Phase-shifting output control circuit and operating method thereof

An output control and phase-shifting technology, applied in the field of phase-shifting output control circuit, can solve problems such as complex structure, easy misconnection, cumbersome wiring, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

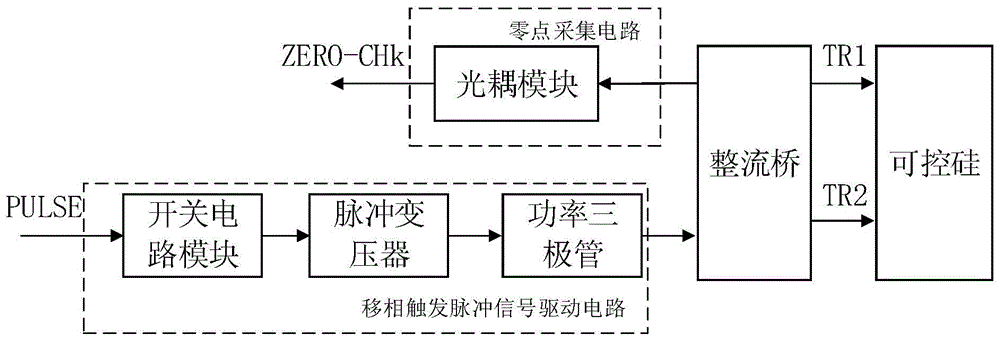

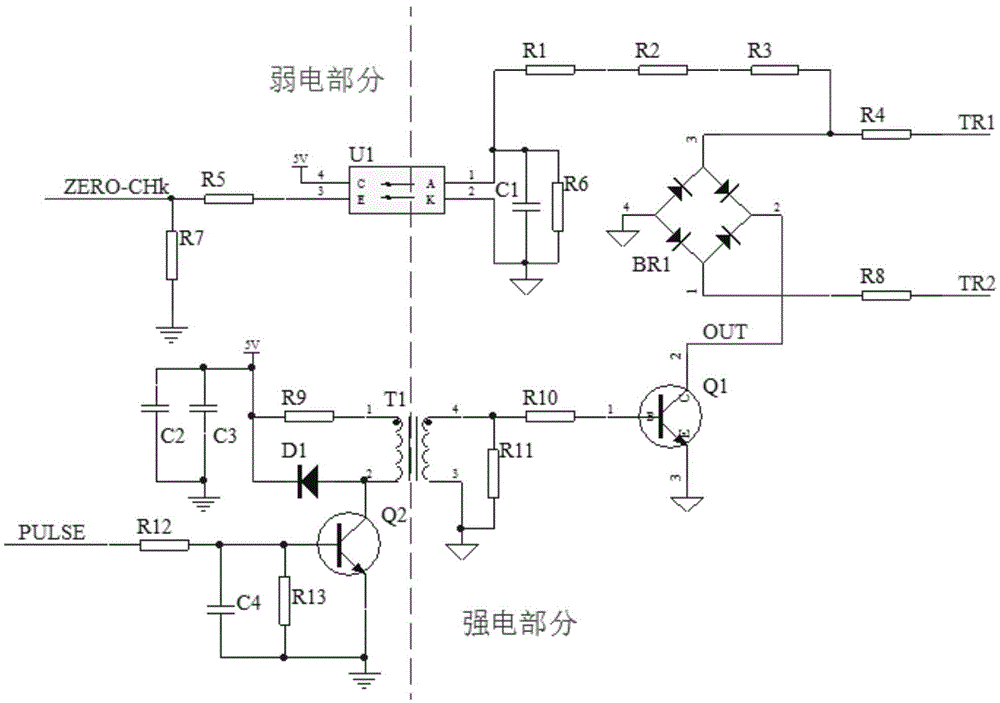

[0021] Such as figure 1 As shown, a phase-shifted output control circuit of the present invention includes: a phase-shifted trigger pulse signal drive circuit, the output end of the phase-shifted trigger pulse signal drive circuit is connected to the common cathode of the rectifier bridge BR1, and the rectifier bridge BR1 is also connected respectively SCR and zero point acquisition circuit.

[0022] When the phase shift trigger pulse PULSE is high, the phase shift trigger pulse signal drive circuit outputs a low level to the common cathode of the rectifier bridge BR1 to trigger the conduction of the thyristor, and the mains voltage across the thyristor is 0V;

[0023] When the phase-shift trigger pulse PULSE is low, the phase-shift trigger pulse signal drive circuit has no output, and the thyristor is cut off, that is, both ends of the thyristor can restore the mains voltage, and when the mains voltage is in the positive half cycle, drive zero point acquisition The circuit obtains...

Embodiment 2

[0035] On the basis of Embodiment 1, Embodiment 2 provides a working method of a phase shift output control circuit.

[0036] The phase shift output control circuit is as described in the first embodiment.

[0037] Such as figure 1 with figure 2 As shown, the working method includes:

[0038] When the phase-shift trigger pulse PULSE is at a high level, the phase-shift trigger pulse signal driving circuit outputs a low level to the common cathode of the rectifier bridge BR1 to trigger the conduction of the thyristor; and

[0039] When the phase-shift trigger pulse PULSE is low, the phase-shift trigger pulse signal drive circuit has no output, and the thyristor is cut off, that is, both ends of the thyristor can restore the mains voltage, and when the mains voltage is in the positive half cycle, drive zero point acquisition The circuit obtains the zero acquisition signal ZERO-CHk.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com