Enthalpy exchanger element and method of manufacture

A technology of exchangers and components, applied in the field of enthalpy exchanger components and making enthalpy exchanger components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

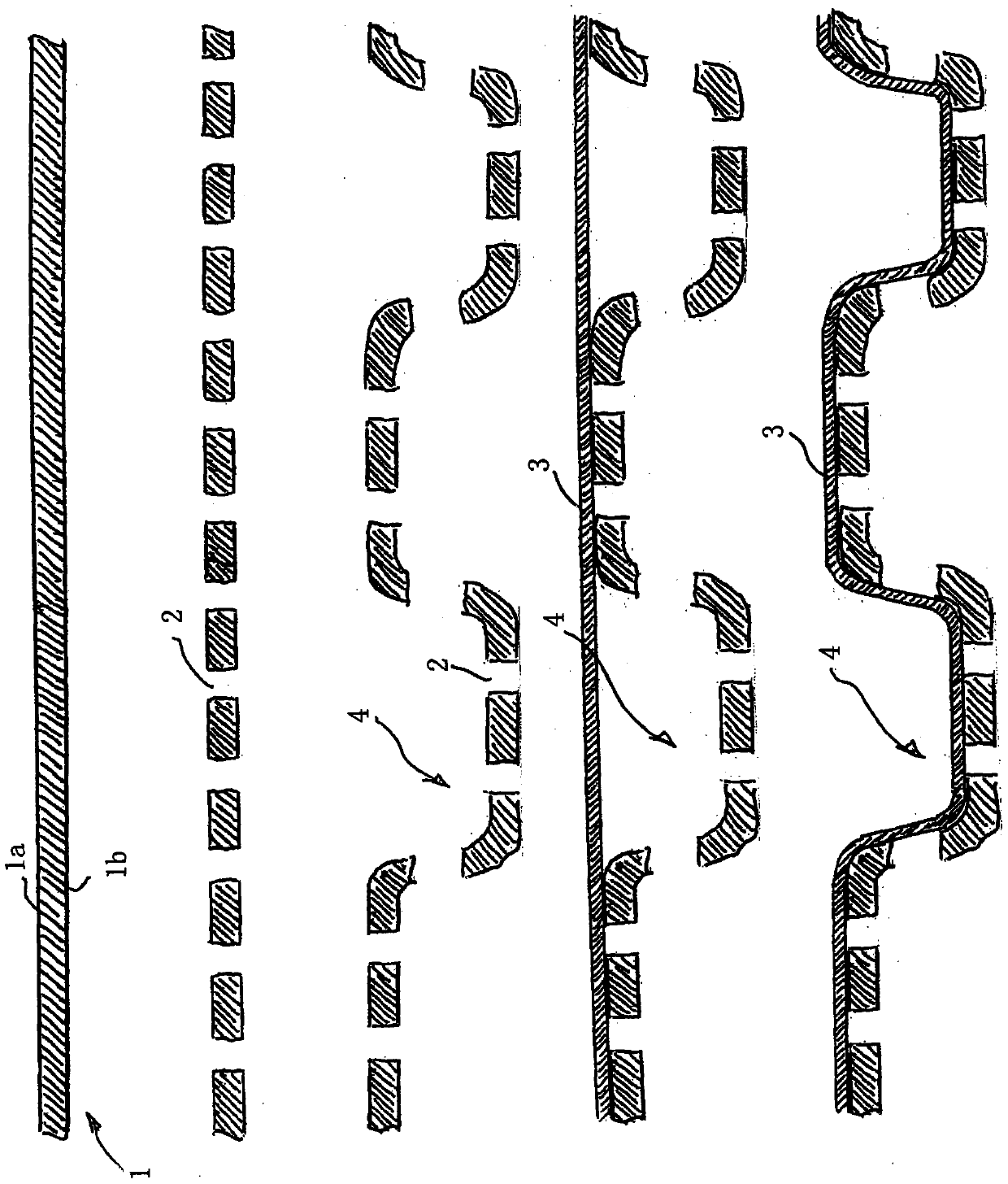

[0052] exist figure 1 In , the sequence of steps of the fabrication method according to the present invention is shown. figure 1 Each step shown in corresponds to figure 2 The resulting state shown schematically in . It should be noted that figure 2 Geometric parameters such as thickness, pore diameter, curvature, etc. described in are for exemplary purposes only. Accordingly, they do not necessarily indicate suitable or preferred ratios for these parameters.

[0053] In a providing step S1 a flat but unshaped sheet metal element 1 with defined outer dimensions is provided. In the piercing step S2, a part of the flat sheet metal element 1 is passed to a piercing device (not shown), where the flat sheet metal element 1 is punched by a punching die (not shown) selected according to the size of the hole required. shown) perforation. In the present case, the entire plate element 1 is perforated with a symmetrical hole pattern, except for border areas (not shown), to allow ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com