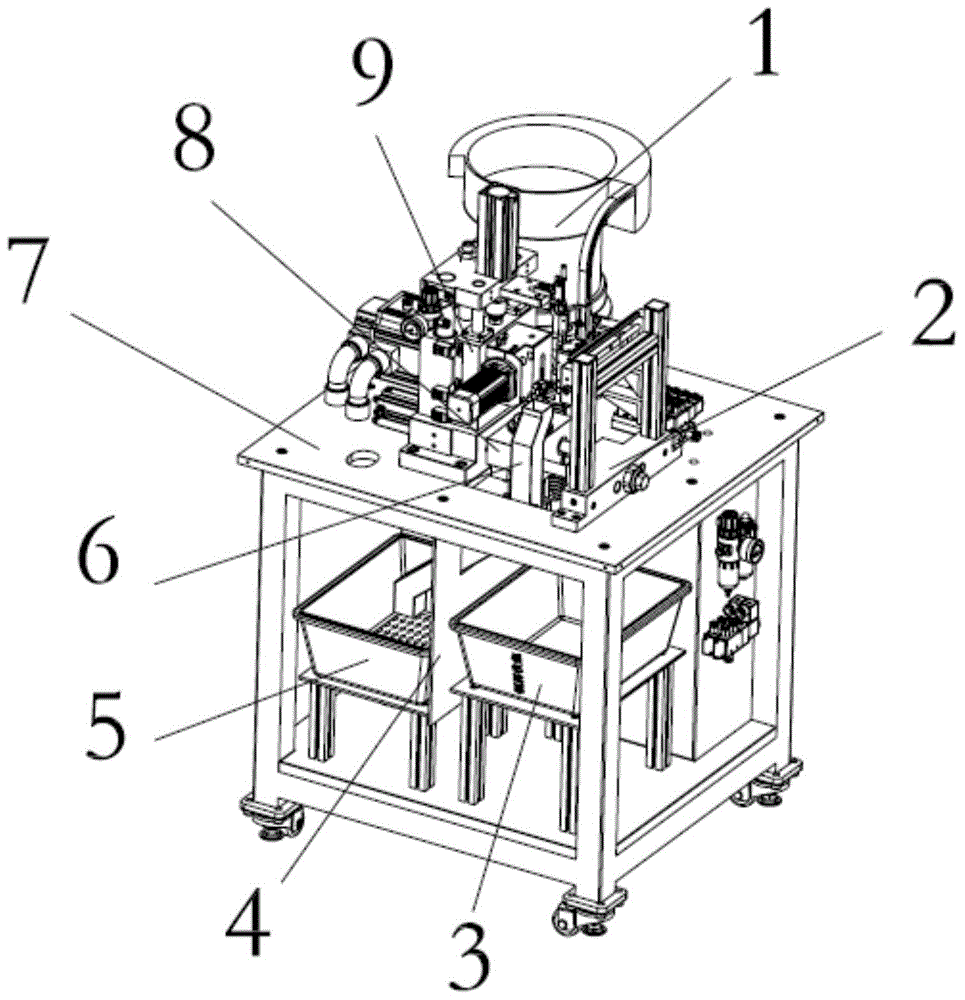

Mini-sized vertical slot milling machine

A vertical milling and grooving machine technology, applied in milling machine equipment, milling machine equipment details, metal processing machinery parts, etc., can solve the problem of reducing the production speed of slotted commutators, increasing the production rate of unqualified products, and destroying the commutator structure And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

