Wheel and method for manufacturing wheel

A wheel and rim technology, applied in the field of automobile wheels, to achieve good stiffness characteristics, weight reduction, and material saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

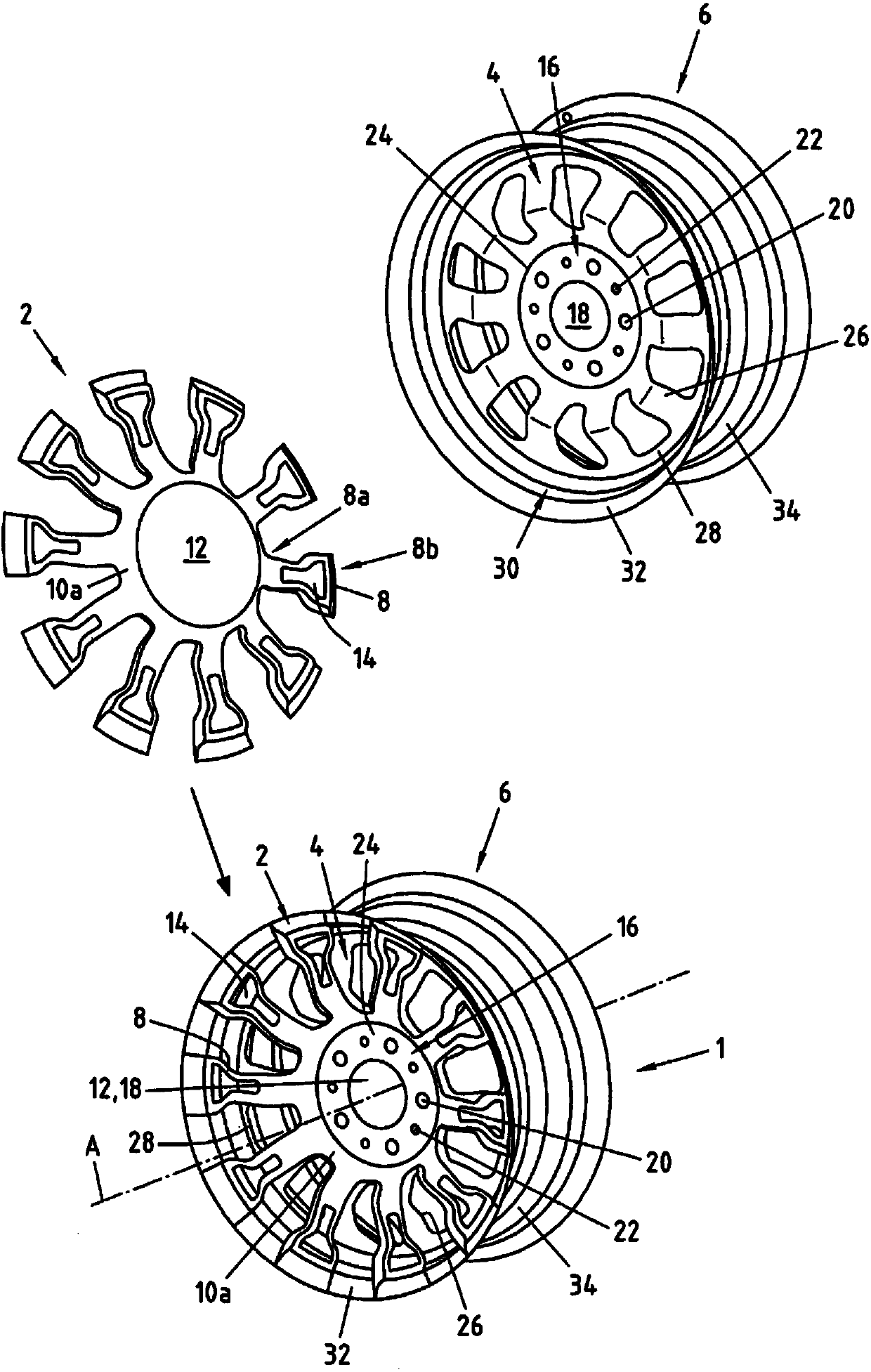

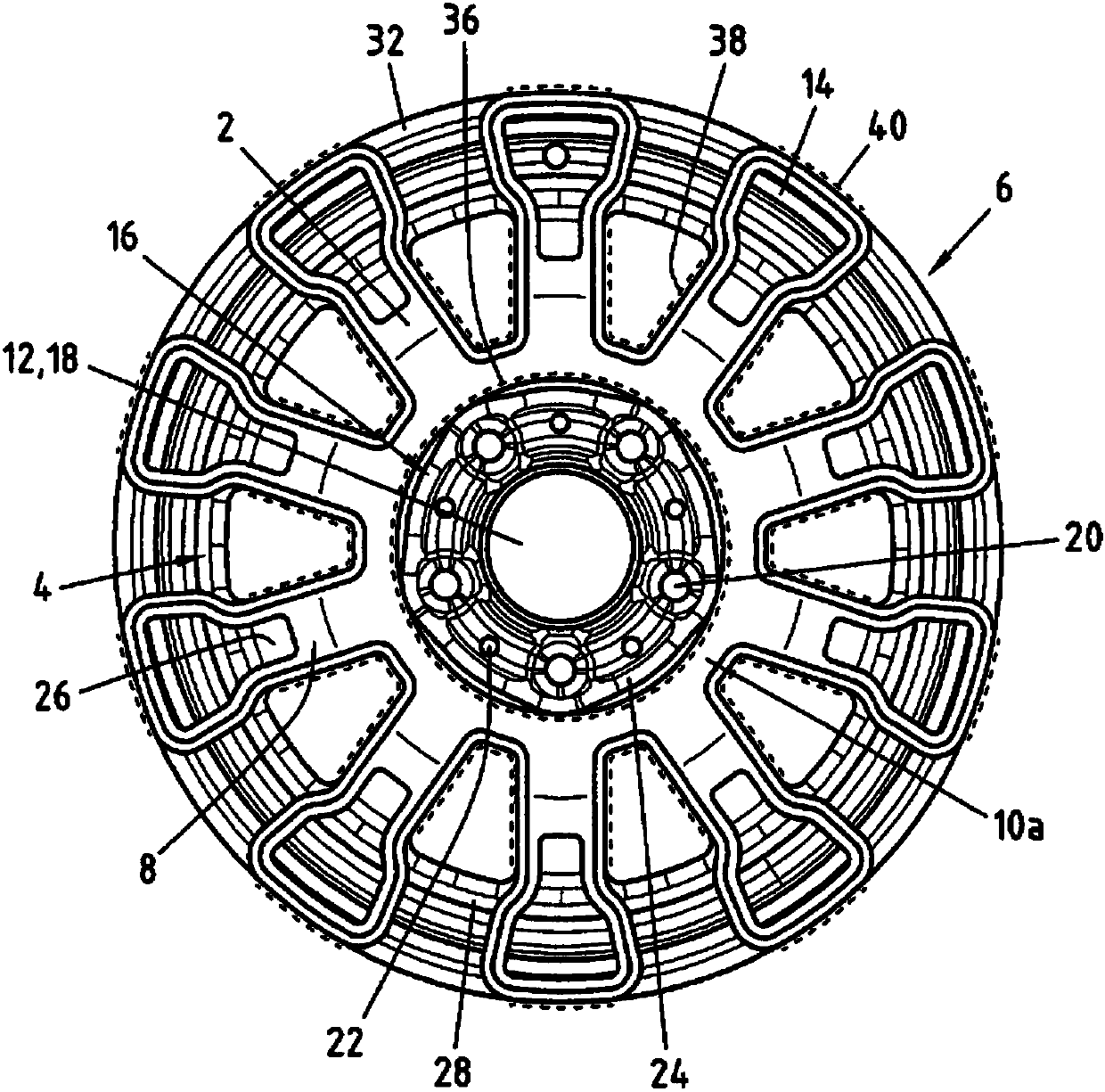

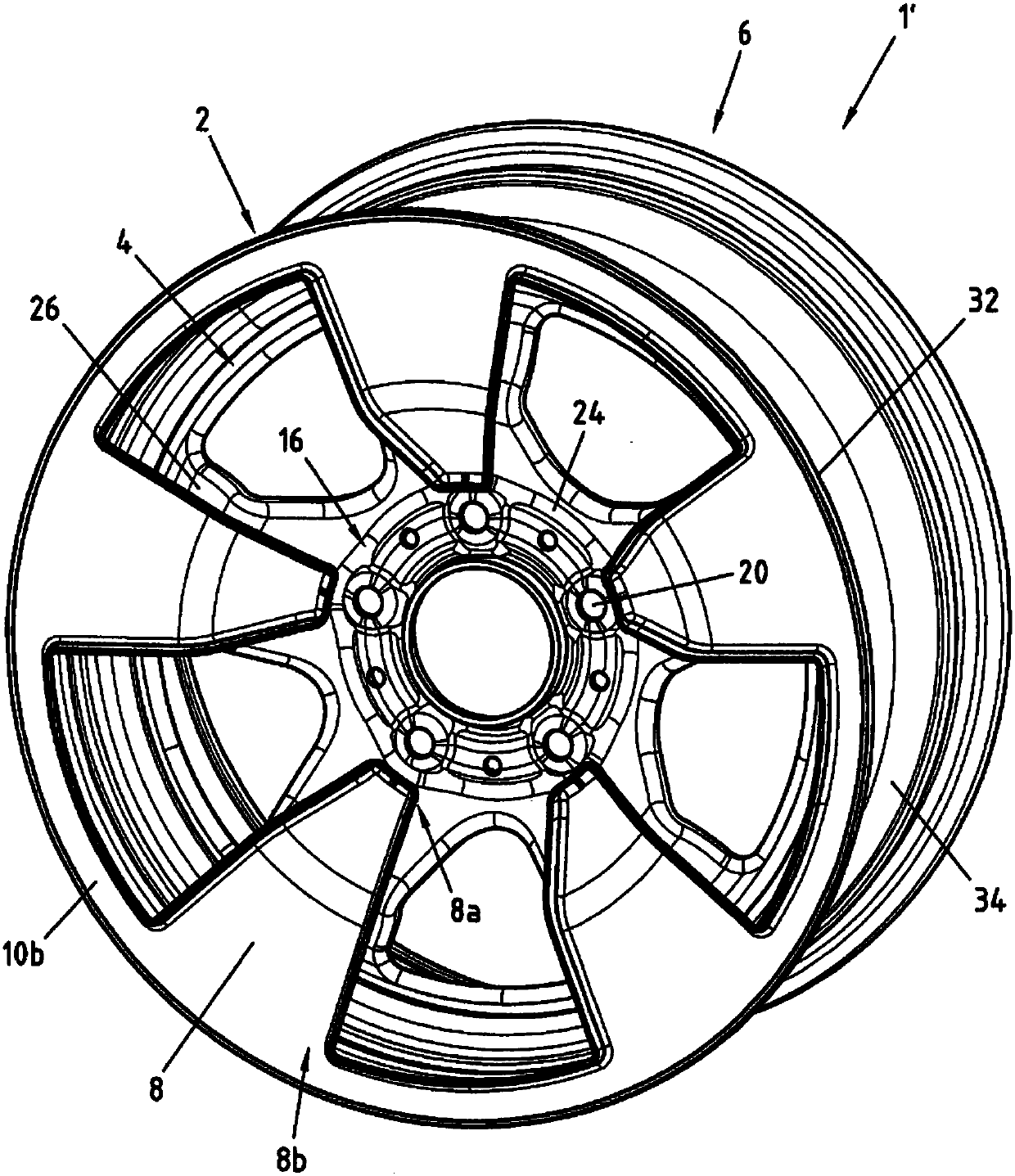

[0051] figure 1 The method for producing the wheel 1 is schematically shown. On the one hand, the cover shell 2 is shown, and on the other hand, the main frame 4 is shown together with the rim lock ring 6 (the rim lock ring and the main frame are already connected to each other). The cover shell 2 is combined with the composite structure of the main frame 4 and the rim lock ring 6 to form the wheel 1 shown, as indicated by the arrows.

[0052]In this exemplary embodiment, the cover shell 2 is embodied as a spoke structure and has spokes 8 of the same design. In this case ten spokes are provided, but other numbers can also be provided. The spokes 8 extend substantially radially, wherein the spokes 8 are connected to the annular region 10 a at their radially inner ends 8 a. The annular region 10 a thus delimits a central, circular opening 12 . The annular area serves as a potential connection area of the cover shell 2 to the main frame 4 . The radially outer ends 8 b of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com