Formwork supporting rod

A formwork support and support rod technology, which is applied to the joints of formwork/formwork/work frame, the preparation of building components on site, construction, etc., can solve the problem of difficulty in accurately controlling the height of support rods, insufficient lighting at night, and reduced construction efficiency and other problems, to achieve the effect of facilitating long-distance transportation, simple construction technology, and ensuring safe construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

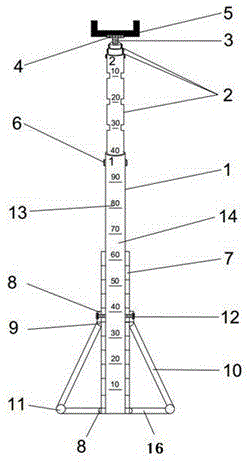

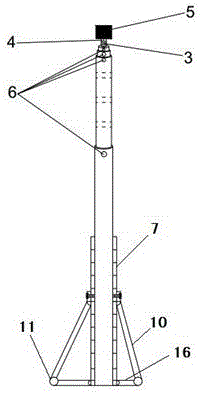

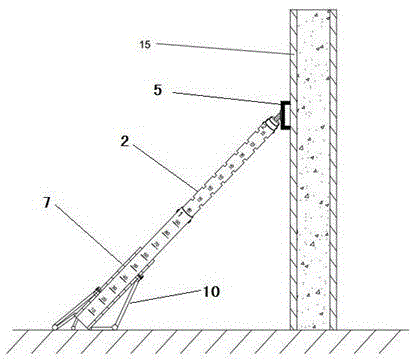

[0018] combine figure 1 , 2 , 3 to specifically illustrate the present invention, the inner cavity of the main pole (1) is provided with several telescopic poles (2) sequentially from the inside to the outside, the main pole (1) and the telescopic pole (2) There are several graduation marks (13) evenly on the outer wall, and several grooves are evenly distributed on the outer walls on both sides of the telescopic pole (2), and the top sides of the main pole (1) and the telescopic pole (2) are A spring snap button (6) is provided, and the spring snap button (6) matches the shape of the groove, and a fluorescent mark (14) is provided on the outer wall of the main pole (1) and the telescopic pole (2), The top of the innermost telescopic pole (2) is connected to the screw rod (3), and the top of the screw rod (3) is provided with a living hinge (4), and the top of the living hinge (4) is connected to a U-shaped support (5), The lower end of the main pole (1) is provided with thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com