A piston protector

A protector, piston technology, applied in electrical components, electromechanical devices, structural connections, etc., can solve the problems of O-ring damage, unreasonable structural design, loss of protective effect of the protector, etc., and achieve the effect of preventing damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

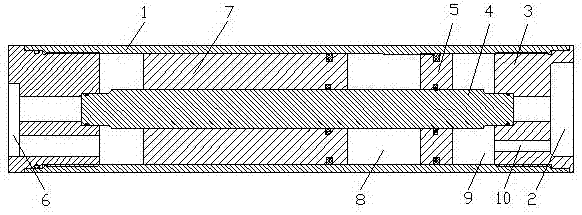

[0042] See figure 1 , A piston protector, comprising a housing 1 and a support 3 connected to the internal medium cavity 2, the support 3 is fixed on the housing 1, and also includes a piston rod 4 fixed on the support 3, the piston rod 4 is located In the housing 1, a first piston 5 and a second piston 7 communicating with an external medium cavity 6 are connected between the piston rod 4 and the housing 1 through a sealing ring. The first piston 5, the second piston 7, The housing 1 and the piston rod 4 enclose a transition cavity 8. The first piston 5, the housing 1, the piston rod 4 and the support 3 enclose a thin oil chamber 9, and the support 3 is provided with an oil through hole 10 , The oil through hole 10 communicates with the thin oil cavity 9 and the internal medium cavity 2 respectively.

[0043] This embodiment is the most basic implementation. The piston rod is located in the housing. The first piston and the second piston communicating with the external medium ca...

Embodiment 2

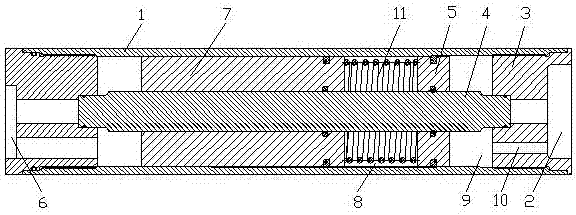

[0045] See figure 2 , A piston protector, comprising a housing 1 and a support 3 connected to the internal medium cavity 2, the support 3 is fixed on the housing 1, and also includes a piston rod 4 fixed on the support 3, the piston rod 4 is located In the housing 1, a first piston 5 and a second piston 7 communicating with an external medium cavity 6 are connected between the piston rod 4 and the housing 1 through a sealing ring. The first piston 5, the second piston 7, The housing 1 and the piston rod 4 enclose a transition cavity 8. The first piston 5, the housing 1, the piston rod 4 and the support 3 enclose a thin oil chamber 9, and the support 3 is provided with an oil through hole 10 , The oil through hole 10 communicates with the thin oil cavity 9 and the internal medium cavity 2 respectively.

[0046] An elastic element 11 is installed in the transition cavity 8.

[0047] The elastic element 11 is a spring, one end of the spring is connected to the first piston 5, and th...

Embodiment 3

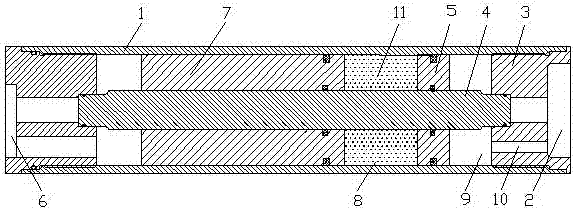

[0050] See image 3 , A piston protector, comprising a housing 1 and a support 3 connected to the internal medium cavity 2, the support 3 is fixed on the housing 1, and also includes a piston rod 4 fixed on the support 3, the piston rod 4 is located In the housing 1, a first piston 5 and a second piston 7 communicating with an external medium cavity 6 are connected between the piston rod 4 and the housing 1 through a sealing ring. The first piston 5, the second piston 7, The housing 1 and the piston rod 4 enclose a transition cavity 8. The first piston 5, the housing 1, the piston rod 4 and the support 3 enclose a thin oil chamber 9, and the support 3 is provided with an oil through hole 10 , The oil through hole 10 communicates with the thin oil cavity 9 and the internal medium cavity 2 respectively.

[0051] An elastic element 11 is installed in the transition cavity 8.

[0052] The elastic element 11 is gas, and the gas fills the transition cavity 8.

[0053] This embodiment is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com