Energetic material for cigarette and low-temperature heated cigarette

A technology for cigarettes and raw materials, applied in the directions of tobacco, application, and cigar manufacturing, can solve the problems of easy shedding of heat sources, easy shedding, and shedding and being adsorbed to the side of the filter, so as to avoid the effect of excessive production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The energetic material in this embodiment is processed by mixing the following raw materials in mass fraction: 45% potassium nitrate, 30% charcoal powder, 14% guar gum, 2% iron oxide, 7% graphite, and 2% lecithin.

[0036] The combustion temperature of the energetic material is about 600°C.

[0037] The burning rate of the energetic material is 1.5 mm / min.

[0038] The combustion heat release amount of the energetic material is 15KJ / g.

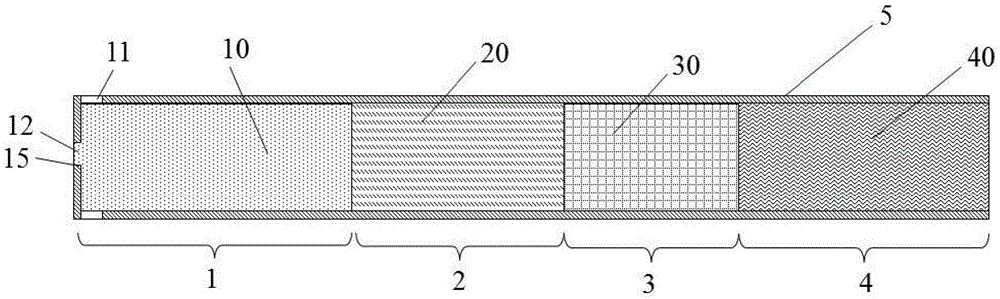

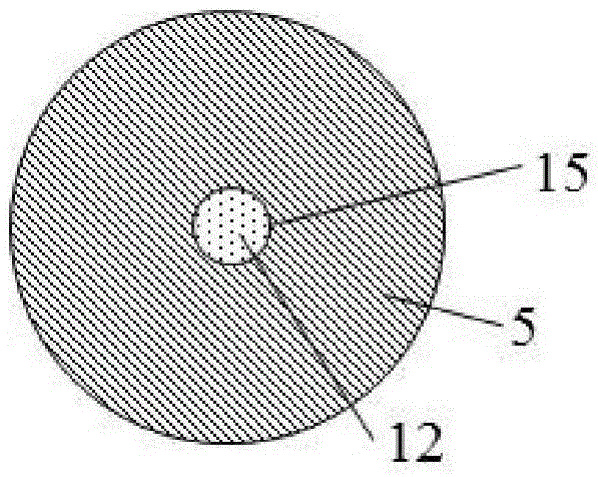

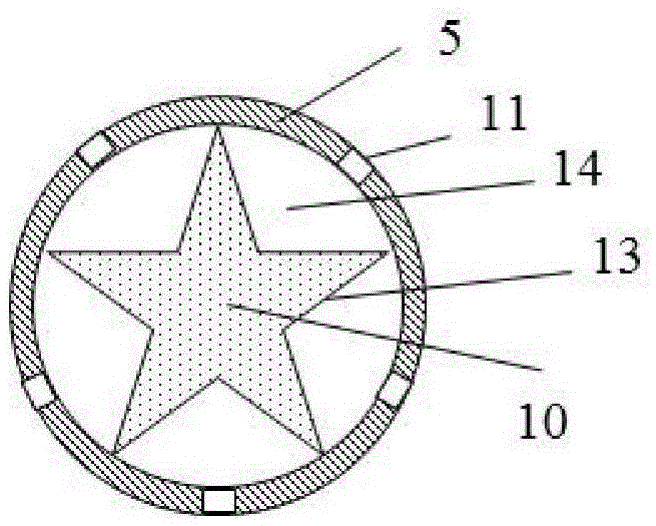

[0039] see figure 1 , figure 2 , image 3 and Figure 4 In this embodiment, the low-temperature heating cigarette containing the above-mentioned energetic material consists of a heat-insulating ceramic sleeve 5 and a heat source area 1, an aerosol generating area 2, and a fragrance Occurrence area 3, mouthpiece area 4 composition.

[0040] A five-pointed star-shaped copper barrel 13 is arranged in the heat source area 1, and the pentagons of the five-pointed star-shaped copper barrel 13 are in contact with the pipe wall of the he...

Embodiment 2

[0046] The energetic material in this embodiment is processed by mixing the following raw materials in mass fraction: 55% nitroglycerin, 30% pectin, 2% copper oxide, 10% diatomaceous earth, and 3% lecithin.

[0047] The combustion temperature of the energetic material is about 500°C.

[0048] The burning rate of the energetic material is 1.0 mm / min.

[0049] The combustion heat release of the energetic material is 20KJ / g.

[0050] see figure 1 , figure 2 , image 3 and Figure 4 In this embodiment, the low-temperature heating cigarette containing the above-mentioned energetic material consists of a heat-insulating ceramic sleeve 5 and a heat source area 1, an aerosol generating area 2, and a fragrance Occurrence area 3, mouthpiece area 4 composition.

[0051] A five-pointed star-shaped copper barrel 13 is arranged in the heat source area 1, and the pentagons of the five-pointed star-shaped copper barrel 13 are in contact with the pipe wall of the heat-insulating ceramic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com