Double-motor constant power synchronous control system free of rigid shaft connection

A technology of synchronous control and dual motors, which is applied in control system, AC motor control, multiple motor speed adjustment, etc. It can solve the problems of out-of-synchronization of output shaft position, large load, and inability to use constant power control, etc., to ensure position synchronization , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

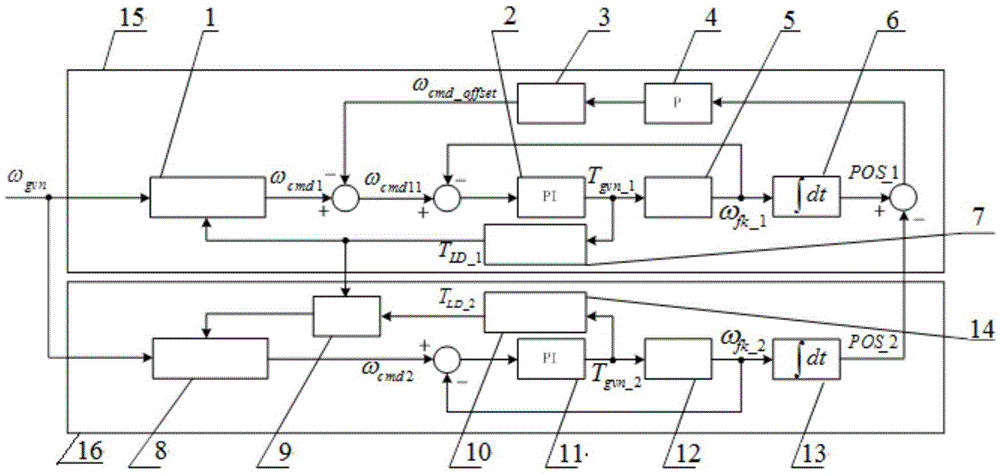

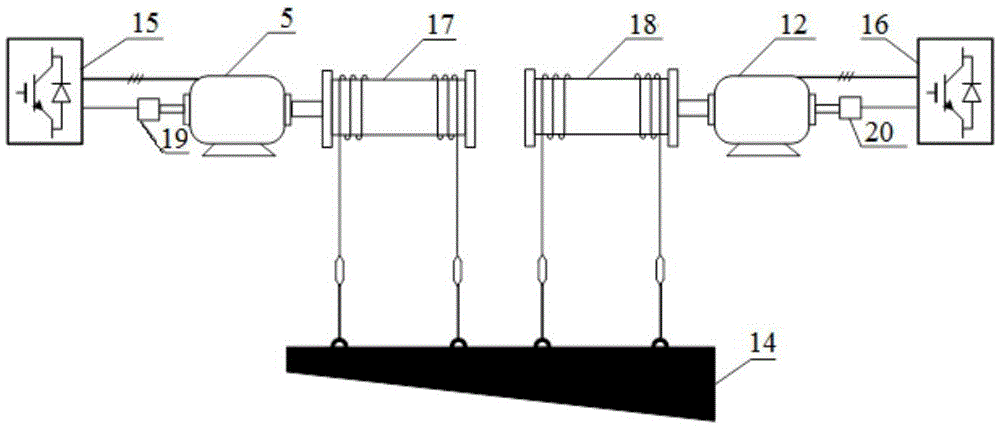

[0018] A dual-motor constant power synchronous control system without rigid shaft connection in this embodiment ( figure 1 ), including a master inverter 15 for driving the master motor 5 and a slave inverter 16 for driving the slave motor 12, the master inverter 15 includes a master maximum speed command generating unit 1, a master speed PI regulator 2, a master position control limiter Unit 3, master position control proportional unit 4, master speed variable position integral model 6, master load detection unit 7, slave maximum speed command generation unit 8, slave maximum load judgment unit 9, slave load detection unit 10, slave Speed PI regulator 11, slave speed variable position integral model 13. Apply this system to two motors to jointly lift the same heavy object with uneven mass distribution 14( figure 2 ), the main motor 5 drives the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com