Processing technology for ceramic fuse tube of DC fuse installation element

A processing technology and fuse technology, applied in the processing technology field of ceramic melting tubes, can solve the problems of damaging important or valuable devices, burning circuits, and current rise, etc., achieving simple structure, enhanced strength and hardness, and simple use and maintenance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

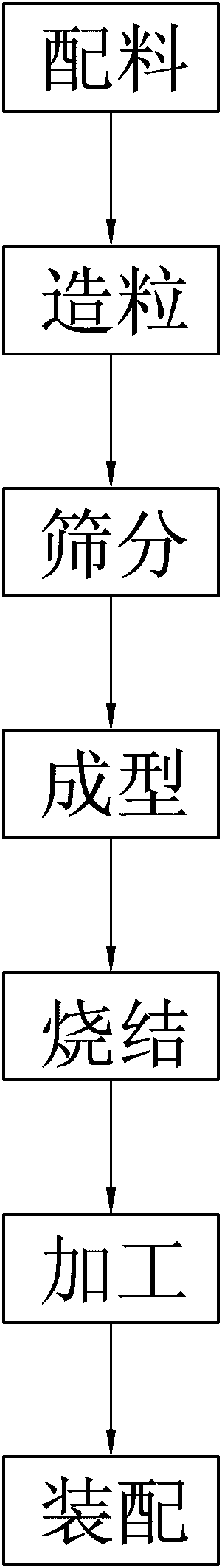

Image

Examples

Embodiment 1

[0021] Weigh raw materials by weight components: Al 2 O3, Cr2O3, SiO2, MgO and CaCO3, wherein the weight ratio of Al2O3:CaCO3:Cr2O3:SiO2 is 100:3.5:2.5:1.3, and the weight of MgO is 0.8% of the total weight of Al2O3 and Cr2O3; it will be weighed in parts by weight The raw materials are added to the granulator for granulation, and the bulk density of the granulated product is controlled: ≥1.05g / cm 3 ; The fluidity of the granulated product: ≤65 seconds / standard container; the water content of the granulated product: ≤0.15%; the glue content of the granulated product: 13%; The sieve size of the upper sieve is 60 mesh, and the sieve size of the lower sieve is 250 mesh. Take the intermediate material sieved by the double-layer sieve; put the intermediate material sieved by the double-layer sieve into the dry press for dry pressing Forming to obtain ceramic blanks; put the dry-pressed ceramic blanks into the corundum pot, and then put them into a high-temperature tunnel kiln for h...

Embodiment 2

[0023] Weigh raw materials by weight components: Al 2 O3, Cr2O3, SiO2, MgO and CaCO3, wherein the weight ratio of Al2O3:CaCO3:Cr2O3:SiO2 is 100:3.5:2.5:1.3, and the weight of MgO is 0.7% of the total weight of Al2O3 and Cr2O3; it will be weighed in parts by weight The raw materials are added to the granulator for granulation, and the bulk density of the granulated product is controlled: ≥1.05g / cm 3 ; The fluidity of the granulated product: ≤70 seconds / standard container; the water content of the granulated product: ≤0.15%; the glue content of the granulated product: 13%; The sieve size of the upper sieve is 60 mesh, and the sieve size of the lower sieve is 250 mesh. Take the intermediate material sieved by the double-layer sieve; put the intermediate material sieved by the double-layer sieve into the dry press for dry pressing Forming to obtain ceramic blanks; put the dry-pressed ceramic blanks into the corundum pot, and then put them into a high-temperature tunnel kiln for h...

Embodiment 3

[0025] Weigh raw materials by weight components: Al 2 O3, Cr2O3, SiO2, MgO and CaCO3, wherein the weight ratio of Al2O3:CaCO3:Cr2O3:SiO2 is 100:3.5:2.5:1.3, and the weight of MgO is 0.6% of the total weight of Al2O3 and Cr2O3; it will be weighed in parts by weight The raw materials are added to the granulator for granulation, and the bulk density of the granulated product is controlled: ≥1.05g / cm 3 ; The fluidity of the granulated product: ≤70 seconds / standard container; the water content of the granulated product: ≤0.15%; the glue content of the granulated product: 13%; The sieve size of the upper sieve is 60 mesh, and the sieve size of the lower sieve is 250 mesh. Take the intermediate material sieved by the double-layer sieve; put the intermediate material sieved by the double-layer sieve into the dry press for dry pressing Forming to obtain ceramic blanks; put the dry-pressed ceramic blanks into the corundum pot, and then put them into a high-temperature tunnel kiln for h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com