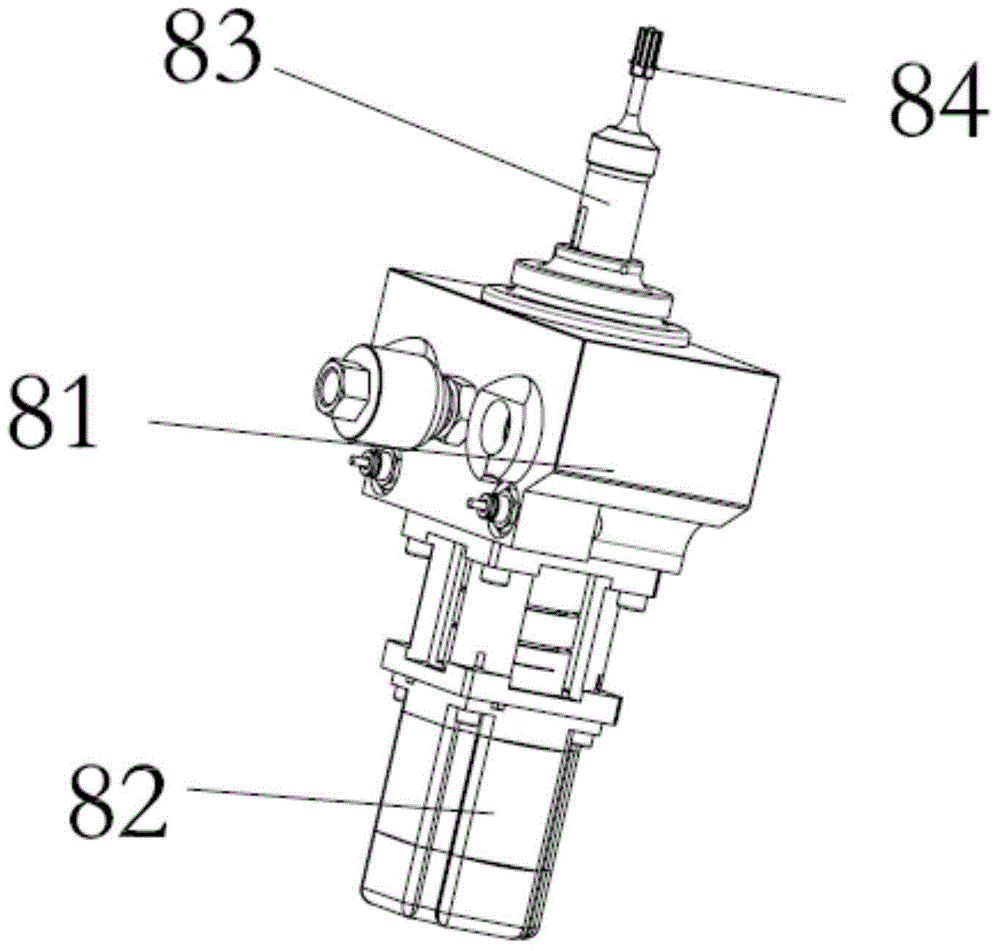

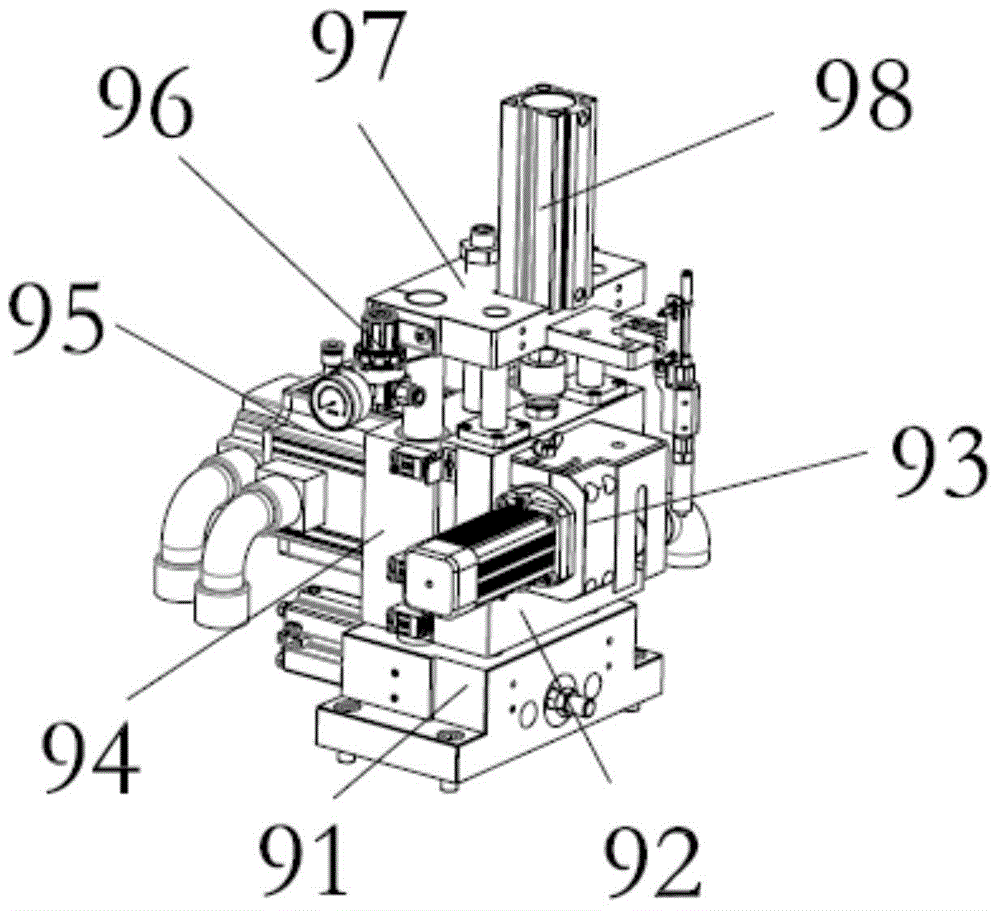

[0031]Place the commutator that has not been milled in the vibrating feeding tray 1. An optical fiber detection device is installed in the vibrating feeding tray 1 to reduce the wear of the commutator. Through the work of the vibrating feeding tray 1, the The commutators fall in a row along the feeding slide rail 11, and then the commutator stops falling through the material separation mechanism 27 on the feeding slide rail 11, and then the manipulator loading and unloading mechanism 2 starts, and the shifting manipulator 24 slides along the vertical slide rail bar 22, so that the vacuum feeding mechanism 26 installed horizontally at the lower end of the displacement manipulator 24 is located between the feeding positioning block 28 and the feeding slide rail 11, and then passes through the horizontal slide rail bar 23, Move the vacuum feeding mechanism 26 to the lower end of the feeding slide rail 11, then open the material separating mechanism 27, close the material separatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com