Disassembling and assembling device for parallel dual-supporting roller shaft bearings

A double support and bearing seat technology, applied in the direction of metal rolling mill stand, metal rolling, metal rolling stand, etc., can solve the problems of safety accidents, bumps, thick diameter of backup rolls, etc., to reduce labor intensity, Improve disassembly and assembly efficiency and avoid damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

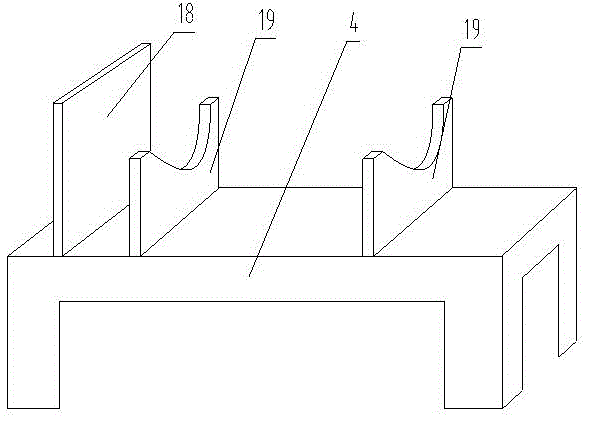

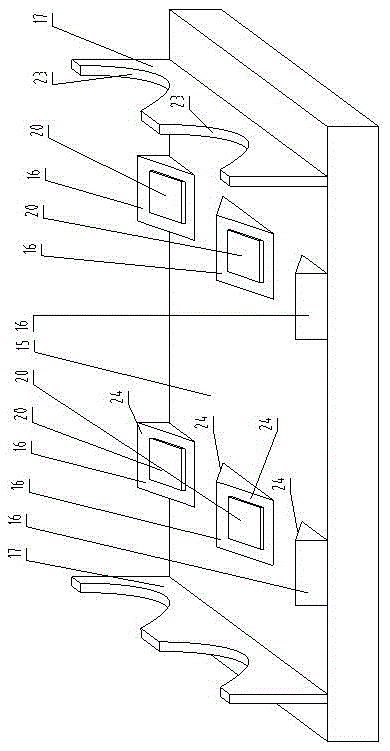

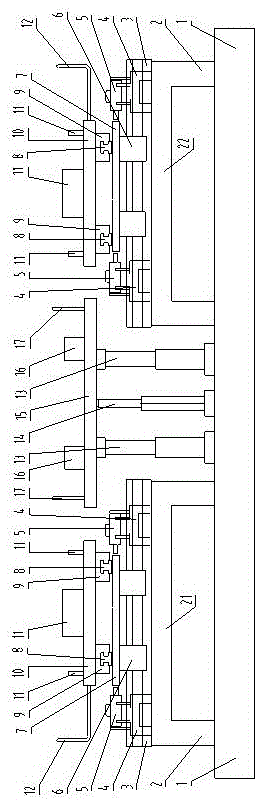

[0019] Such as figure 1 As shown, the side-by-side double support roller bearing seat dismounting device of the present invention includes a base 1, a bearing seat dismounting trolley located on the left and right sides of the base 1, and a double support roller lifting trolley located in the middle of the base 1. The two bearing seat dismounting trolleys are the left bearing seat dismounting trolley 21 and the right bearing seat dismounting trolley 22, and the left bearing seat dismounting trolley 21 and the right bearing seat dismounting trolley 22 are arranged symmetrically. , the double support roller lifting trolley is located in the middle of the two bearing housing disassembly and assembly trolleys; the bearing housing disassembly and assembly trolley includes a support platform 2, and more than two second slide rails 3 are horizontally arranged on the support platform 2, and the support platform 2 A hydraulic cylinder support base 4 is fixedly connected to the left and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com