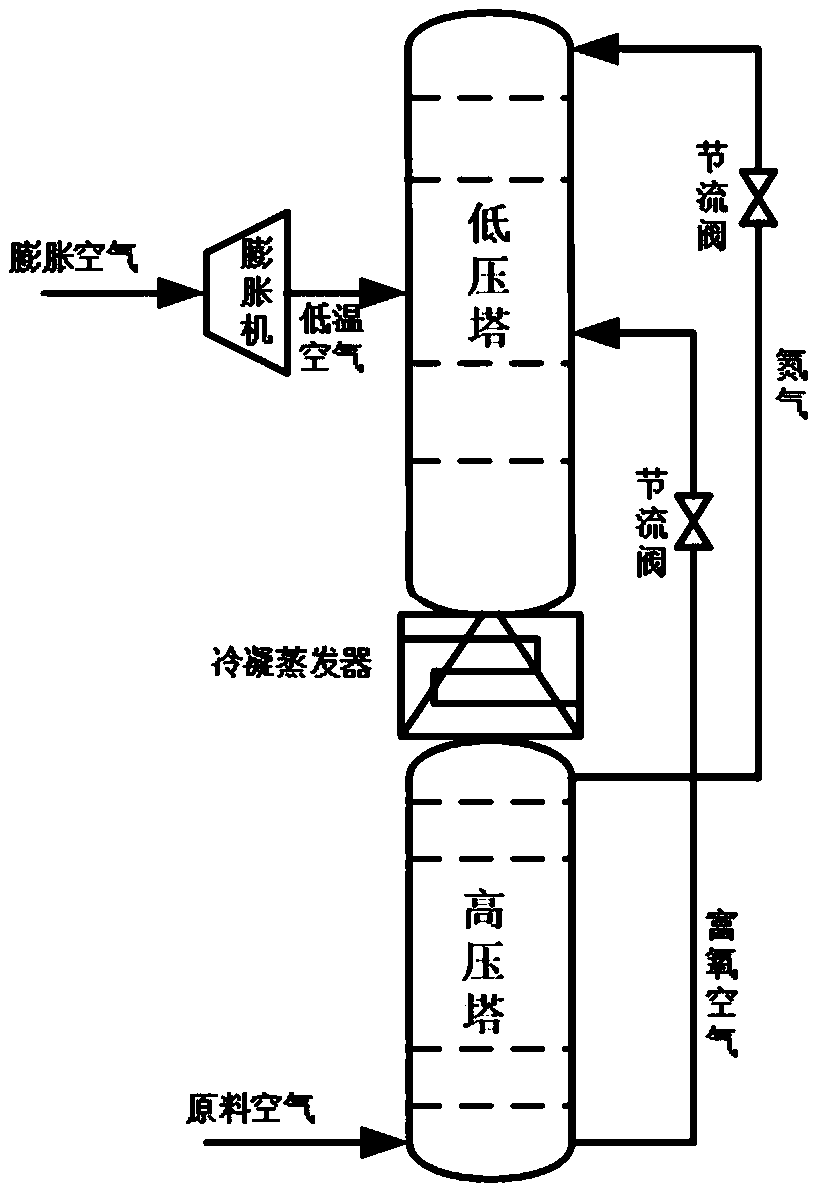

[0043] A large-scale air separation equipment rectification tower is used as the implementation object. The high-pressure tower contains 35 stages of trays, and the low-pressure tower contains 70 stages of trays.

[0044] (1) According to the plate temperature data in the single-plate coupling mode of the rectification column, the minimum thermal coupling temperature difference ΔT between the high-pressure column and the low-pressure column of the rectification column is calculated to be 1.8K.

[0045] (2) According to the temperature data of the trays at all levels in the single-plate coupling mode of the rectification tower, take the number of trays at each level of the rectification tower as the abscissa, and the tray temperature as the ordinate, draw the tray temperature curve of the rectification...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com