Energy-saving power supply system for strawberry planting greenhouse

A technology for water supply system and greenhouse, applied in the field of energy-saving water supply system for strawberry planting greenhouses, can solve the problems of unadjustable water volume, easy leakage of control valve, etc., to avoid rust or corrosion, avoid water flow out, and prolong the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

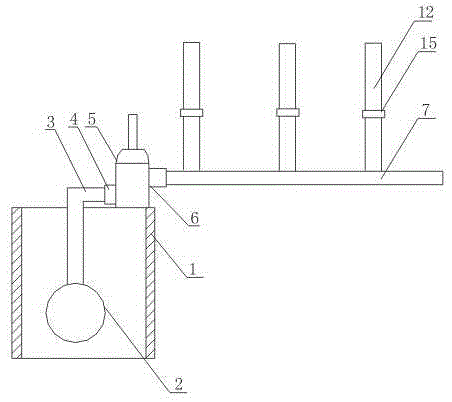

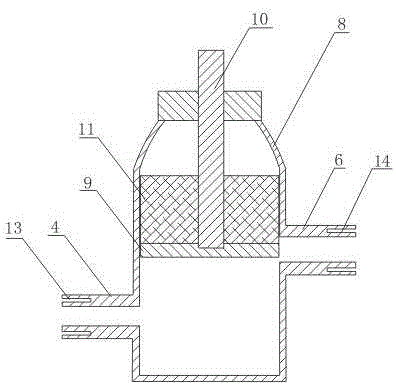

[0023] Such as figure 1 , figure 2 As shown, the energy-saving water supply system for strawberry planting greenhouses includes a water pump 2 arranged in a water well 1, a water pipeline 3 connected to the water pump 2, a control valve 5 connected to the water inlet 4 and the water pipeline 3, and a control valve 5 The transmission pipe 7 connected to the water outlet 6; the control valve 5 includes a valve body 8, a valve core 9 installed in the inner cavity of the valve body 8, and a valve stem 10 connected to the valve core 9, and the upper surface of the valve body 8 is provided with threads hole, the valve stem 10 is a screw structure that matches the threaded hole, and one end of the valve stem 10 passes through the threaded hole on the upper surface of the valve body 8 and is arranged outside the valve body 8; the water inlet 4 and the water outlet 6 are respectively arranged on the valve body 8 It also includes a water-absorbing expansion body 11 arranged at the joi...

Embodiment 2

[0026] On the basis of Embodiment 1, this embodiment also includes several branch water pipes 12 arranged on the transmission pipeline 7 .

[0027] The branch water pipe 12 in the present embodiment increases the irrigation area and ensures that the strawberries in the greenhouse are evenly watered.

Embodiment 3

[0029] In this embodiment, on the basis of Embodiment 1 or Embodiment 2, the outer end surface of the water inlet 4 is provided with a clamping groove A13, and the outer end surface of the water outlet 6 is provided with a clamping groove B14; the water delivery pipeline 3 is clamped. In the slot A13, the transmission pipe 7 is locked in the slot B14.

[0030] The clamping slot A13 and the clamping slot B14 in this embodiment are respectively used for clamping the water delivery pipeline 3 and the transmission pipeline 7, so that disassembly is convenient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com