Quartz stone plate and its preparation method

A technology of quartz stone plate and pre-pressed plate, which is applied to flat products, other household utensils, applications, etc. It can solve the problems of difficulty in achieving continuous texture, inability to control texture, and rigid and rigid joints, so as to achieve stable process, realize mass production, The effect of continuous texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

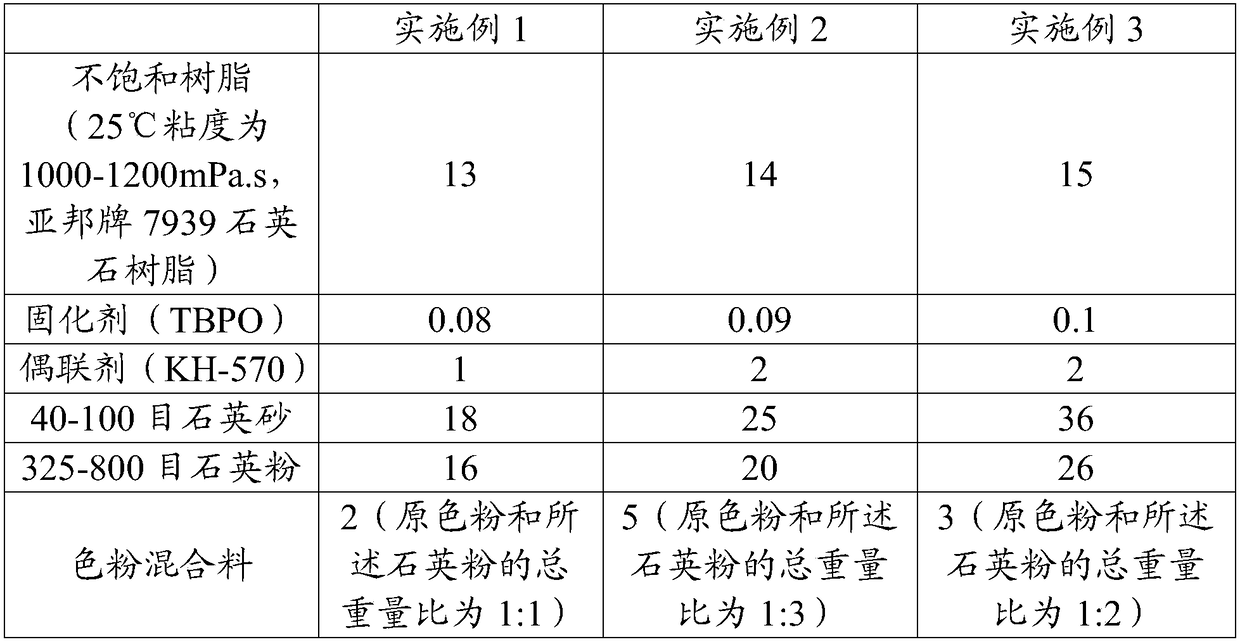

[0036] Three kinds of quartz stone plates in this embodiment, in parts by weight, include raw material components as described in Table 1:

[0037] Table 1

[0038]

[0039] The preparation method of described quartz stone plate, comprises the steps:

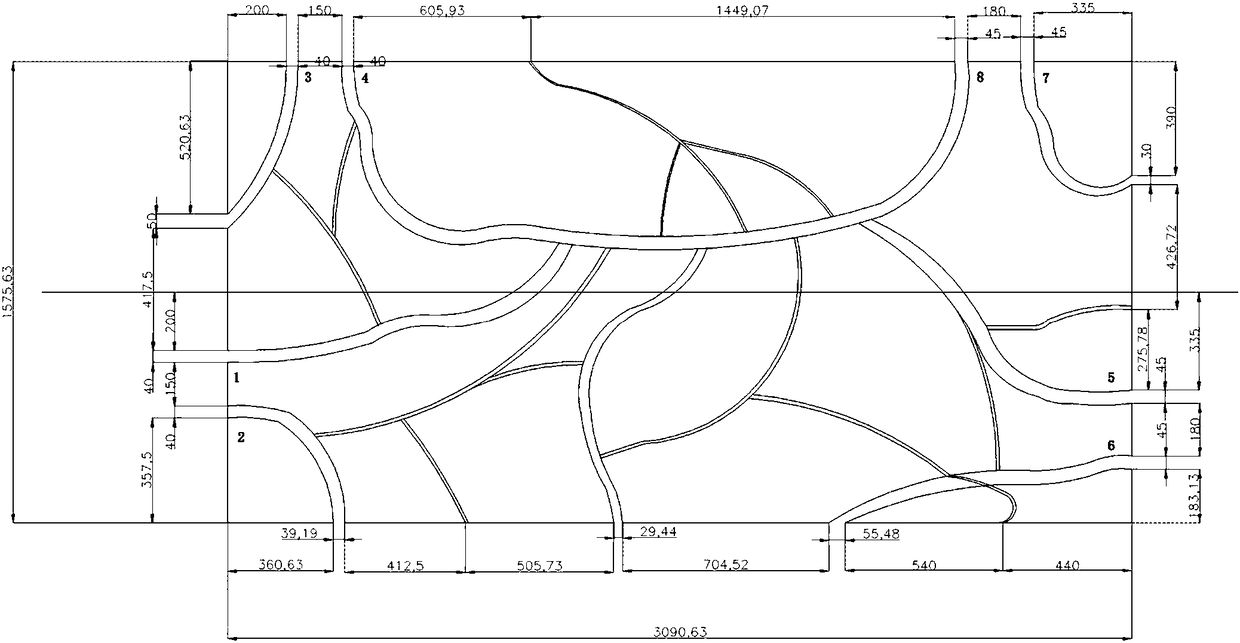

[0040] (1) Design the pre-pressing mold: set the linear first protrusion and the second protrusion on the pre-pressing plate with a length of 3090.63mm and a width of 1575.63mm, and the first protrusion and the second protrusion all protrude from the On the above surface, at least one end of the first protrusion extends to the edge of the pre-compression plate to form a splicing position, and the ends of the second protrusions are all located within the edge of the pre-compression plate, and the width of the splicing position is 29.44 -55.48mm, the quantity is 3 or 4 on the long side, 3 on the wide side, the distance between the splicing positions 1 and 2 on the left side is equal to the distance between the splicing positio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com